Continuous feed tablet coating system

a coating system and feed tablet technology, applied in coatings, granule coatings, sweetmeats, etc., can solve the problems of reducing the efficiency of coating process, affecting the consistency of coating process, and affecting the quality of coating, so as to achieve the effect of reducing the waste of coating fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

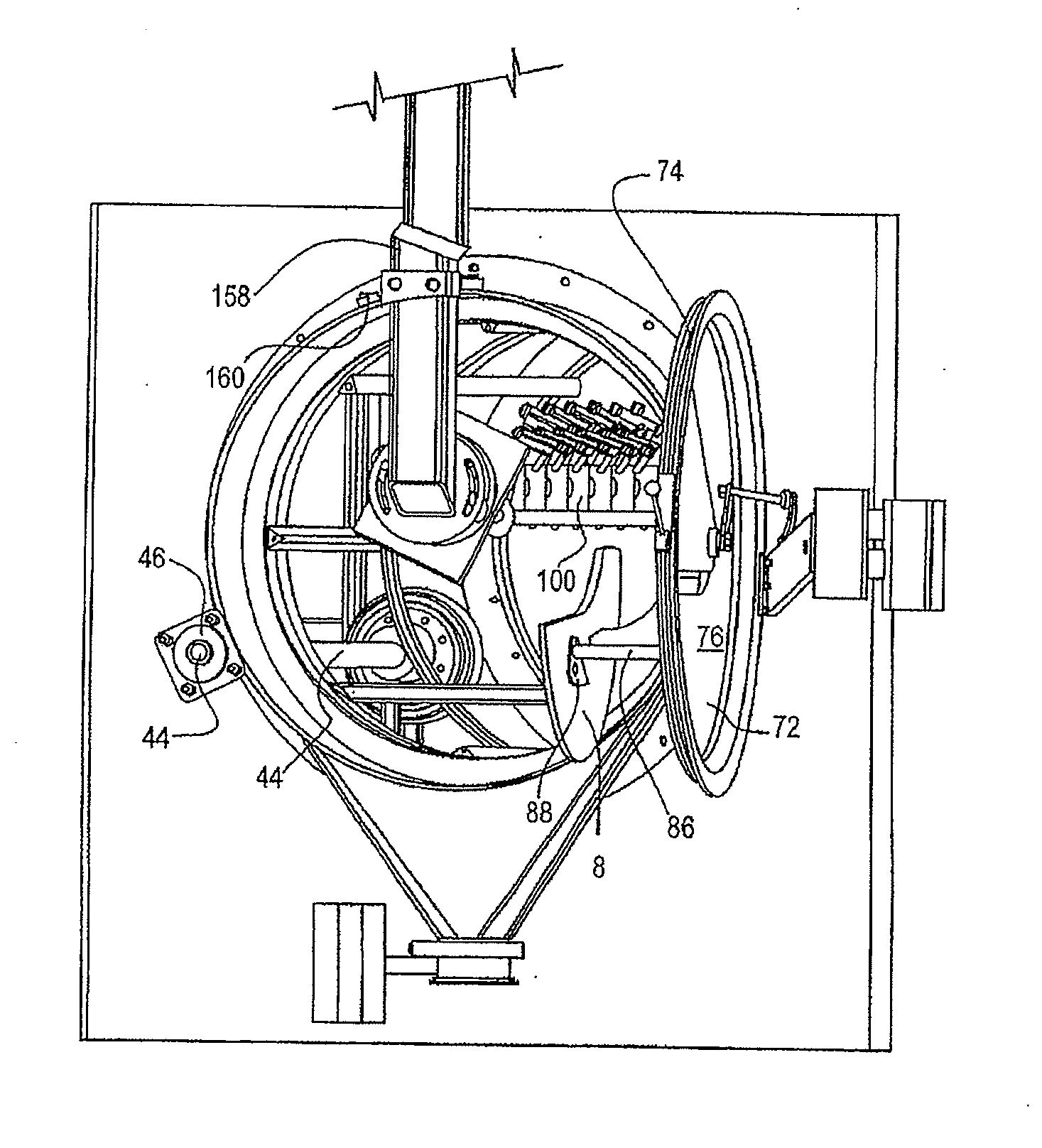

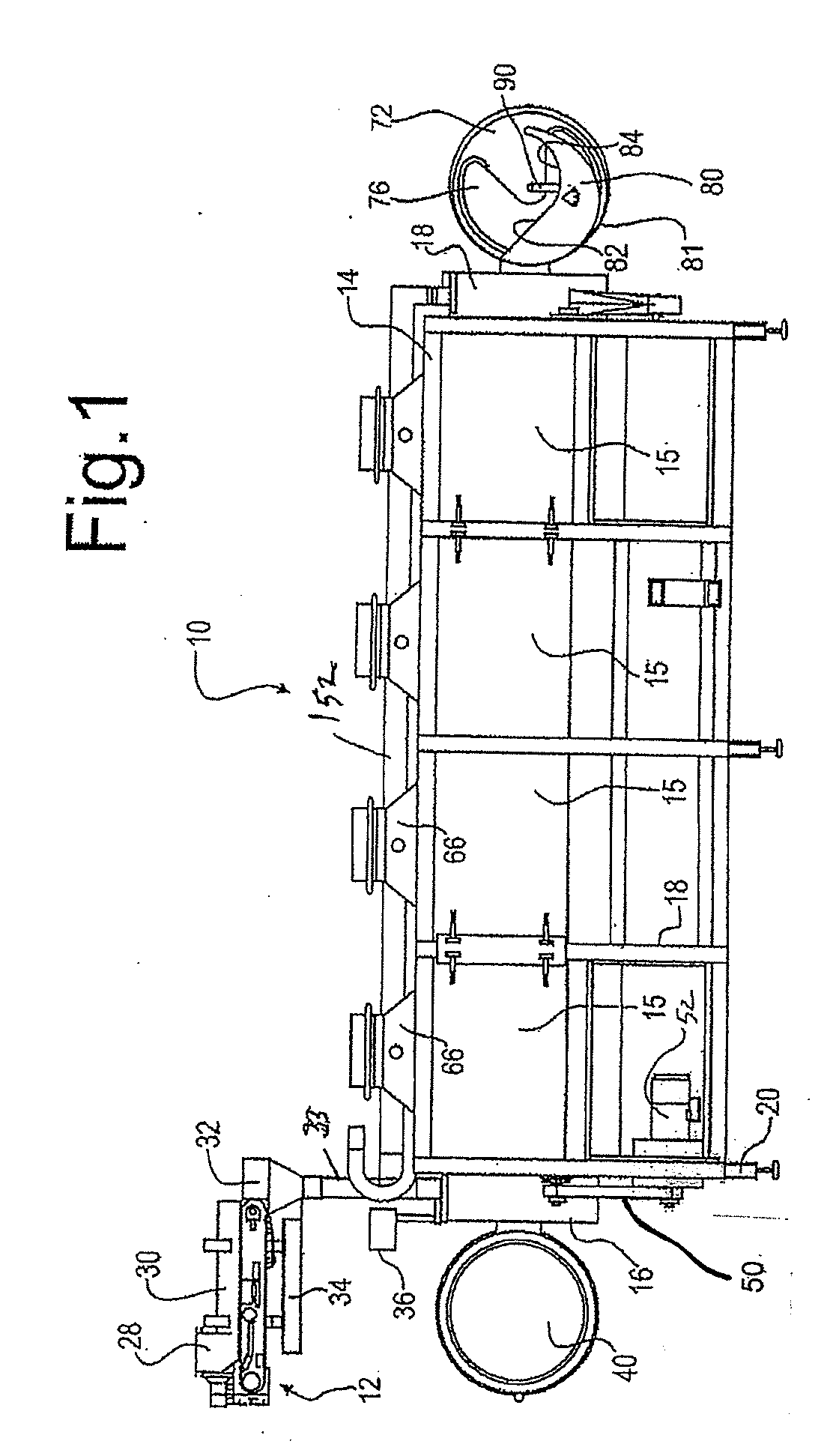

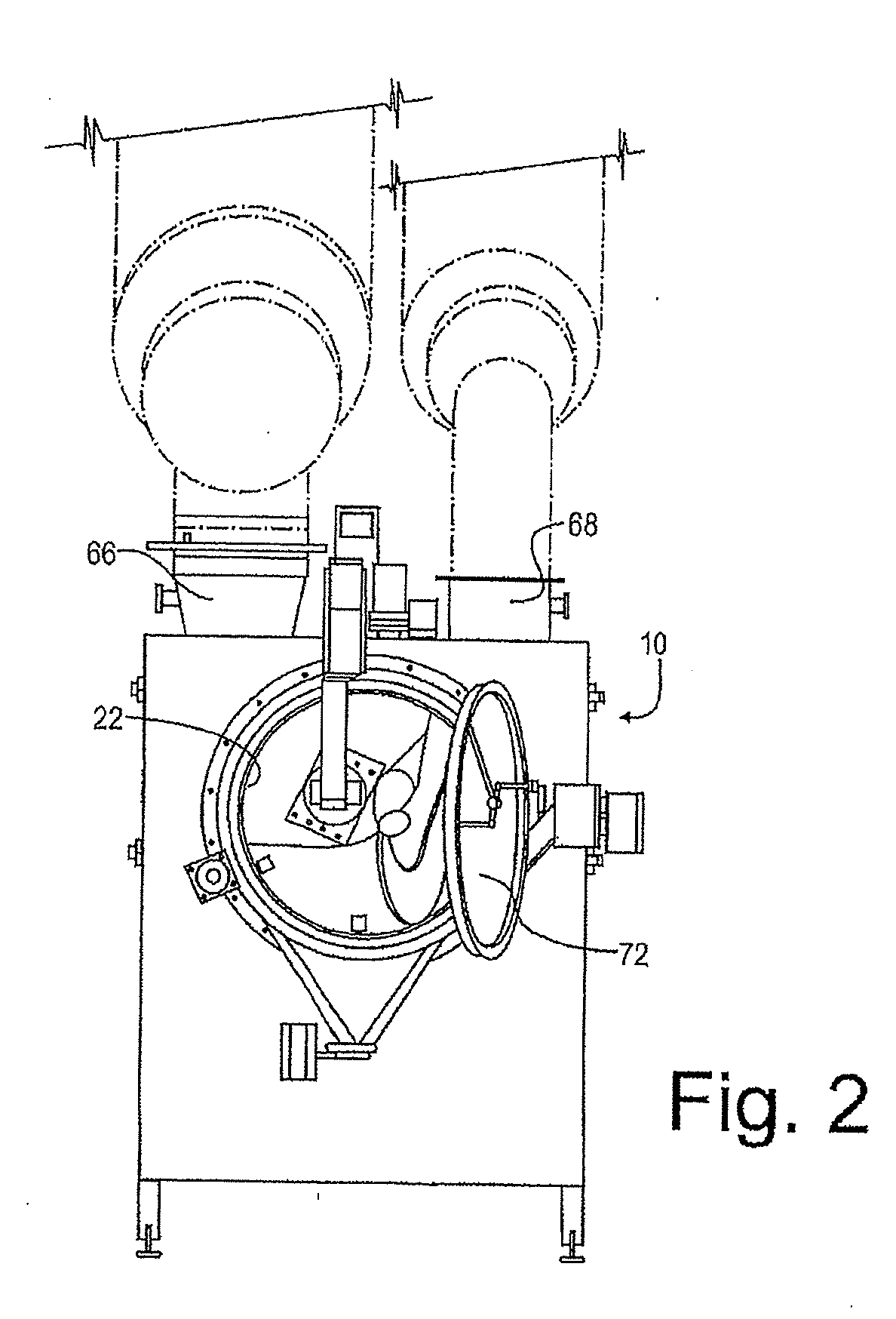

[0041]The tablet coating system 10 described herein as one embodiment of the invention comprises in general terms a weigh in-feed conveyor 12, a housing 14, a tablet inlet chamber 16 and a coated tablet discharge region 18 for discharging coated tablets from the system. The housing 14 is supported by a frame 19, including length-adjustable legs 20 for leveling the system. Housing 14 fully encloses a horizontal-axis perforated rotatable stainless steel drum 22, seen in detail in FIG. 7. Drum 22 is open-ended at both opposed ends. Access to the interior of housing 14 is obtained by an array of doors 15 on both lateral sides of the housing. As well, front and rear ports within the end walls, covered by front and rear end doors 40 and 72 provide access from the respective ends of housing 14. All doors of the housing are sealed with inflatable seals. Housing 14 is generally elongate, with a central axis extending between the opposed ends thereof.

[0042]In-feed conveyor 12 comprises a comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com