Flat heat pipe with internal supporting element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

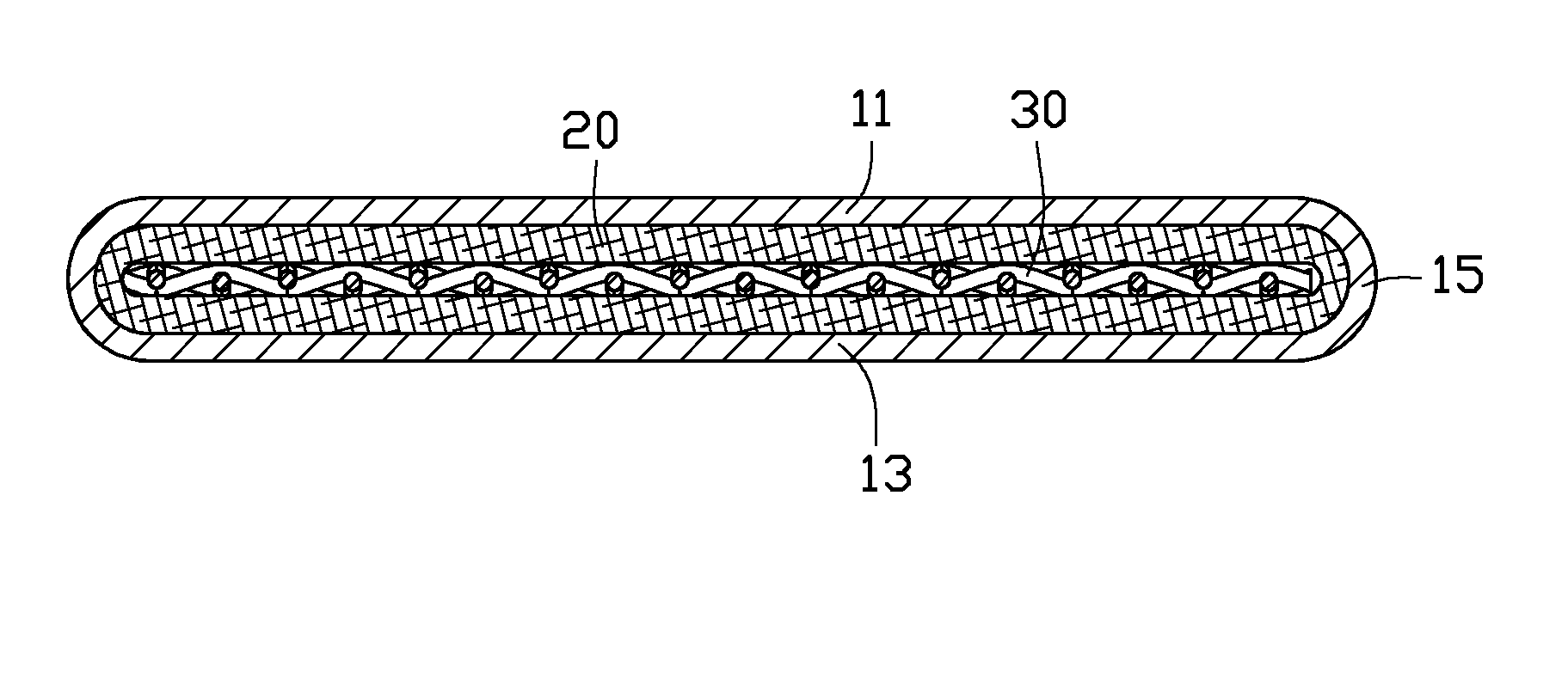

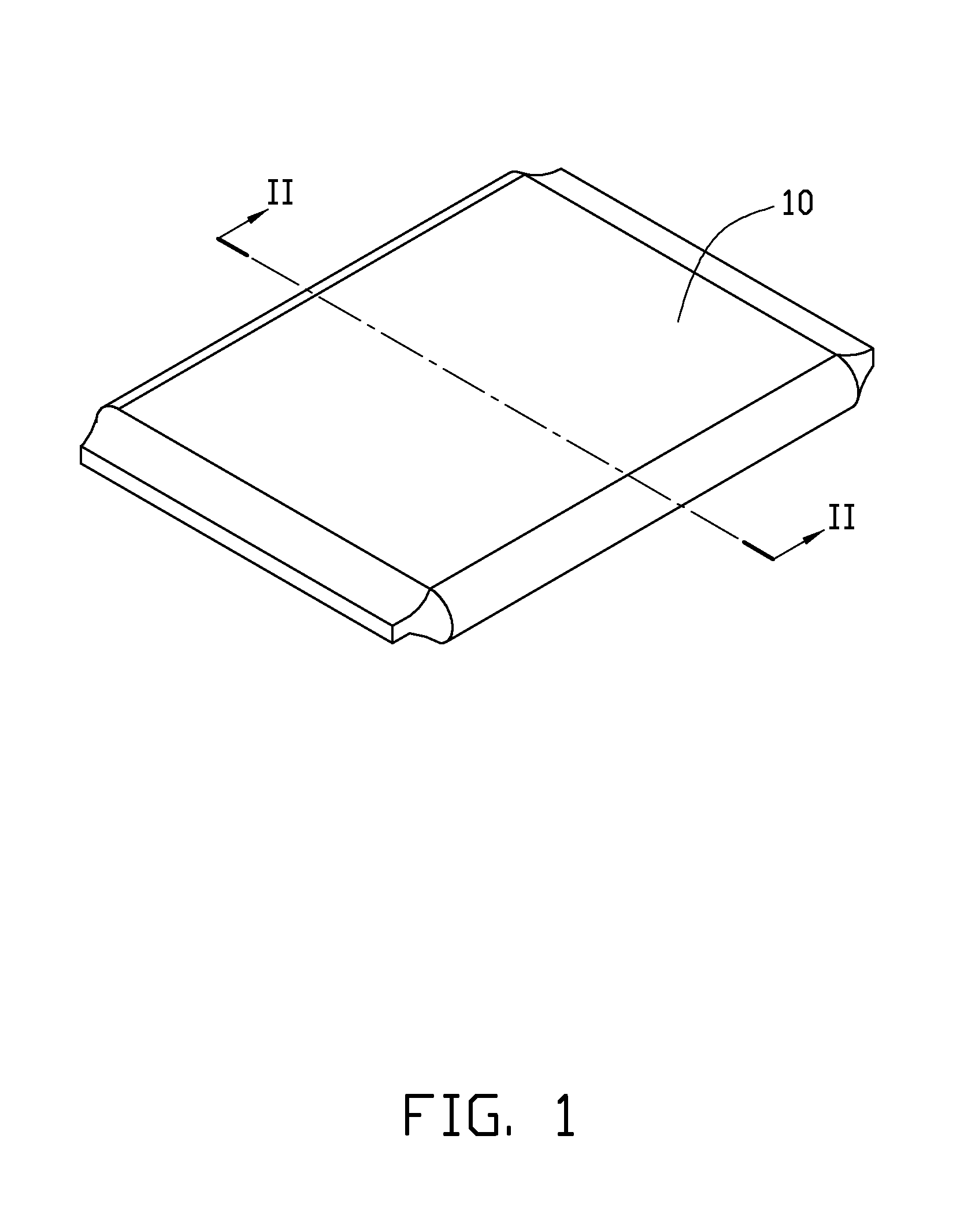

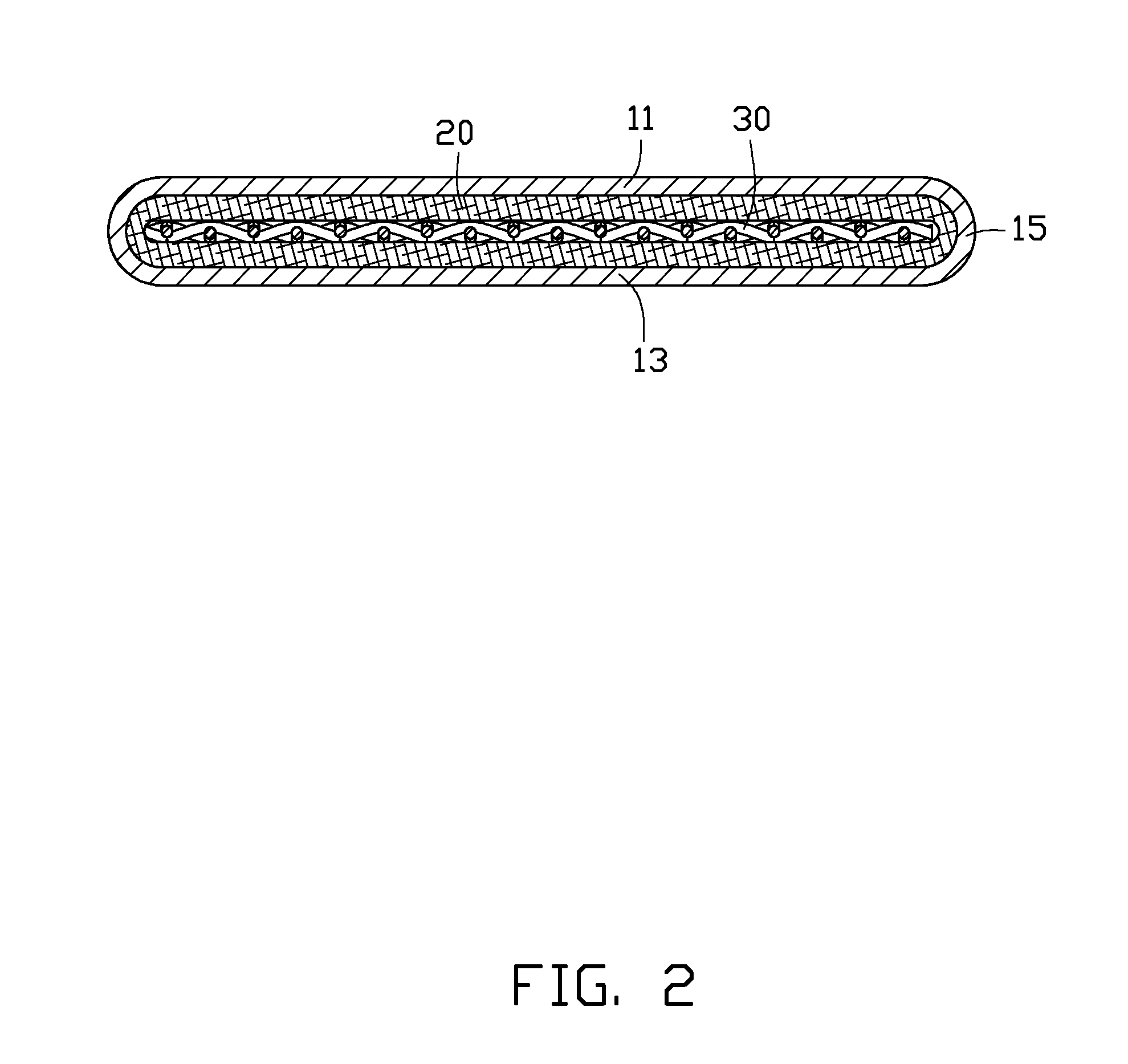

[0009]Referring to FIGS. 1-2, a flat heat pipe of the present embodiment includes a flat housing 10, a wick 20 attached to an inner surface of the housing 10, a supporting element 30 enclosed by the wick 20 and biasing the wick 20 against the housing 10, and a working fluid (not shown) contained in the housing 10.

[0010]The working fluid is water, alcohol or other material having a relatively low boiling point, which can easily change to vapor when absorbing heat from the housing 10.

[0011]The housing 10 has both ends thereof hermetically sealed, and maintains a substantial vacuum therein. In the present embodiment, the housing 10 is made from a single body of material which is hermetically crimped at both ends thereof. The housing 10 is made of a high heat conductivity material such as copper. The housing 10 includes an elongated top plate 11, an elongated bottom plate 13, and two curved connecting plates 15. The bottom plate 13 is spaced from and parallel to the top plate 11. The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com