Heat pipe with a radial flow shunt design

a radial flow and heat pipe technology, applied in the field of heat pipes, can solve the problems of heat source not being able to efficiently transfer heat subject to phase change, and the structure of regular composite wicks is not designed for multi-heat-source applications, so as to enhance the working fluid flow speed and phase cycling, and avoid dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

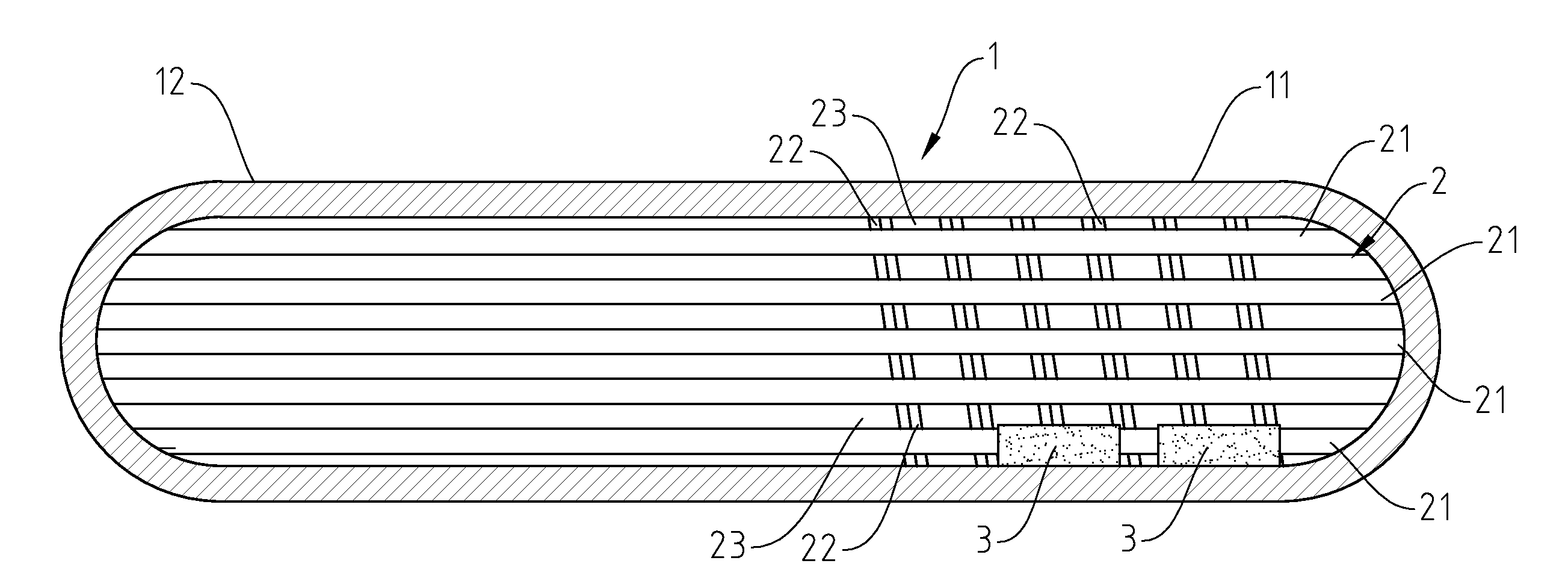

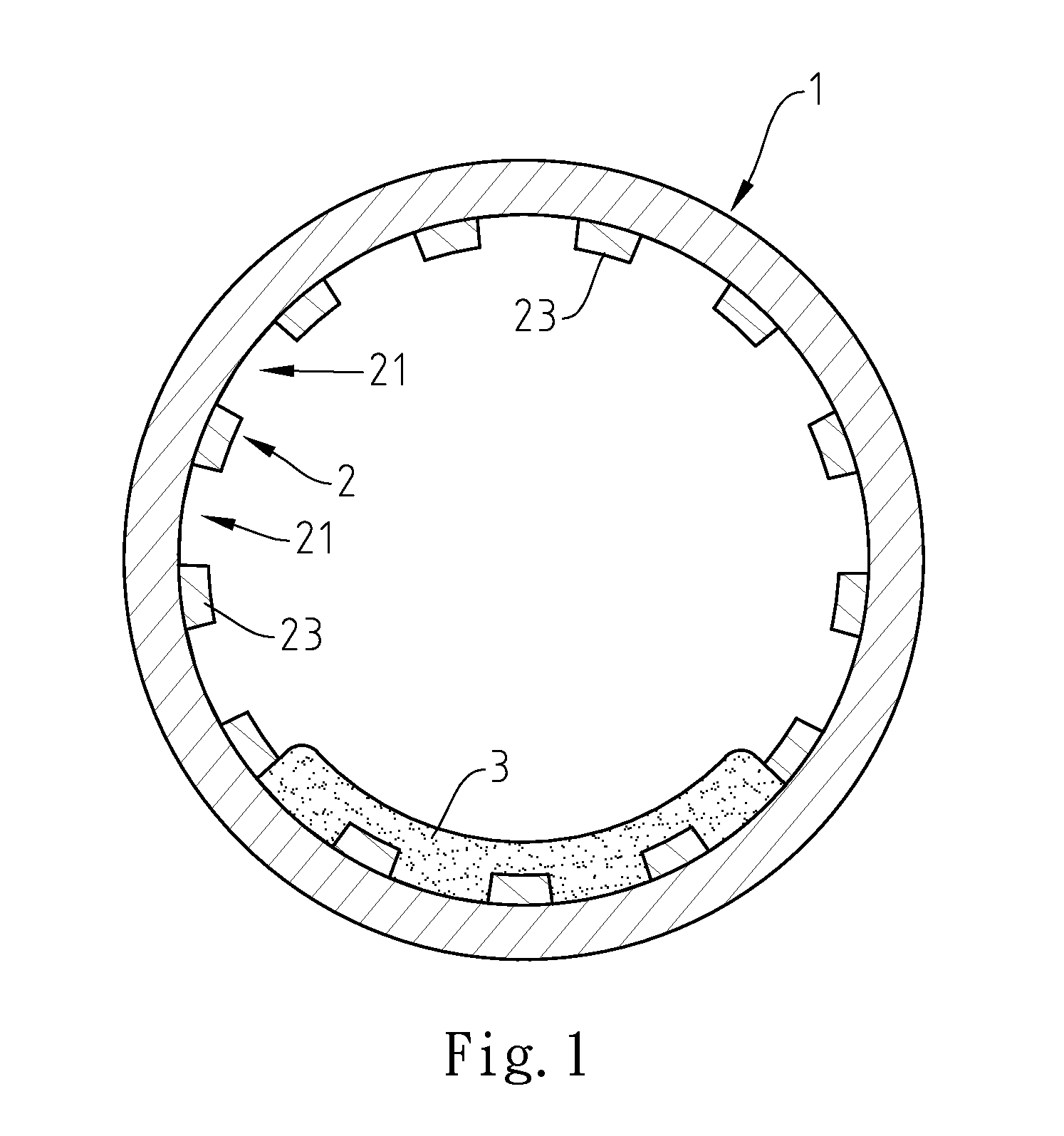

