Solder bath and method of heating solder contained in the solder bath

a technology of solder bath and solder bath, which is applied in the direction of soldering apparatus, lighting and heating apparatus, and immersion heating arrangements, etc., can solve the problems of solder bridge, soldering defect, and soldering bridge, and achieve easy partial variation in temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The inventors have found that it is possible to heat the solder contained in the solder bath main body as evenly as possible and to melt the solder by followings:

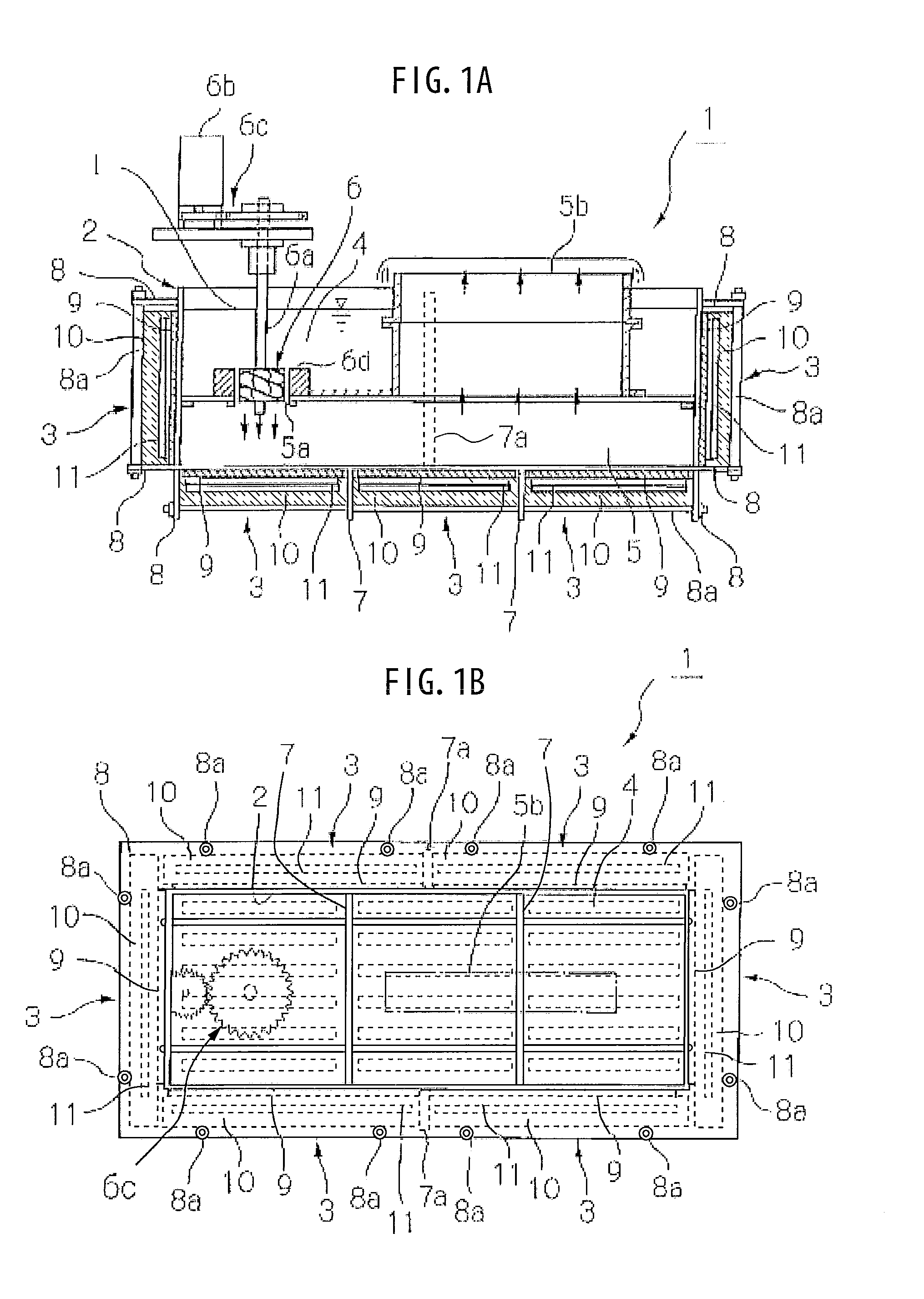

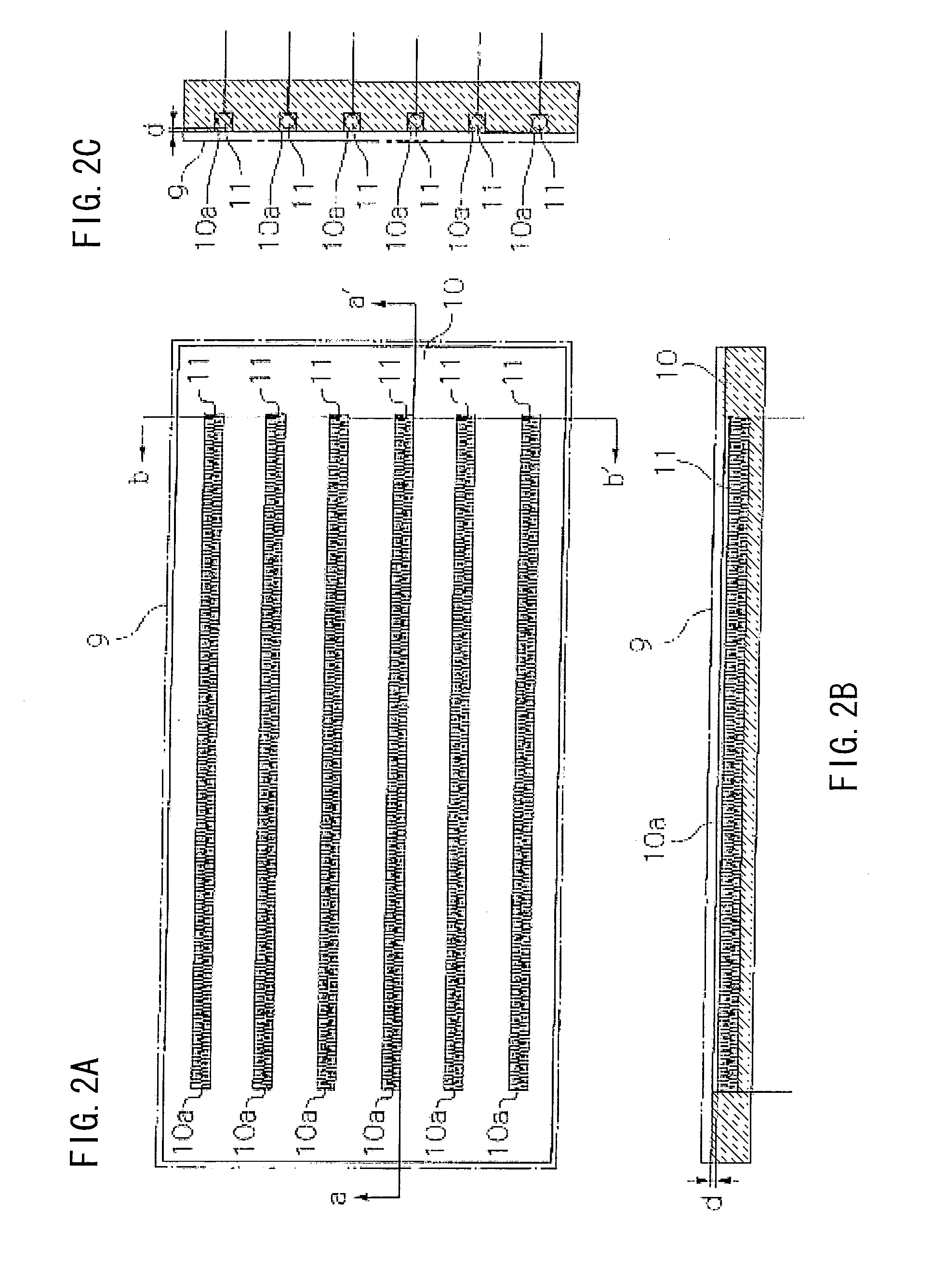

[0029](a) A heating member does not directly heat the solder bath main body but heats the thermal diffusion member made of stainless steel and mounted on the outer surfaces of the bottom and sides of the solder bath main body and the thermal diffusion member heats the solder bath main body through thermal diffusion from the thermal diffusion member; and

[0030](b) A heating resistive element, which is buried in the porous heat insulator that is mounted on and attached to the thermal diffusion member and which is away from the thermal diffusion member heats the thermal diffusion member. They then invent embodiments of the present invention.

