Printer

a printing machine and paper cutting technology, applied in printing, metal working equipment, other printing equipment, etc., can solve the problem of reducing the force of the press member to press the cut-off paper stacked in the paper stacking portion, and achieve the effect of reducing the maximum load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

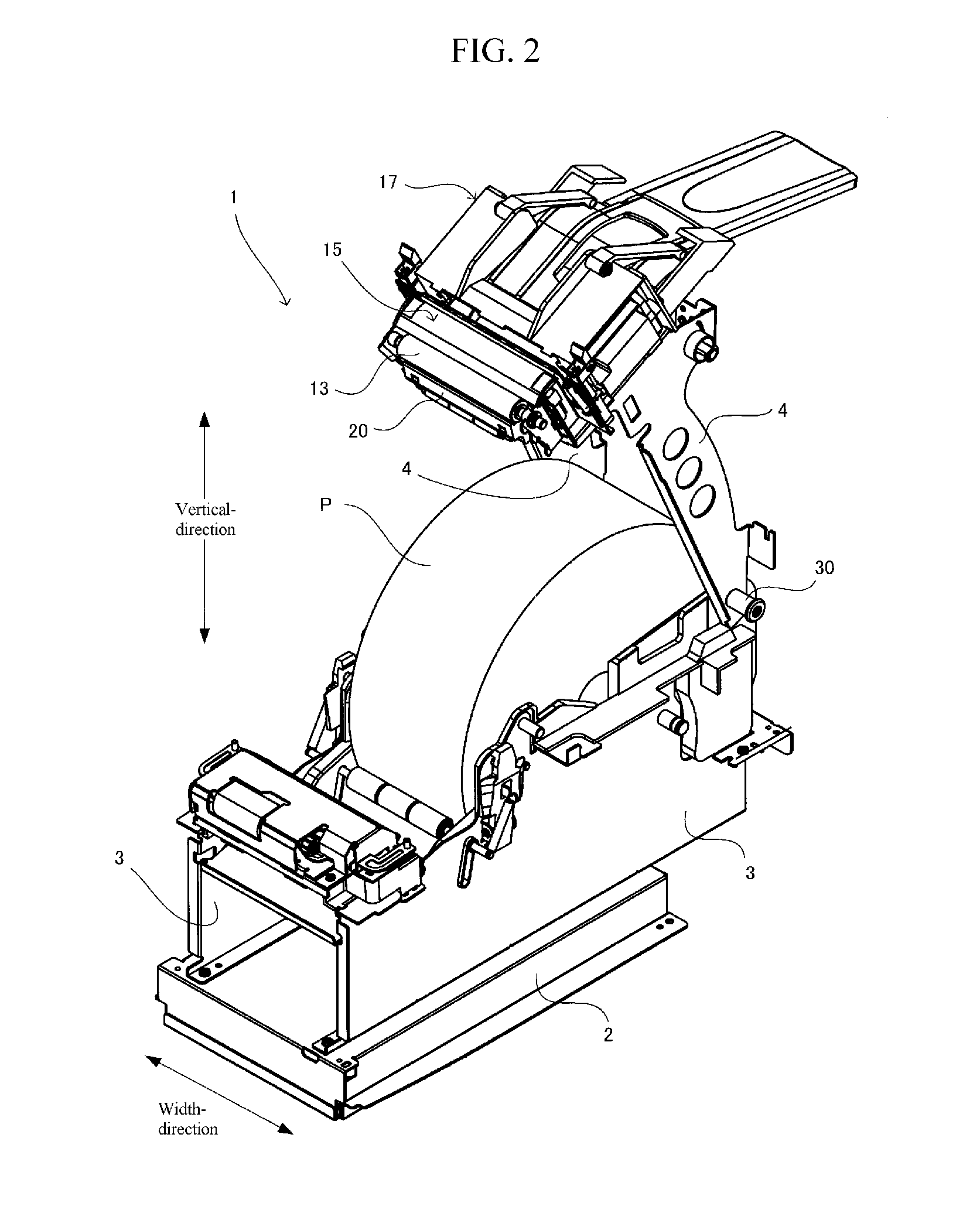

[0034]Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

[0035]A printer as an embodiment of the present invention may be a thermal printer adapted to draw out paper from a paper roll which is made by rolling an elongated heat sensitive paper and the like in a roll shape, perform printing on the paper, and cut a printed part of the paper.

