Frame-mounted laser aiming device

a laser aiming device and frame technology, applied in the field of firearm laser aiming devices, can solve the problems of inability to reduce the constant distance of deviation, inconvenient installation and/or replacement, and inability to significantly affect so as to achieve the effect of not significantly affecting the weight or balance of the firearm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

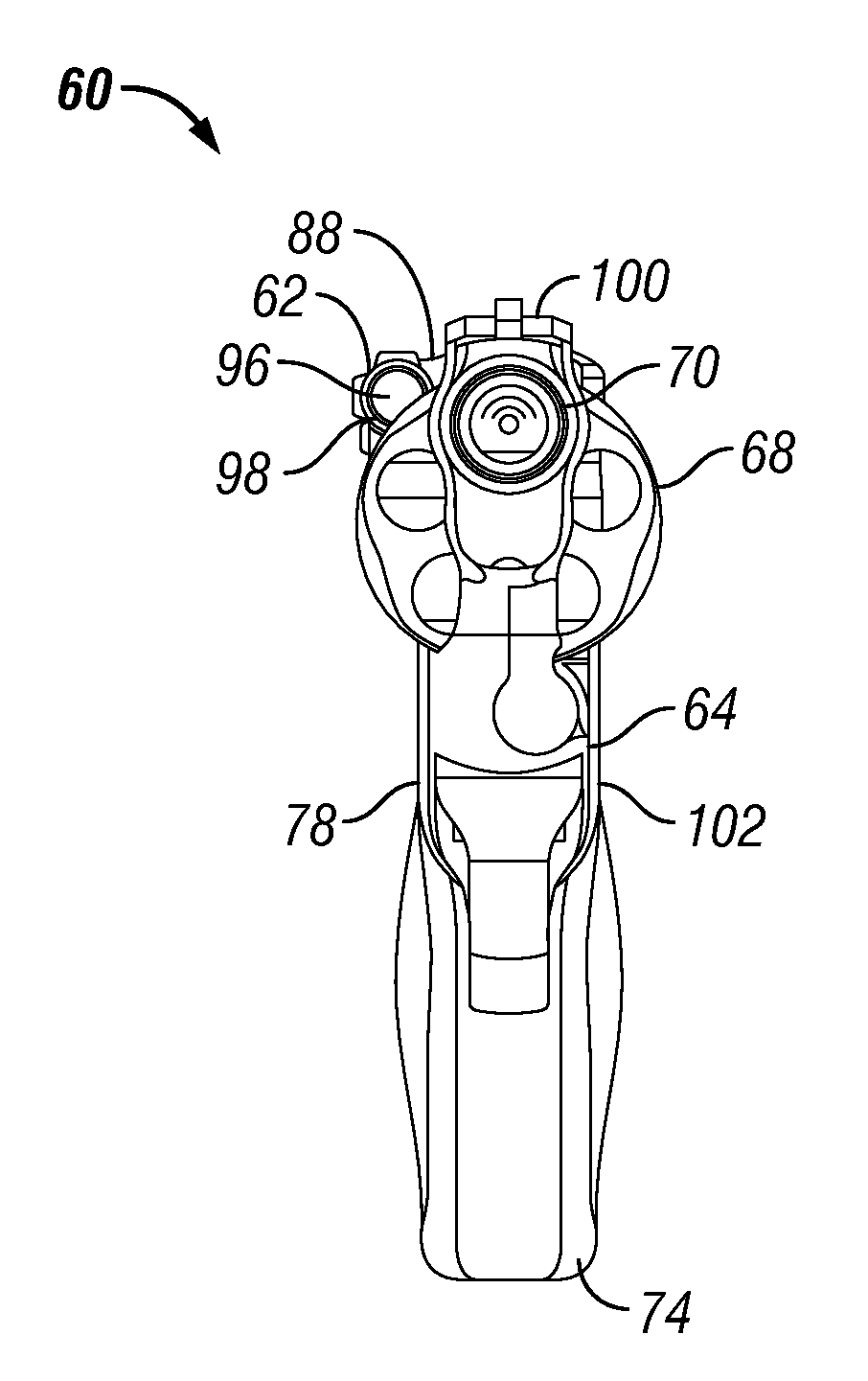

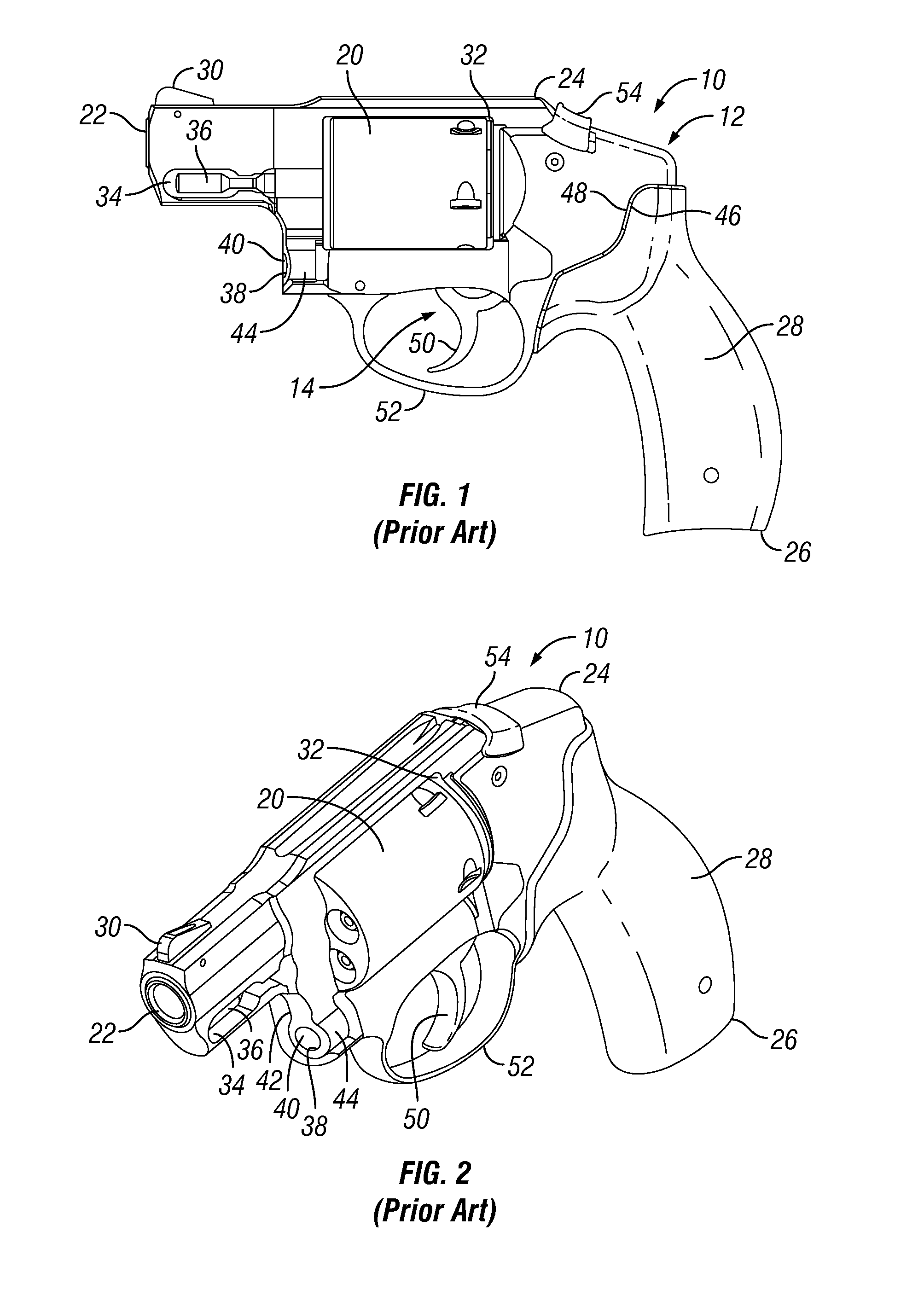

