Apparatus for extending and retracting an armor system for defeating high energy projectiles

a technology of armor system and projectile, applied in the field of armor system, can solve the problems of affecting the system and personnel of the vehicle, affecting the safety of the vehicle, and occurrence can have a very significant detrimental effect on the system and personnel within the vehicle, and troublesome vehicles using conventional armor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

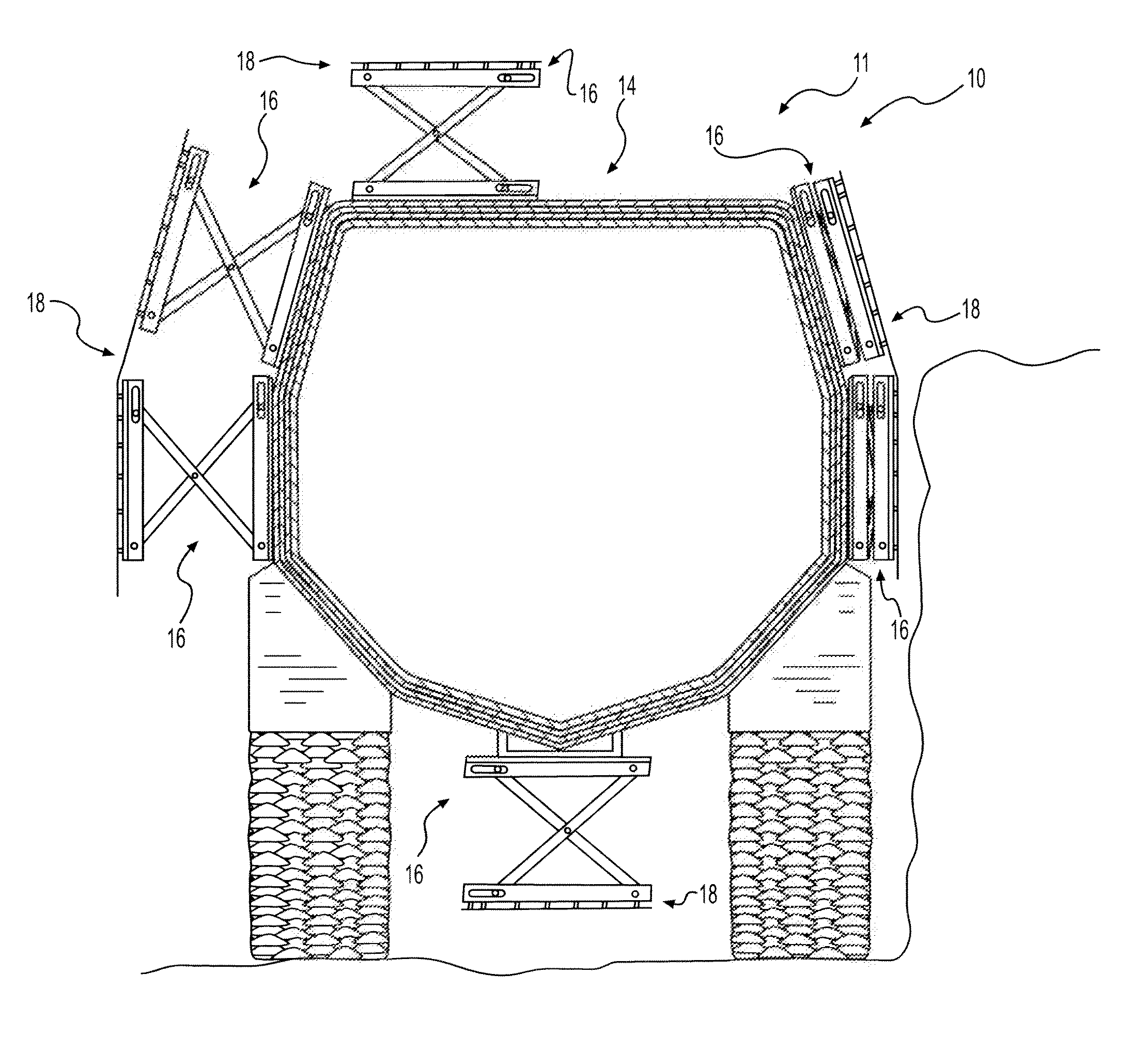

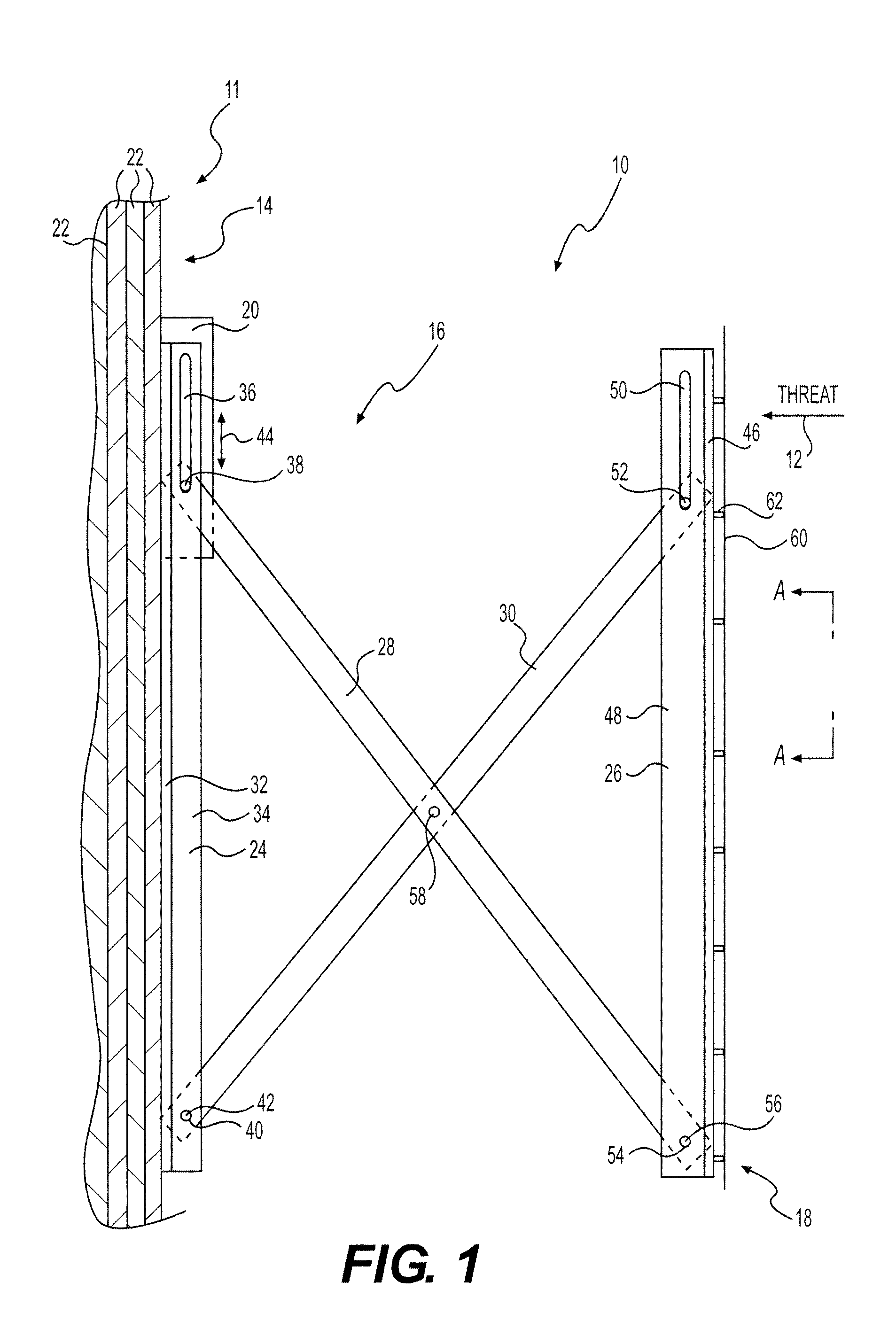

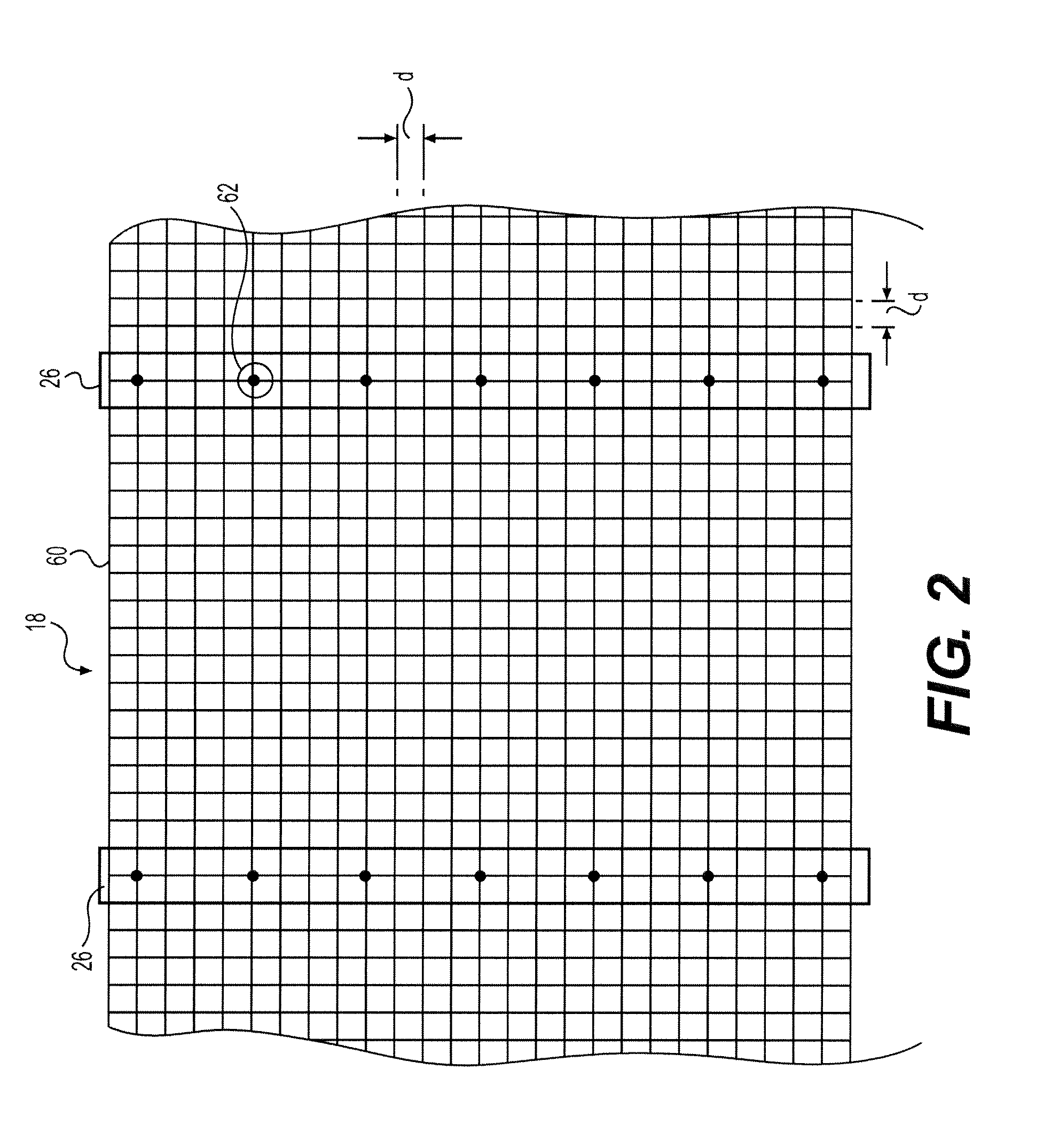

[0024]FIG. 1 illustrates an exemplary disclosed armor system 10 for protecting a vehicle 11 (shown in FIG. 4) from projectiles such as, for example, HC and Hybrid warheads. The projectiles have an expected trajectory 12 relative to vehicle 11. Armor system 10 may include an armored hull 14, at least one telescoping frame 16, at least one projectile-defeating assembly 18, and at least one jacking device 20. Telescoping frame 16 may be disposed between armored hull 14 and projectile-defeating assembly 18, and jacking device 20 may drive telescoping frame 16 to extend and retract projectile-defeating assembly 18 relative to armored hull 14.