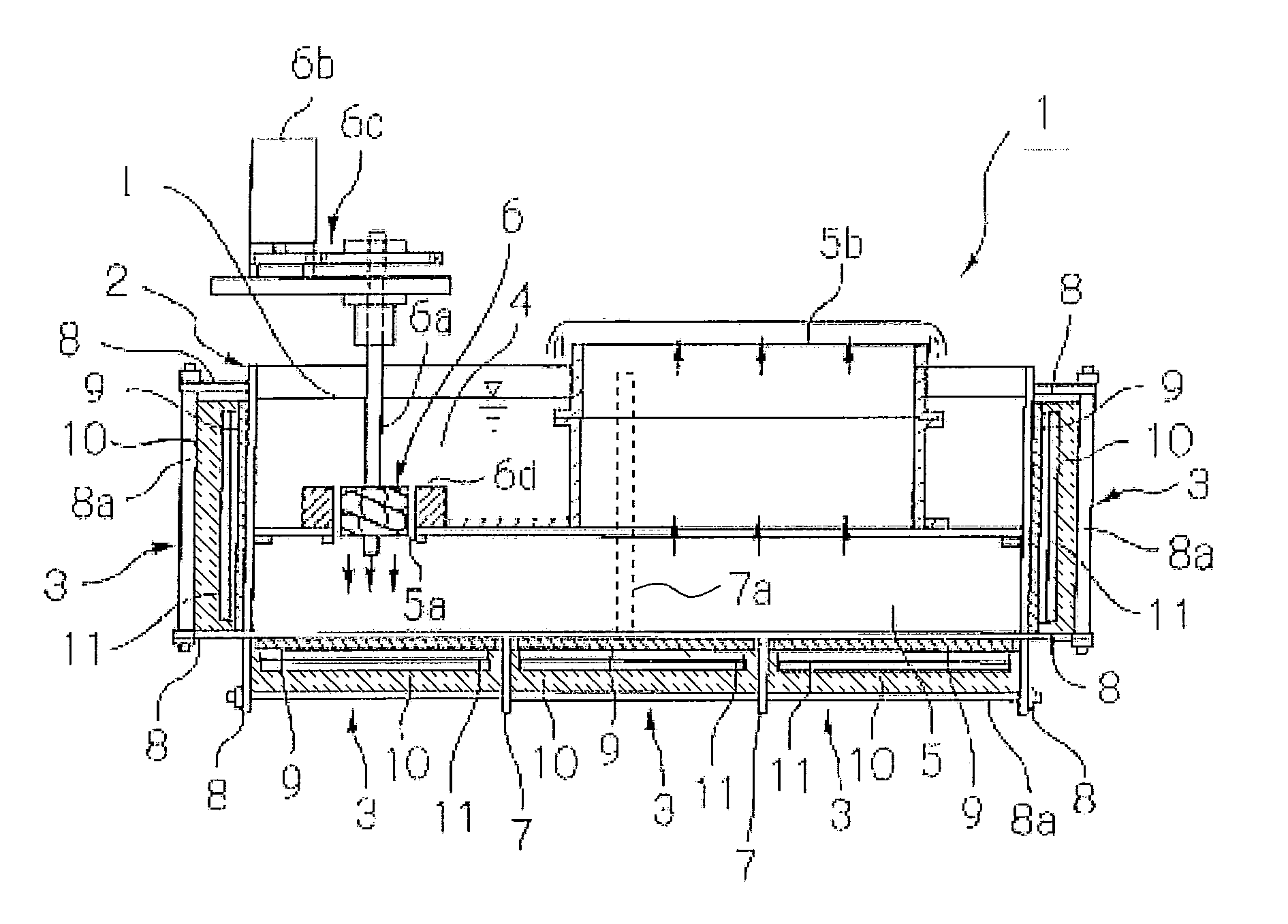

[0031]The following will describe the embodiments of the present invention with reference to the drawings. FIGS. 1A and 1B show a configuration of an embodiment of a solder bath 1 acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com