Laser confocal sensor metrology system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

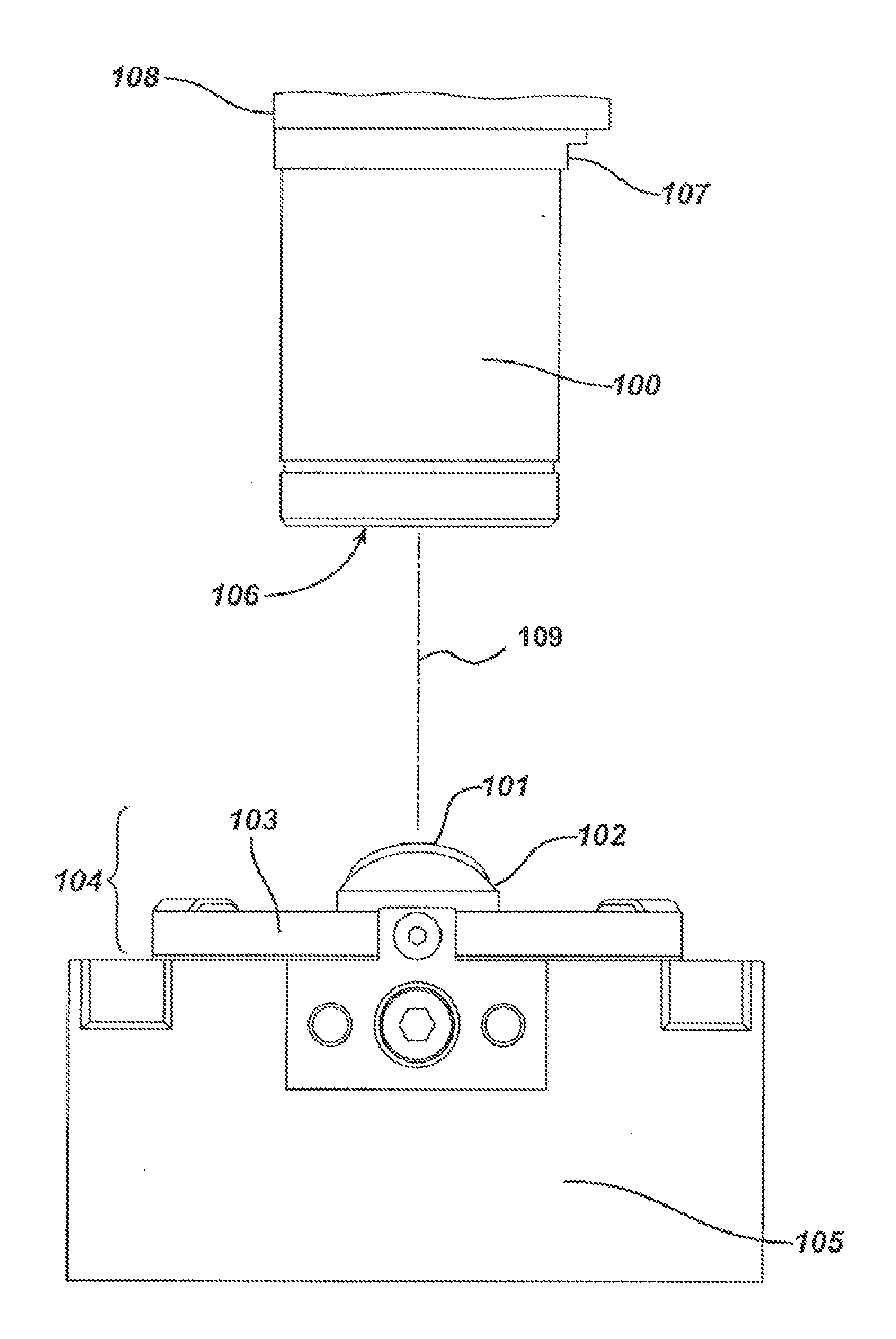

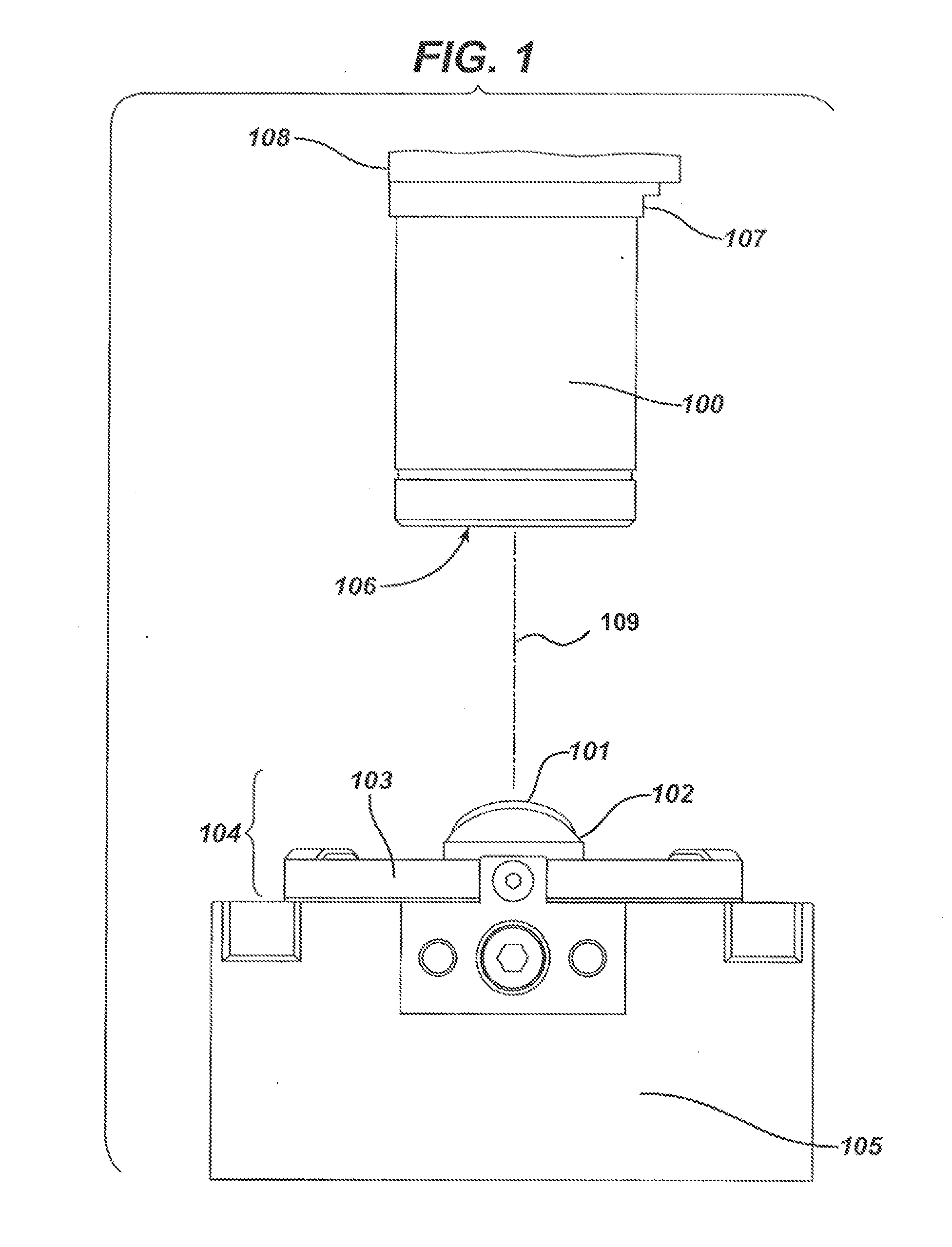

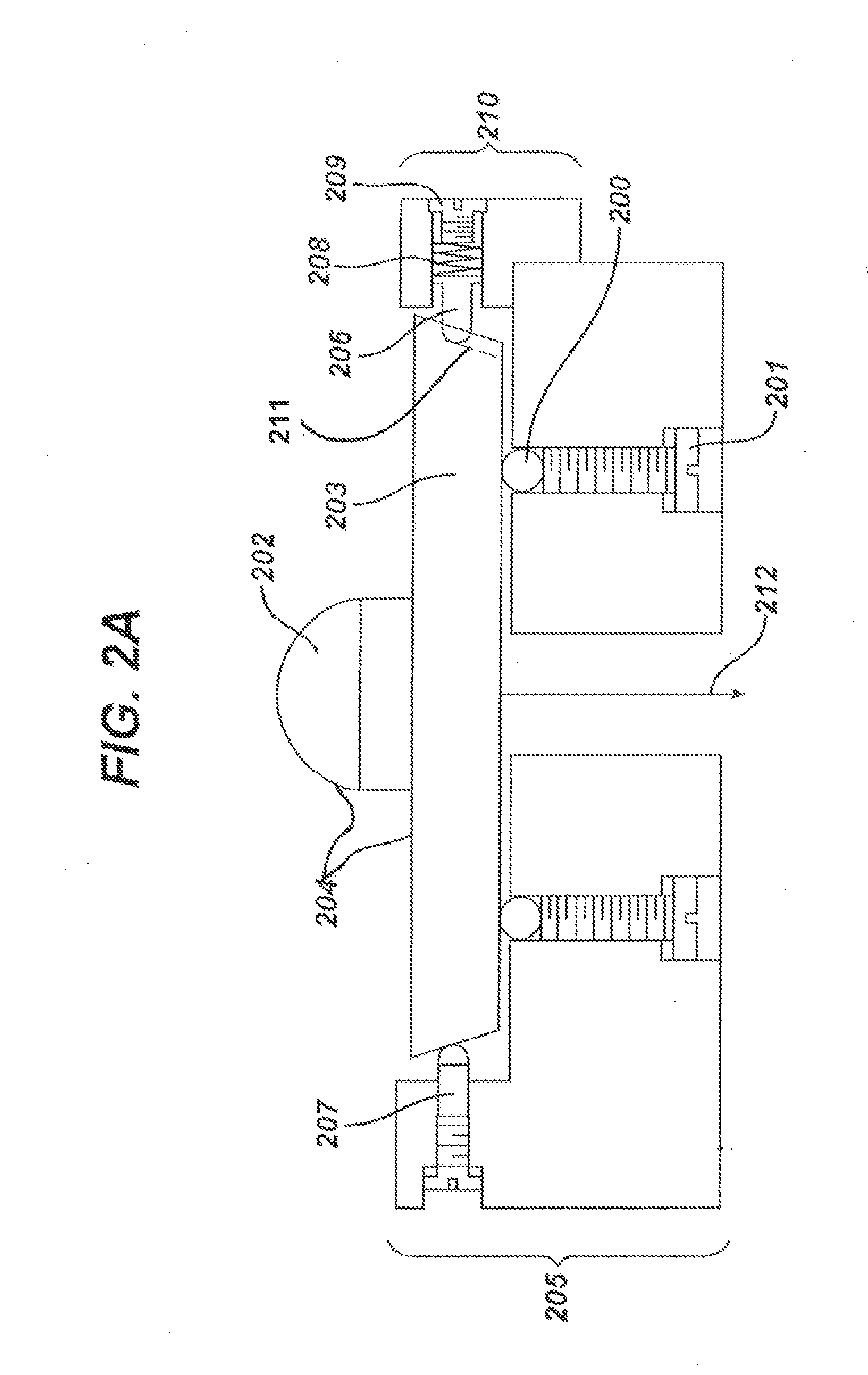

[0023]The present invention provides for methods and apparatus for measuring a thickness of one or both of a lens and Lens Precursor. In the following sections detailed descriptions of embodiments of the invention will be given. The description of both preferred and alternative embodiments though thorough are exemplary embodiments only, and it is understood to those skilled in the art that variations, modifications and alterations may be apparent. It is therefore to be understood that said exemplary embodiments do not limit the broadness of the aspects of the underlying invention. Method steps described herein are listed in a logical sequence in this discussion. However, this sequence in no way limits the order in which they may be implemented unless specifically stated. In addition, not all of the steps are required to implement the present invention and additional steps may be included in various embodiments of the present invention.

GLOSSARY

[0024]In this description and claims dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com