Sidewall blank for substantially eliminating twist in deep bottom containers

a technology of sidewall blanks and containers, applied in the field of two-piece, seamed paper cups coated with therm, can solve problems such as potential leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

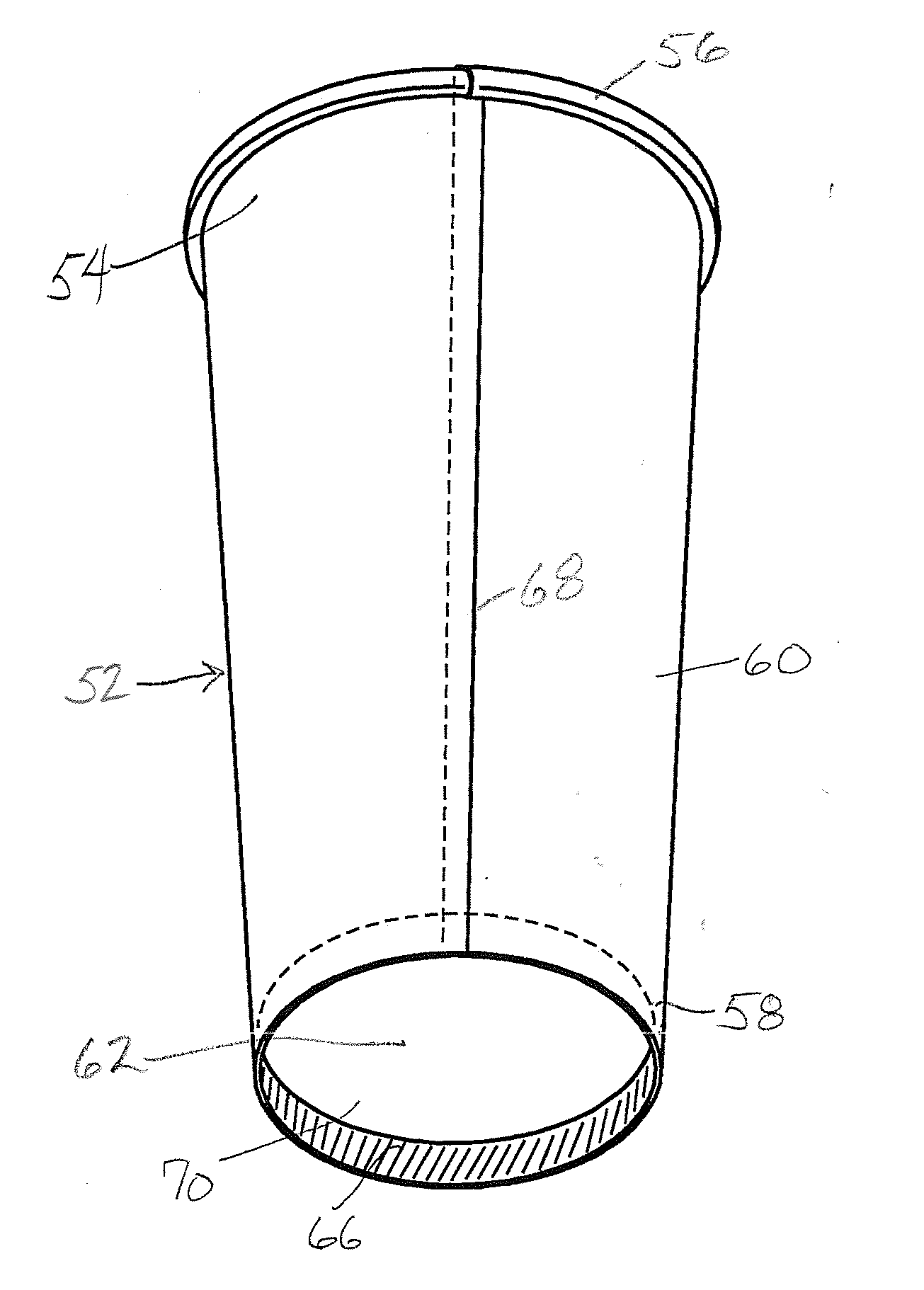

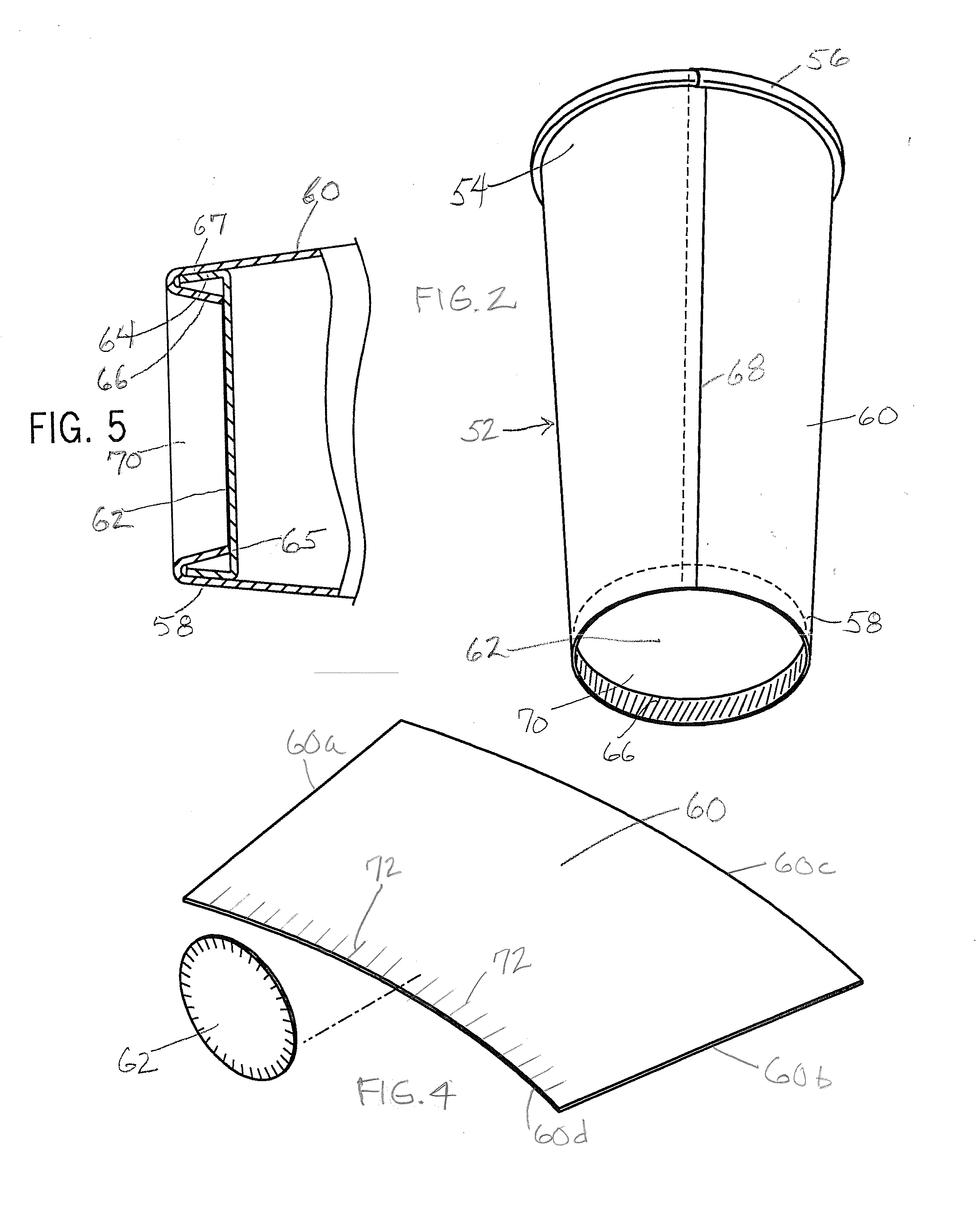

[0018]Referring generally to FIG. 3, an exemplary cup making machine 20 is illustrated. This particular design includes a mandrel turret 22 which cooperates with a transfer turret 24 and a rimming turret 26. Mandrel turret 22 includes a plurality of mandrels 28 that are rotated in a stepwise or indexing manner between a surrounding workstations. For example, a bottom blank may be applied to a given mandrel 28 at a bottom blank maker workstation 30 and then rotated to a bottom reformer station 32. From this point, the mandrel 28 is rotated into cooperation with the transfer turret 24 which receives sidewall blanks from a hopper 34 and rotates the sidewall blank into cooperation with an adjacent mandrel 28. The sidewall blank is then folded about the mandrel over the bottom blank, heated and sealed along a side seam where the opposite side edges of the sidewall blank overlap.

[0019]Next, the bottom blank and the sidewall blank are rotated to a bottom heat station 36. After heating, man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com