Apparatus for soil compaction

a technology of soil compaction and apparatus, applied in soil preservation, roads, roads, etc., can solve the problems of serious damage, buckling of the machine, and the full weight of the vibration tamper foot, so as to prevent the effect of buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

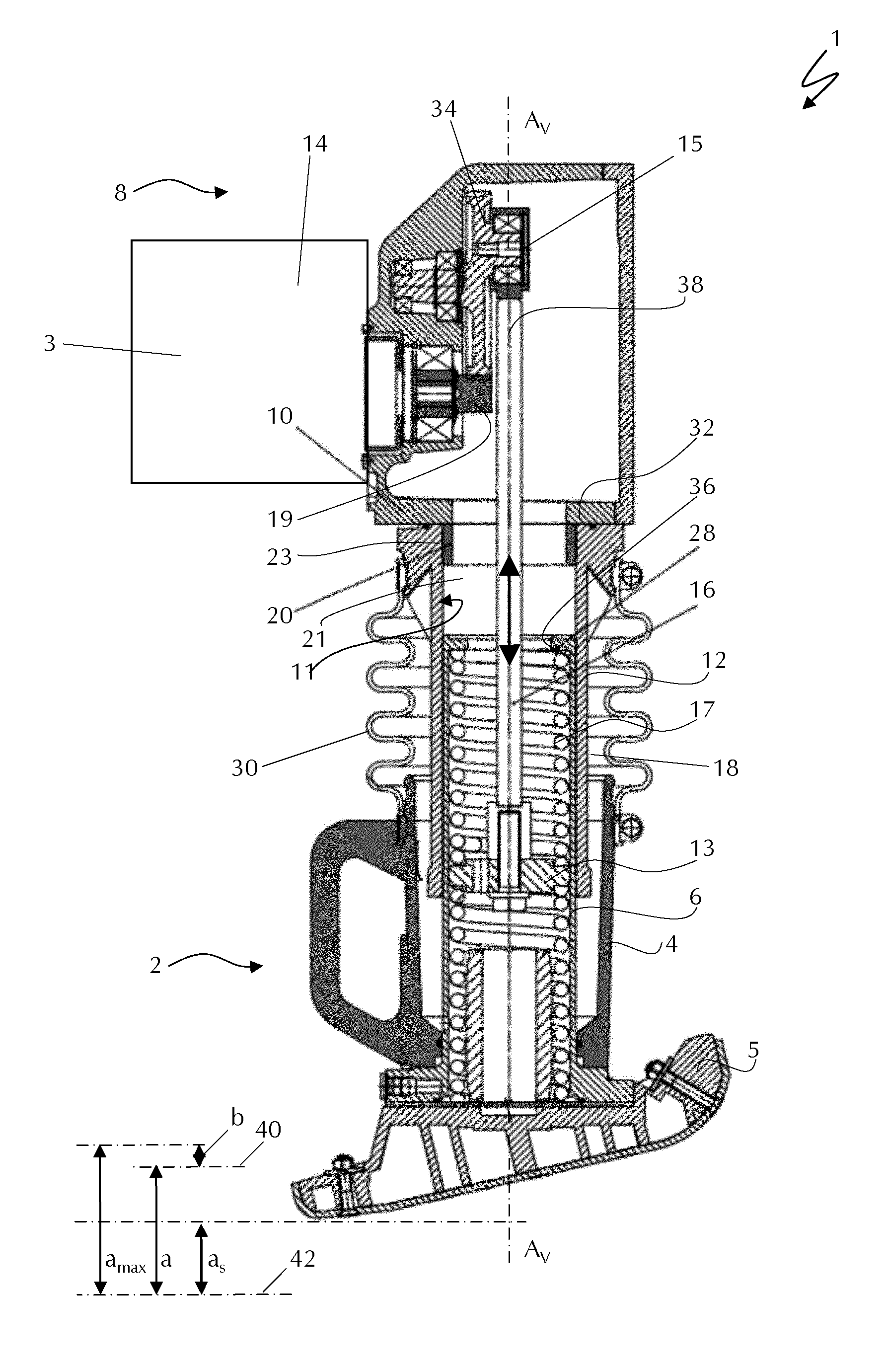

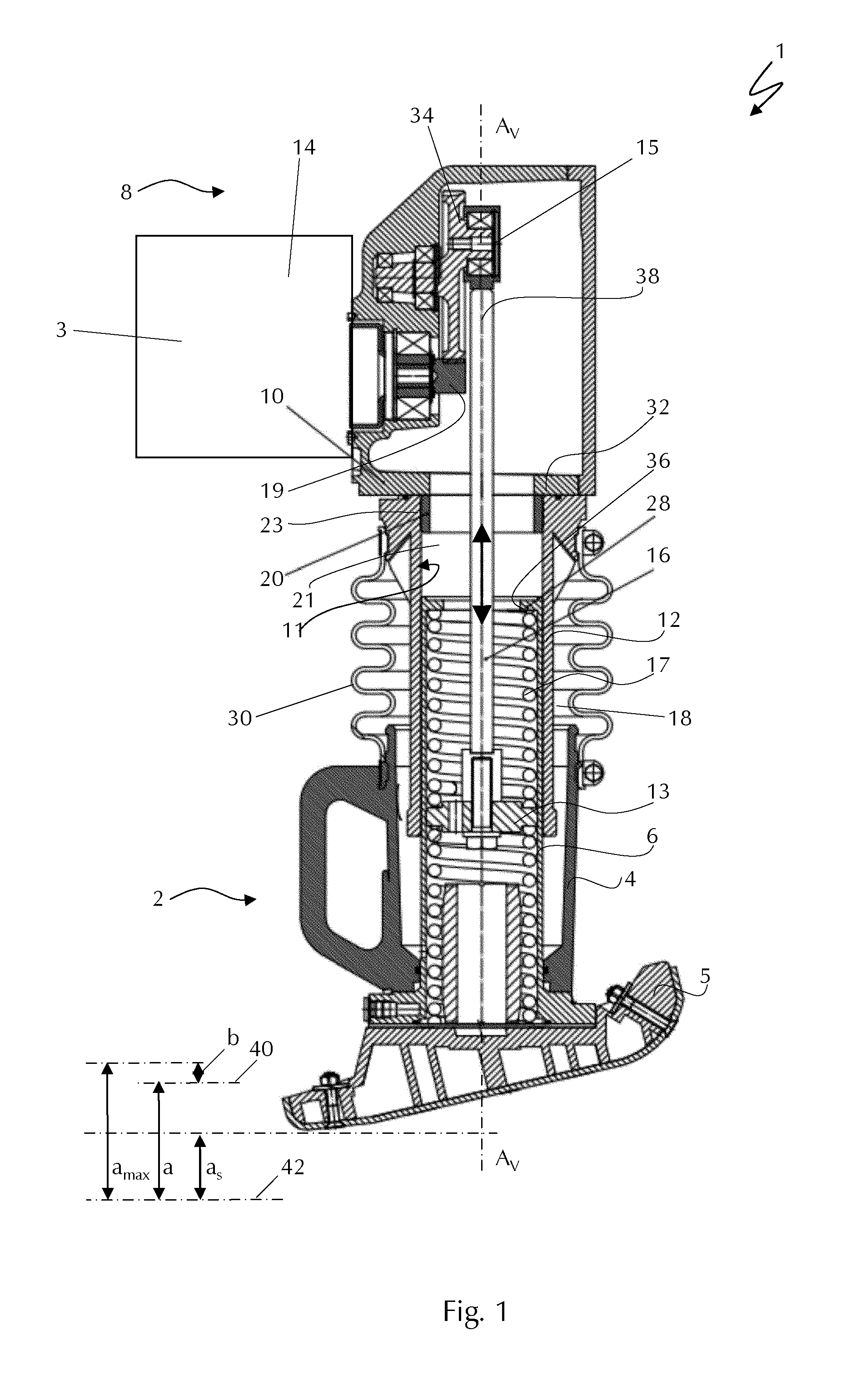

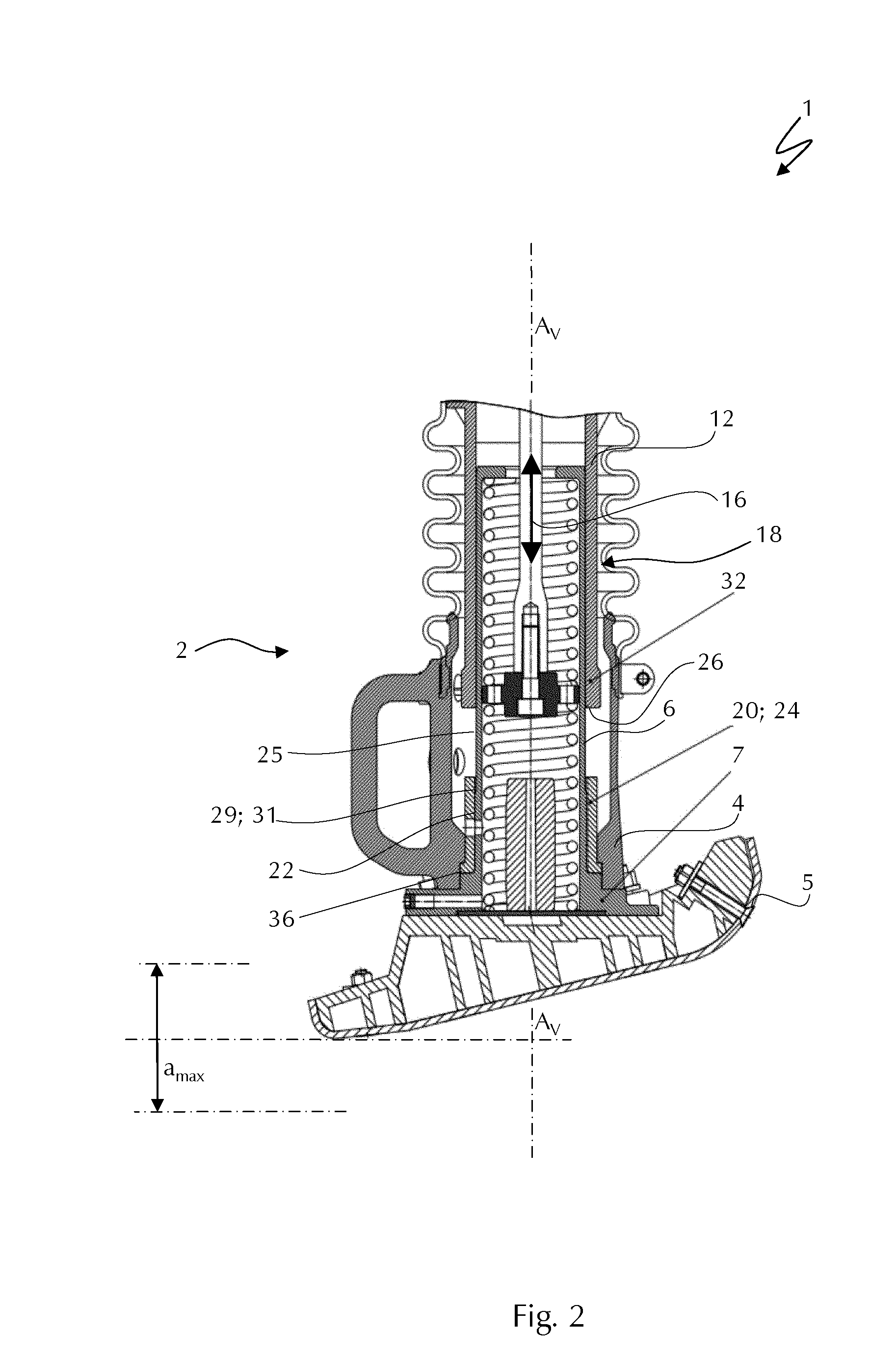

[0041]FIG. 1 shows a longitudinal sectional view through an embodiment of the apparatus for soil compaction in accordance with the present invention and especially a vibration tamper 1. The vibration tamper 1 comprises a superstructure 8 and a substructure 2 which are movable relative to one another. This movement is guided by way of an upper guide cylinder 12 which is in axial sliding connection with a bottom guide cylinder 6 coaxially to the compaction axis Av. The upper guide cylinder 12 is arranged in a stationary manner on a housing 10 of the superstructure 8, whereas the bottom guide cylinder 6 is connected in a stationary manner with a tamper plate 5 and forms a tamper foot 4. The two guide cylinders 6, 12 are movable relative to one another in such a way that a tamping movement for soil compaction can be performed within the scope of a compaction amplitude a along the compaction axis AV.

[0042]In this embodiment, the upper guide cylinder 12 forms an outside guide into which o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com