[0025]Armored hull 14 may include a plurality of layers 22. Layers 22 may include armored layers and a vehicle hull layer, the armored layers being layered behind and / or in front of the vehicle hull layer, relative to trajectory 12. Armored hull 14 may include any number of layers 22 appropriate for defeating projectiles. Armored hull 14 may include ...

second embodiment

[0044]FIG. 5A illustrates an exemplary disclosed armor system for protecting a vehicle 111 (shown in FIG. 6). The elements of an armor system 110 may be generally similar to armor system 10. Armor system 110 may include an armored hull 114 that includes a plurality of layers 122, at least one telescoping frame 116, at least one projectile-defeating assembly 118, and at least one jacking device 120.

[0045]Each telescoping frame 116 may include a first attaching member 124 having an aperture, a second attaching member 126 having an aperture, a first cross member 128, a second cross member 130, and a support member 132. First attaching member 124 and second attaching member 126 may attach telescoping frame 116 to armored hull 114, and first and second cross members 128 and 130 may be attached to support member 132.

[0046]First cross member 128 may be a movable cross member including a first attaching member 134 having an aperture, a second attaching member 136 having an aperture, a first...

third embodiment

[0054]FIG. 7A illustrates an exemplary disclosed armor system for protecting a vehicle. The elements of an armor system 210 may be generally similar to armor system 10. Armor system 210 may include a vehicle armored hull 214 including a plurality of layers 222 similar to layers 22, at least one telescoping frame 216, at least one projectile-defeating assembly 218 that may be similar to projectile-defeating assembly 18, and at least one jacking device 220.

[0055]Each telescoping frame 216 may include an attaching member 224 having an aperture, a cross member 228, and a support member 232 having an aperture. Attaching member 224 may attach telescoping frame 216 to armored hull 214, and cross member 228 may attach support member 232 to attaching member 224. Support member 232 may support projectile-defeating assembly 218.

[0056]Cross member 228 may be a movable cross member including a first support member 238 having an aperture on each of its end portions and a second support member 240...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com