Hydrothermal Power Plant

a technology of hydrothermal power plant and power generation system, which is applied in the direction of steam engine plant, machine/engine, supercritical condition process, etc., can solve the problems of poor efficiencies of scwor that have not made commercially viable, lack of actual implantation of scwor designs in patent literature, and low efficiency of conventional fuels. , to achieve the effect of high thermal efficiency and use of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

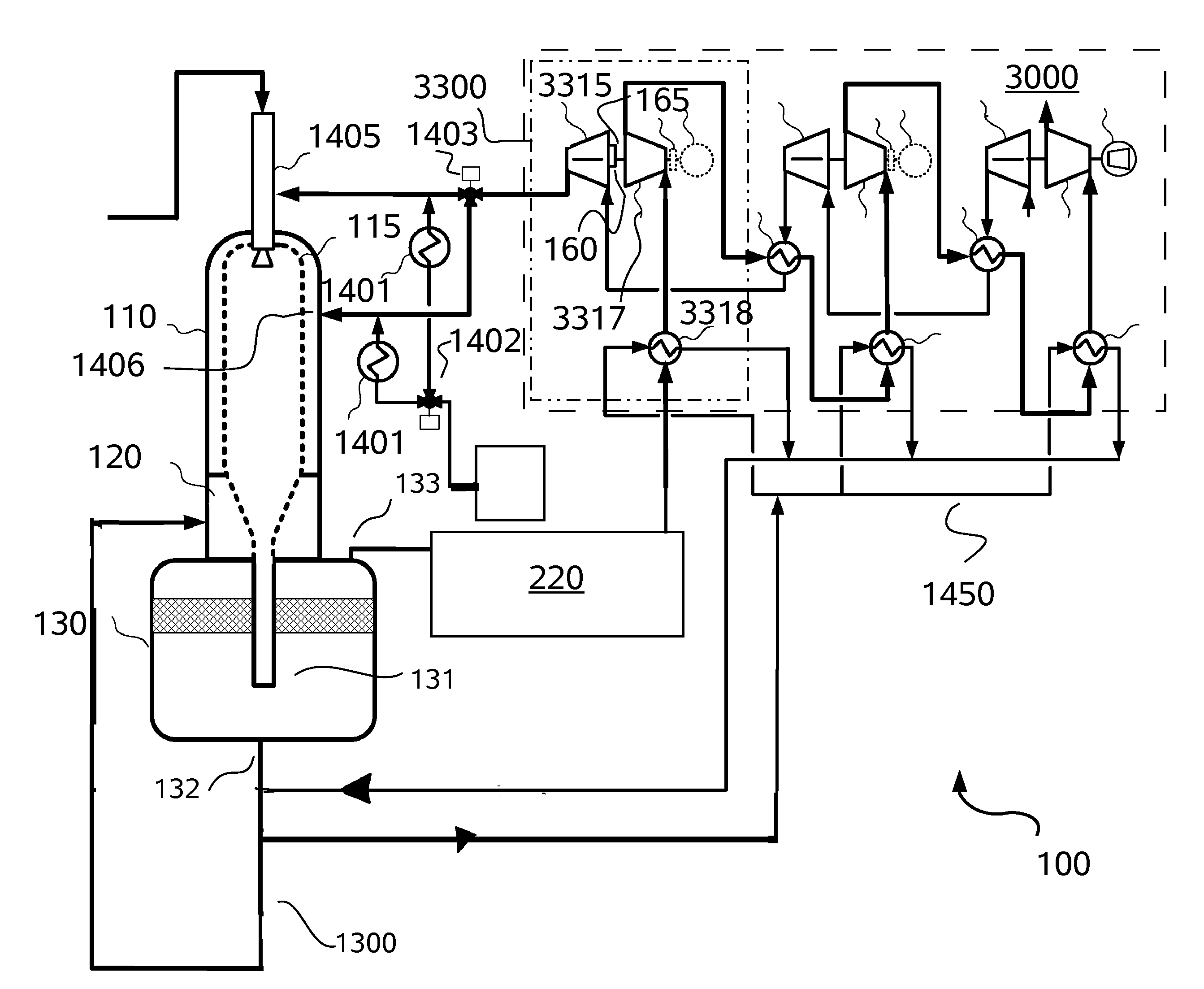