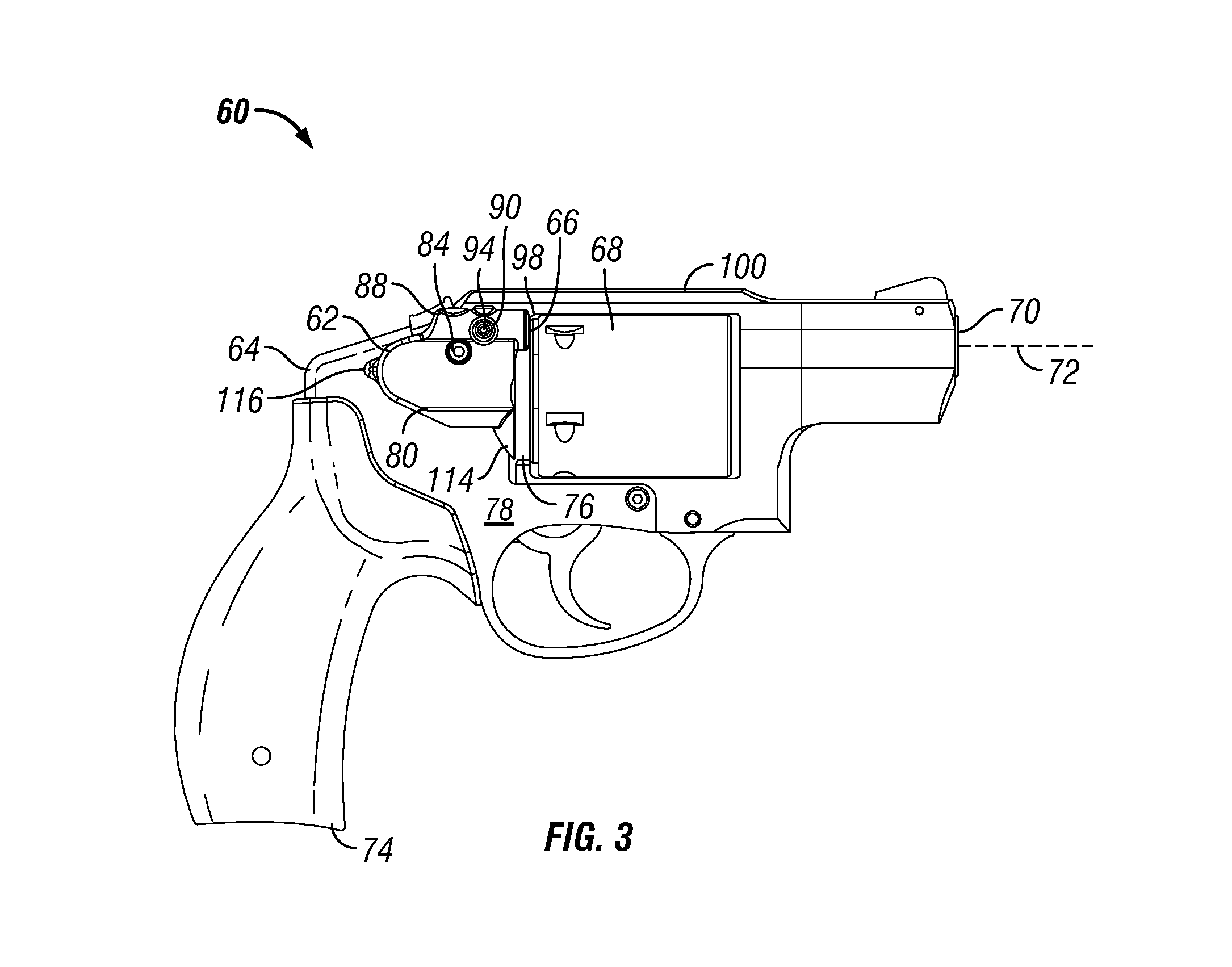

[0039]Referring to FIGS. 1 and 2, one exemplary embodiment of a firearm known in the art is shown generally at 10 and is hereinafter referred to as “firearm 10.” The firearm 10 is, preferably, a revolver that includes a frame 12, a cylinder 20, a barrel 22, and a firing mechanism 14. The operation and structure of the known firearm 10 is described in: U.S. Pat. No. 6,330,761 entitled “BLAST SHIELD APPARATUS AND METHOD OF ASSEMBLY FOR A REVOLVER”; U.S. Pat. No. 6,523,294 entitled “REVOLVER-SAFETY LOCK MECHANISM”; U.S. Pat. No. 7,059,075 entitled “CYLINDER RETAINING MECHANISM”; U.S. Pat. No. 7,254,913 entitled “REVOLVER FOR FIRING HIGH VELOCITY AMMUNITION”; U.S. Pat. No. 7,263,795 entitled “EXTRACTOR FOR A REVOLVER”; U.S. patent application Ser. No. 12 / 760,873 entitled “FIREARM HAVING NONMETALLIC COMPONENTS AND AN AMBIDEXTROUS CYLINDER RELEASE LEVER”; and U.S. patent application Ser. No. 12 / 760,927 entitled “FIREARM HAVING NONMETALLIC COMPONENTS AND AN EXTRACTOR YOKE LOCKUP”, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com