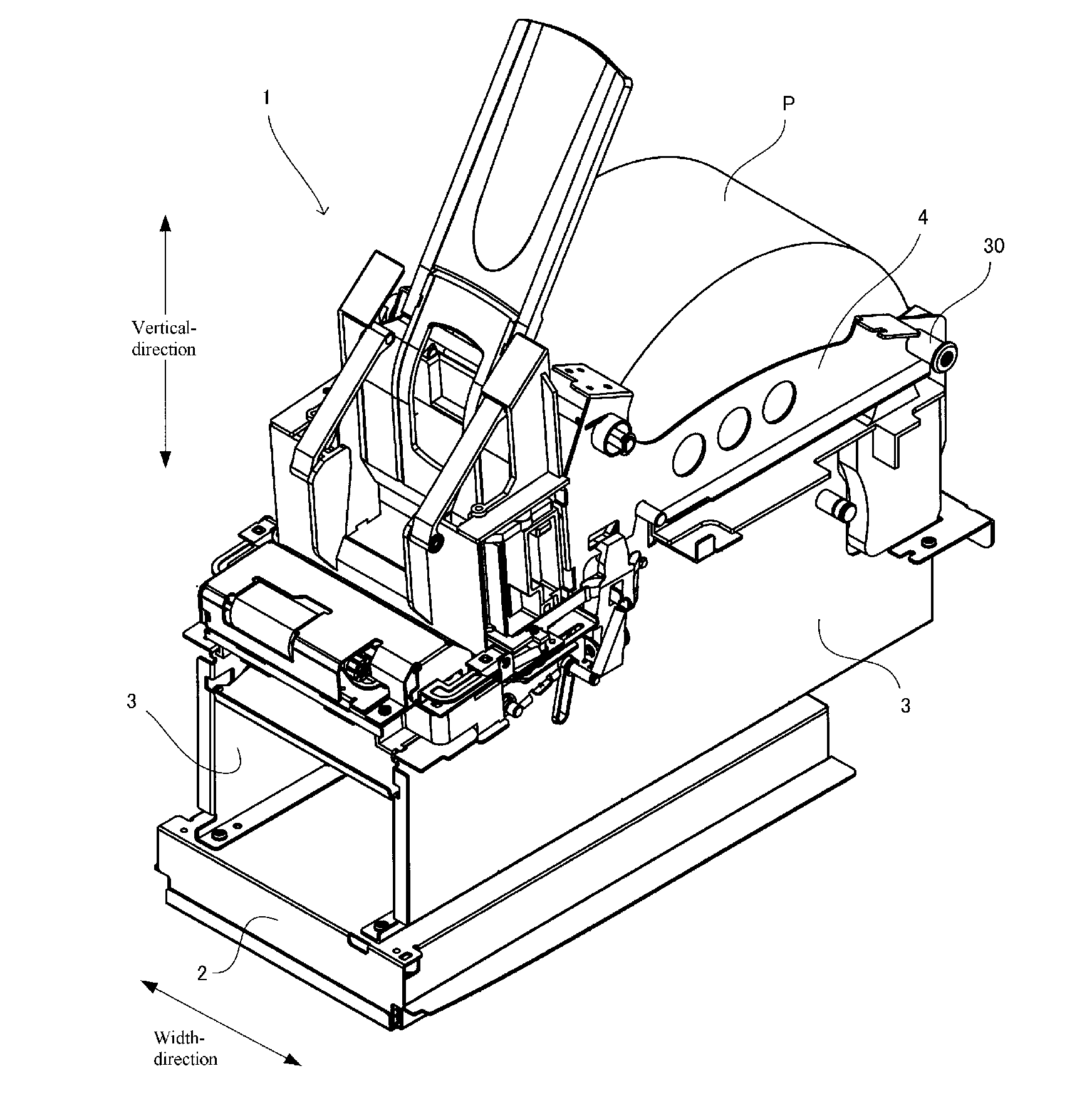

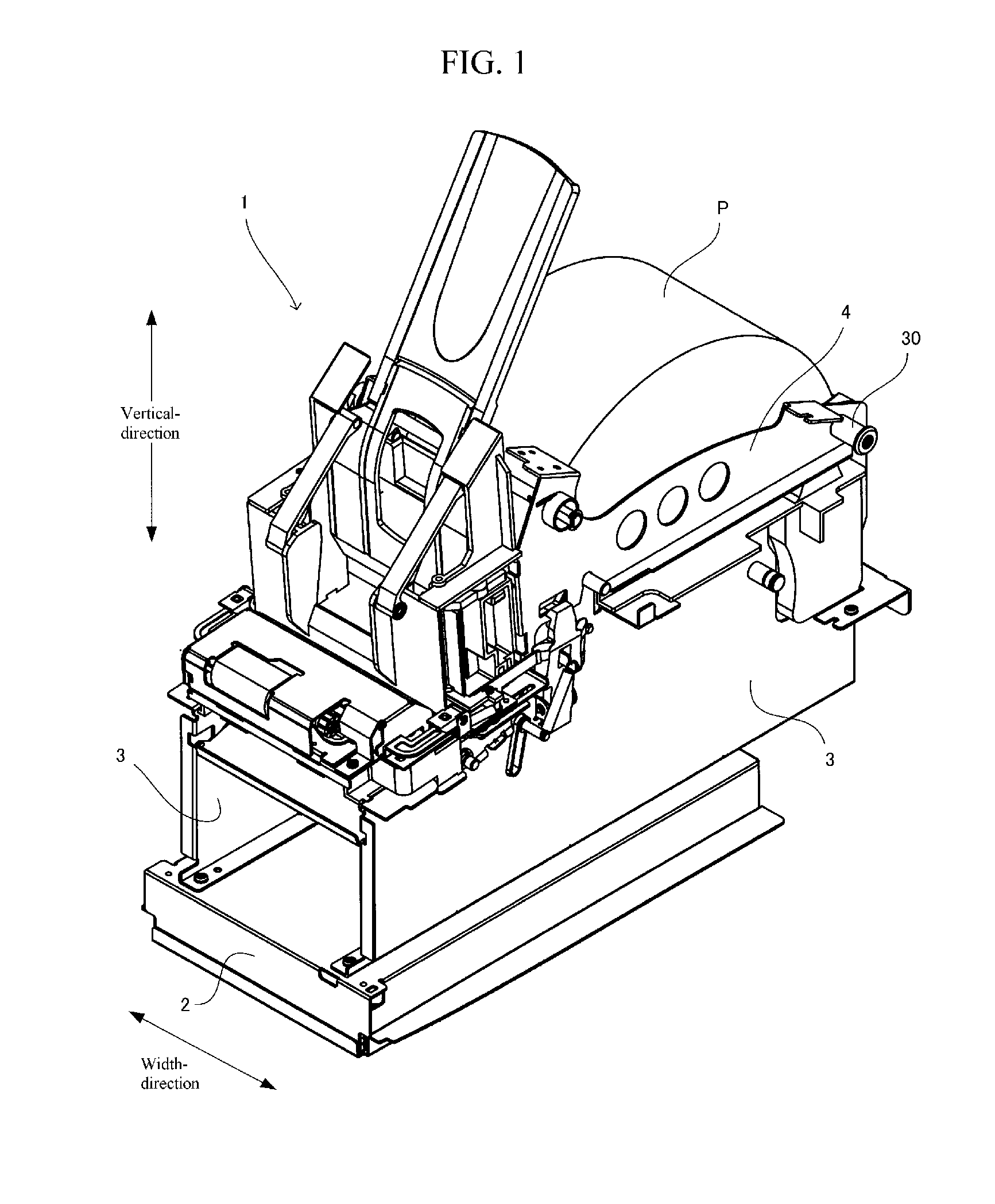

[0036]FIG. 1 is a front perspective view of a printer 1 according to an embodiment of the present invention, which is viewed from a diagonally upper right. Herein, a horizontal direction of the printer 1 (a direction perpendicular to a paper plane in FIG. 3) may be called a width direction.

[0037]As shown in FIG. 1, the printer 1 includes a base chassis 2 having a power supply or a control board embedded therein, a pair of left and right body frames 3 fixed to the base chassis 2, and a pair of left and right cover frames 4 rotatably coupled to the body frames 3. The cover frames 4 are rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com