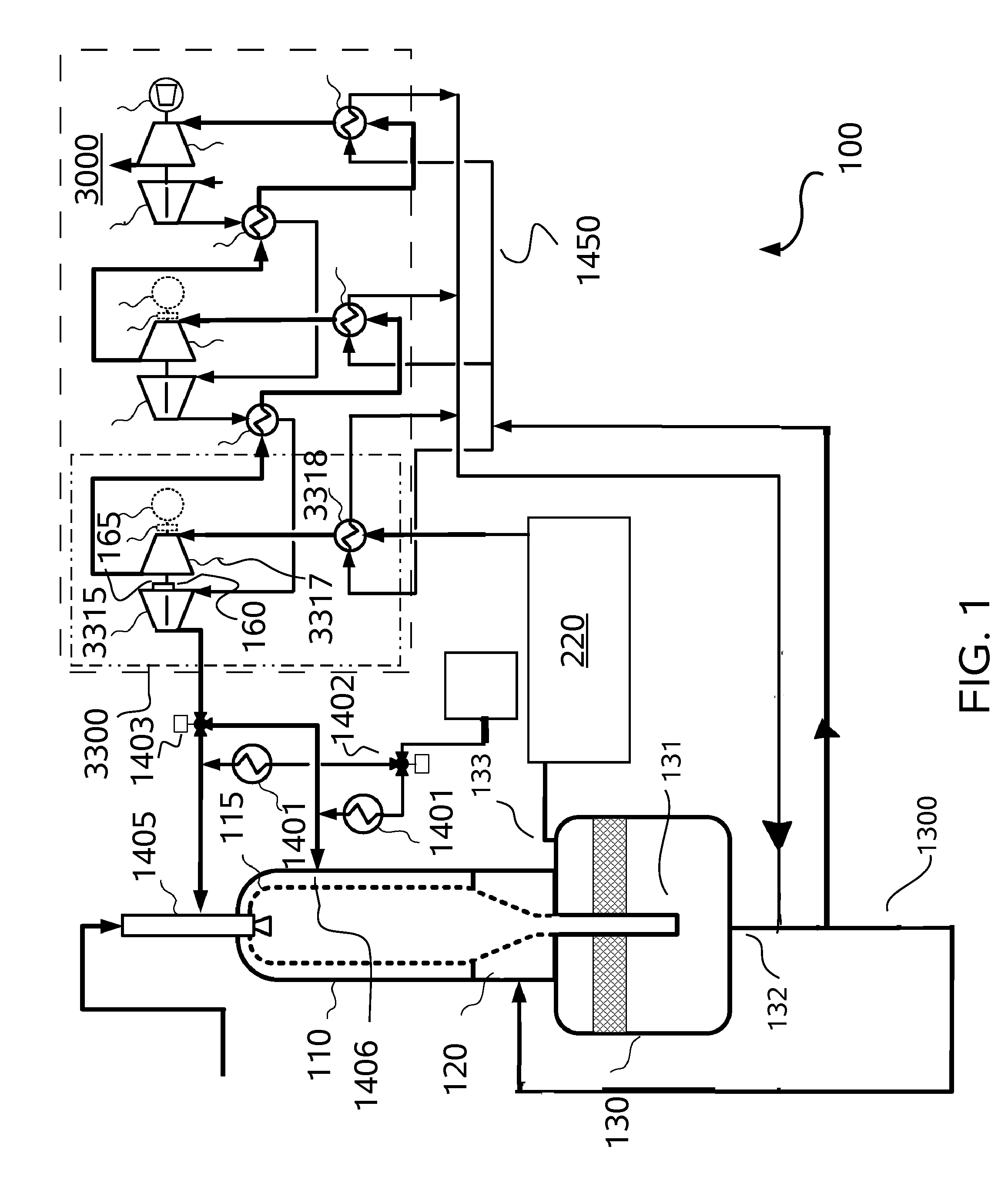

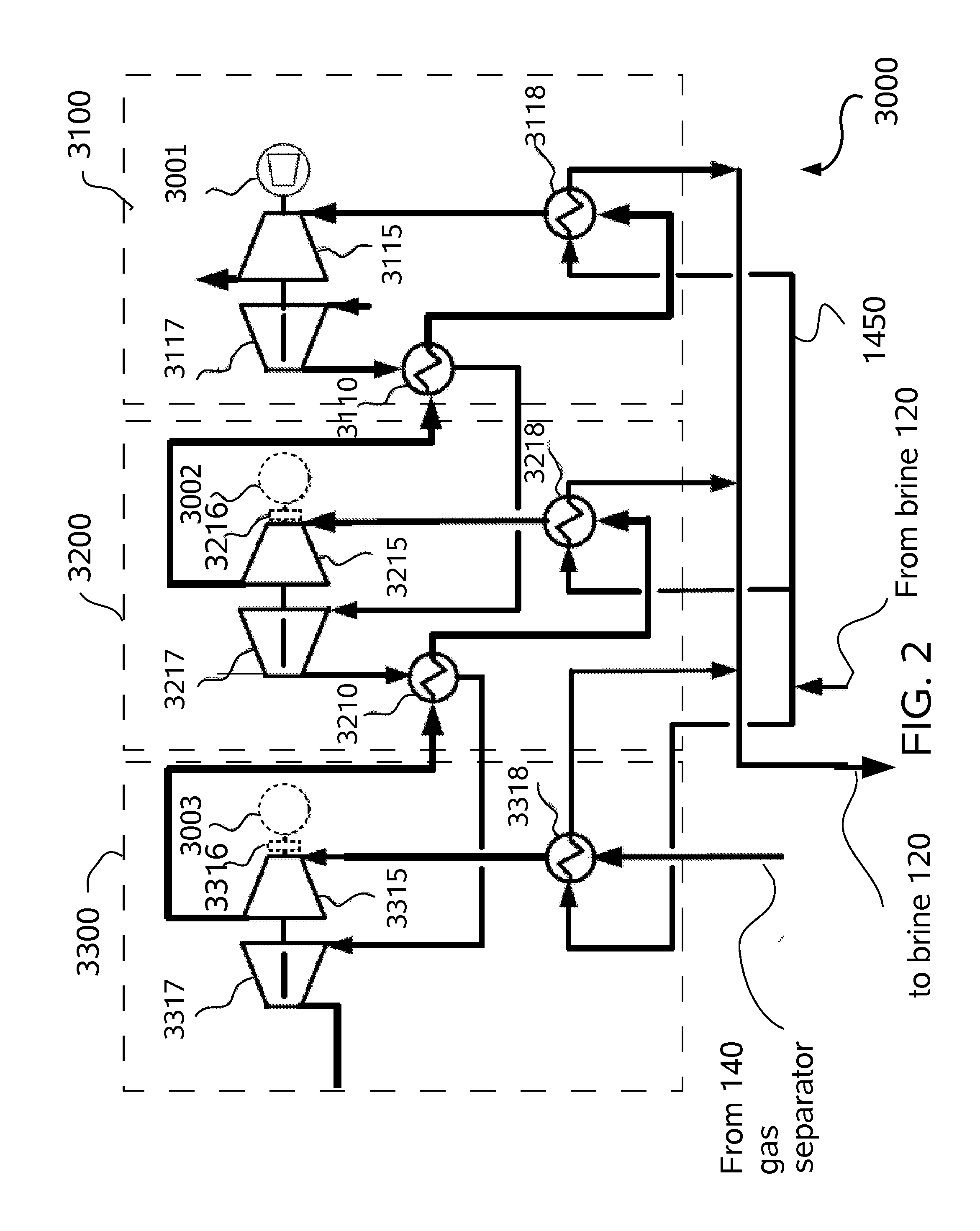

[0024]Referring to FIGS. 1 through 9, wherein like reference numerals refer to like components in the various views, there is illustrated therein a new and improved Hydro-Thermal Power Plant (HTPP) generally denominated 100 herein.

[0025]In accordance with the present invention, FIG. 1 illustrates a HTPP 100 that comprises a super critical water oxidation reactor (SCWOR) 110. At the super critical conditions the organic materials that enter the SCWOR 110 are oxidized, as are described for example in U.S. Pat. Nos. 5,558,783 (issued to McGuinness on Sep. 24, 1996) and 5,384,051 (issued to McGuinness on Jan. 24, 1995), which are incorporated herein by reference. This oxidation reaction generates heat that is used to generate electrical power in the HTTP 100 as described further below. The SCWOR 100 preferably incorporates a permeable-wall or transpiring wall 115. The SCWOR 110 may be operated at pressures above or below the critical pressure or water.

[0026]In a currently preferred mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com