Apparatus for premounting of locking elements to a panel

a technology for pre-mounting and locking elements, which is applied in the field of pre-mounting of locking elements to panels, can solve the problems of disadvantageous slippage of locking elements, poor installation effect of locking elements, and difficulty in proper laying of panels with latching engagement into the latching recess, etc., and achieves the effect of easy installation and inexpensive production by machin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

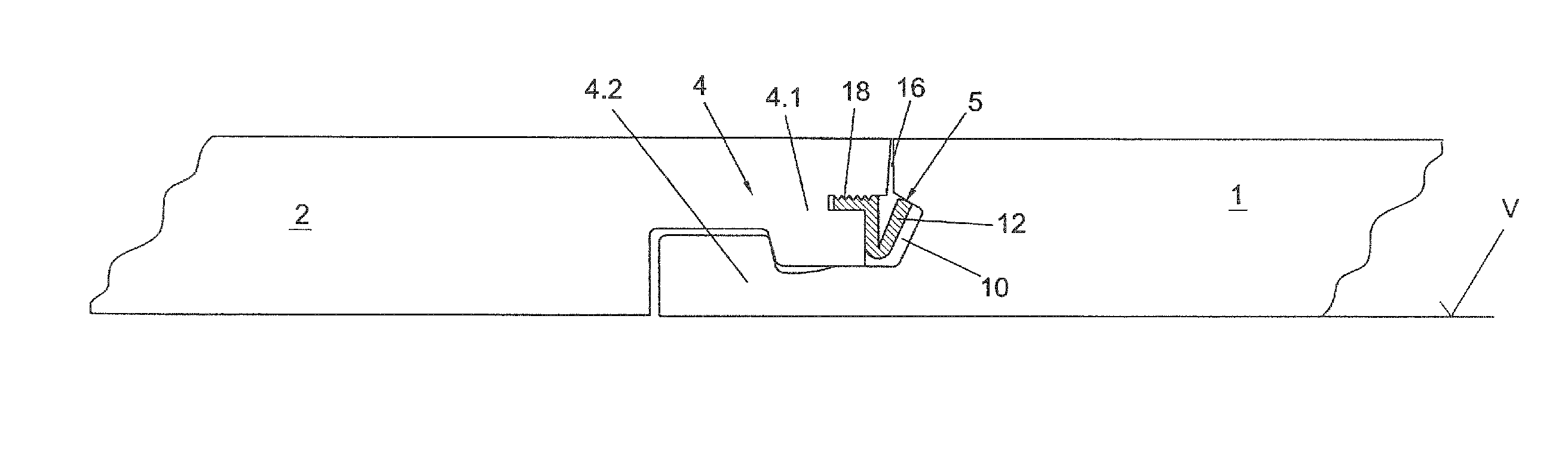

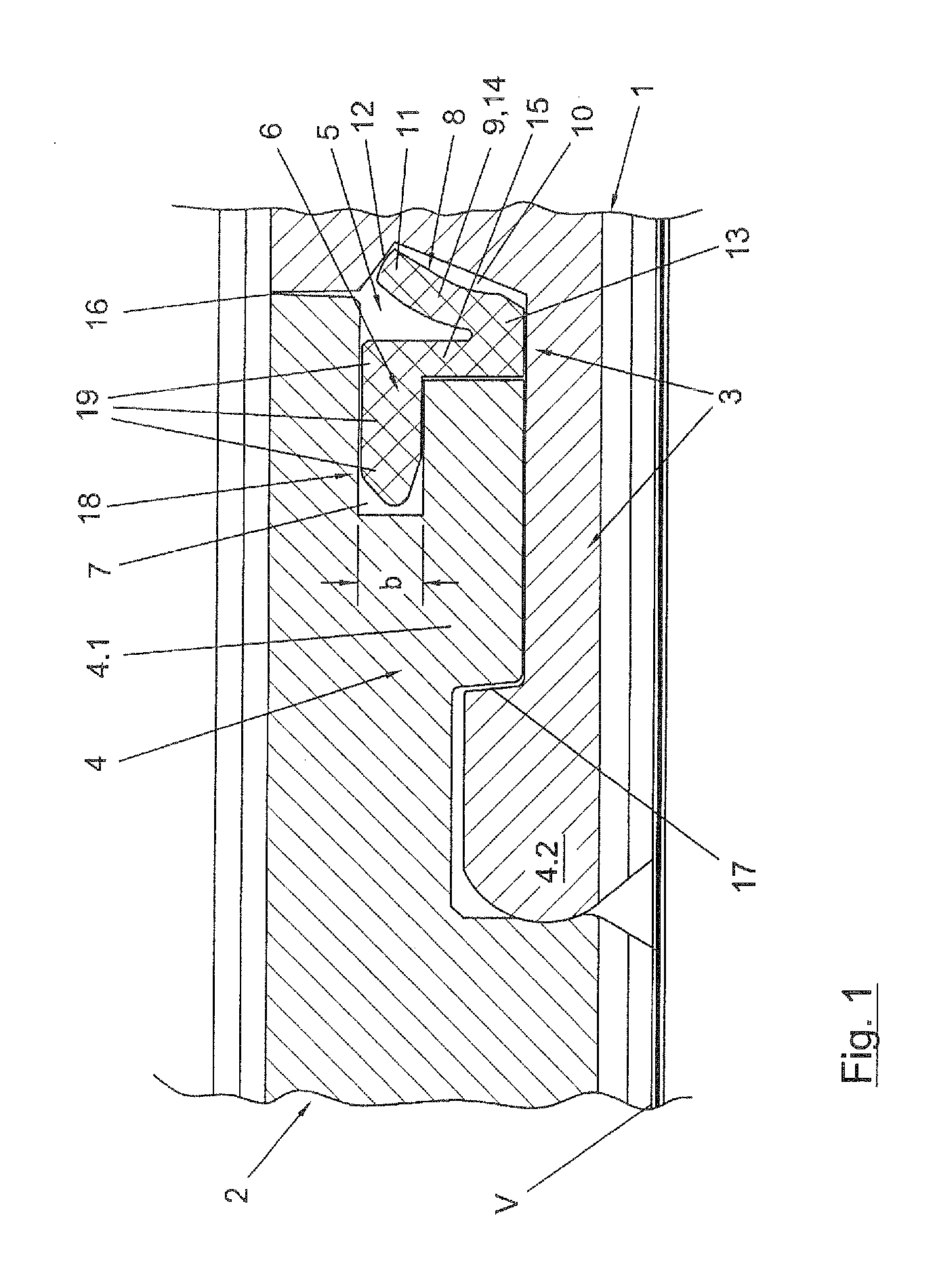

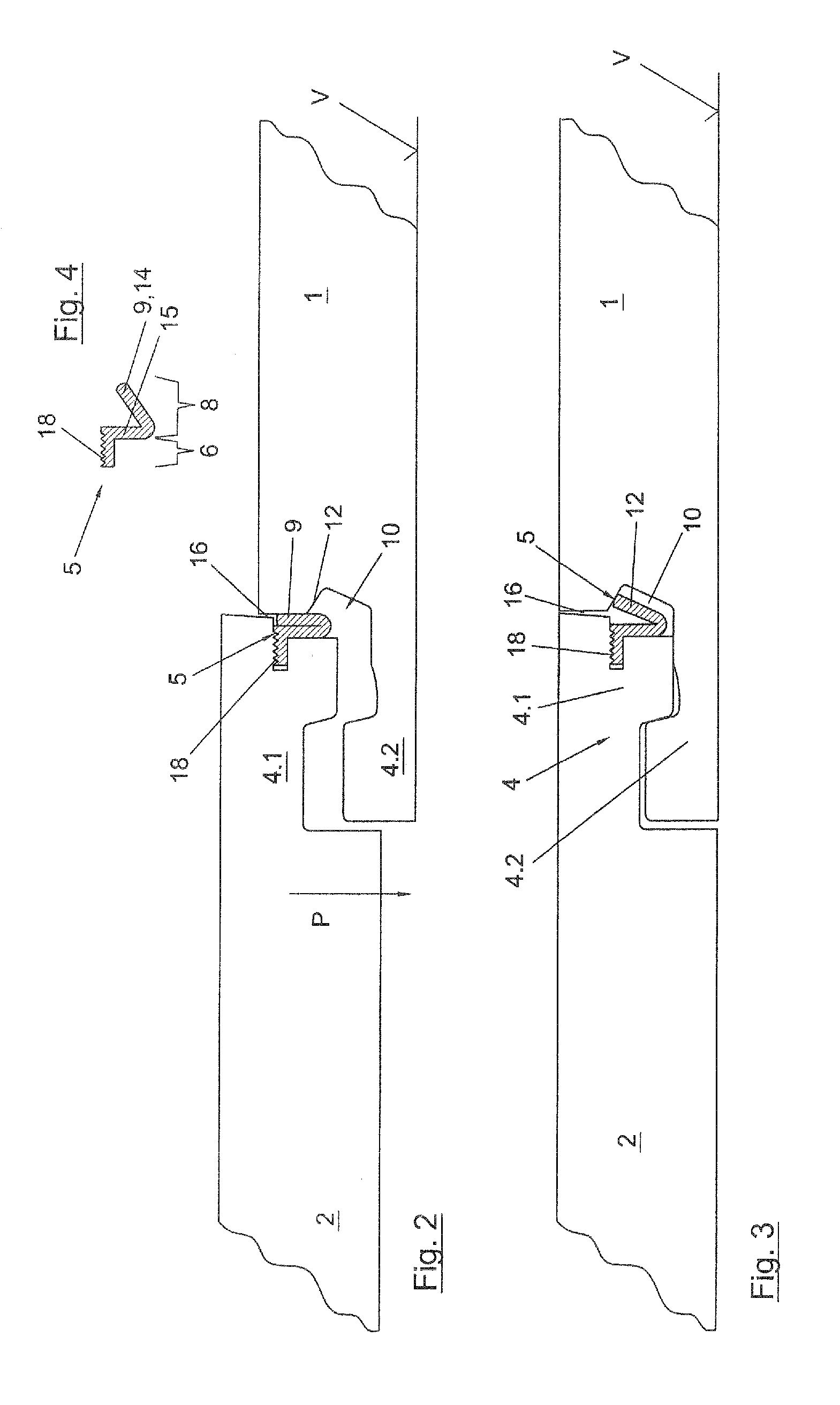

[0142]FIG. 1 shows a part of a cross-sectional view of two panels 1, 2 of a quadrangular, plate-shaped configuration, wherein the illustrated part reproduces a fixing system 3 having a locking element 5, by way of which the two panels 1, 2 are connected together and locked together at their edges or narrow sides by means of a hook connection 4 and a locking element 5 according to the invention. The hook connection 4 has two hooks 4.1, 4.2 which in the locking position are hooked into each other in such a way that the panels 1, 2 cannot be displaced horizontally relative to each other in the position which here is horizontal.

[0143]The locking element 5 is inserted with a portion in the form of an insertion portion 6 in a locking groove 7 which extends in the longitudinal direction of the edges of the panel 2, which edges extend in the plane of the drawing. The locking element 5 also has a portion in the form of a locking portion 8 with a resilient latching tongue 9 which is latched i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com