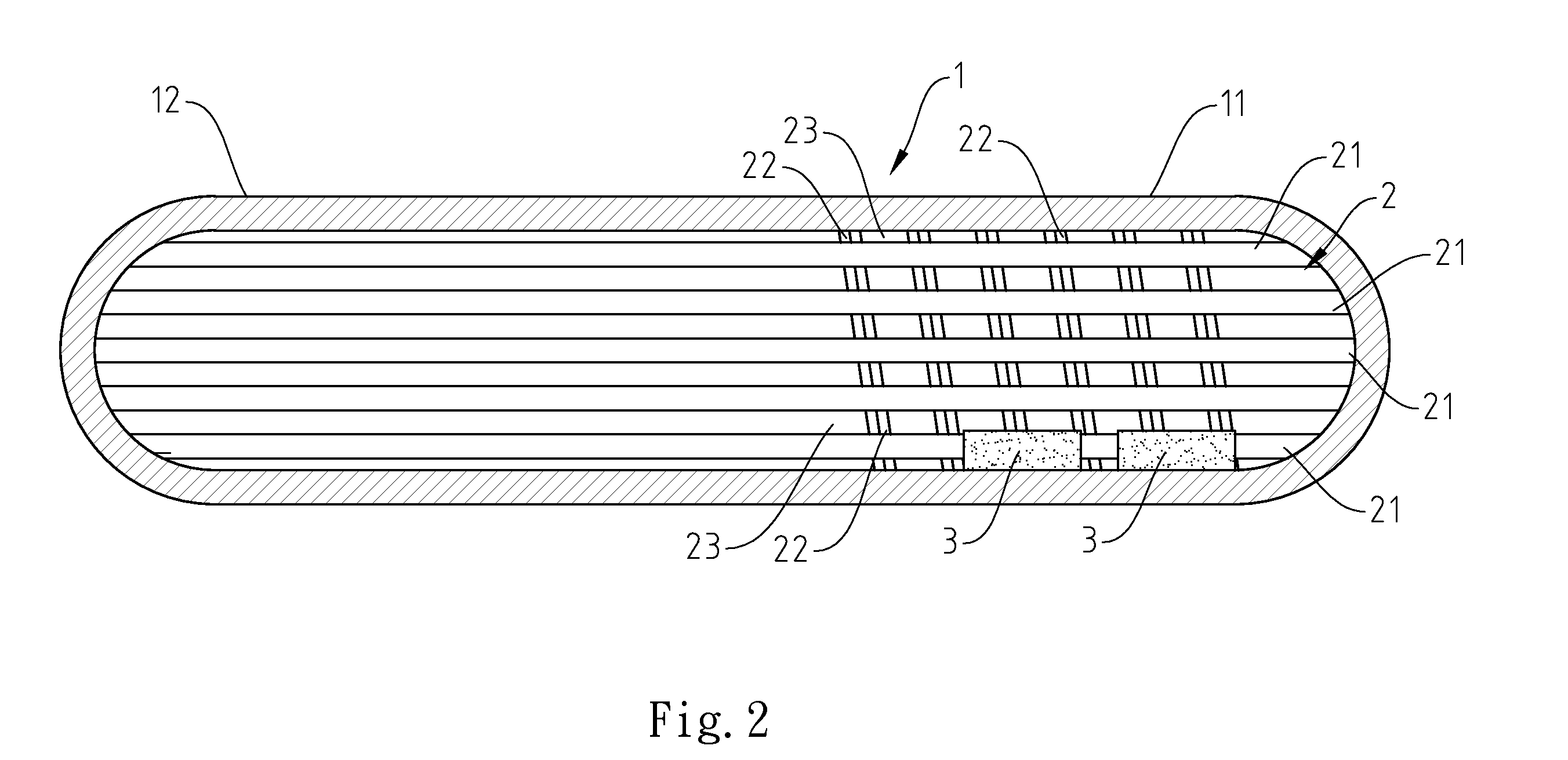

[0014]Referring to FIGS. 1 and 2, a heat pipe in accordance with a first embodiment of the present invention is shown comprising a pipe body 1, a first wick structure 2 located on the surface of the inside wall of the pipe body 1, and a second wick structure 3 formed on a part of the surface of the first wick structure 2 by a sintering technique.

[0015]The pipe body 1 comprises opposing evaporation segment 11 and condensing segment 12, and has a working fluid filled therein.

[0016]The first wick structure 2 comprises a plurality of ribs 23 axially extending through the evaporation segment 11 and the condensing segment 12, a channel 21 defined between each two adjacent ribs 23, and a plurality of spiral grooves 22 arranged in the evaporation segment 11 and transversely cut through the ribs 23 to keep the channels 21 in communication with one another. Thus, the channels 21 are intersected with the spiral grooves 22, forming a lattice pattern. The spiral grooves 22 can be formed by means...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com