Cmos-mems switch structure

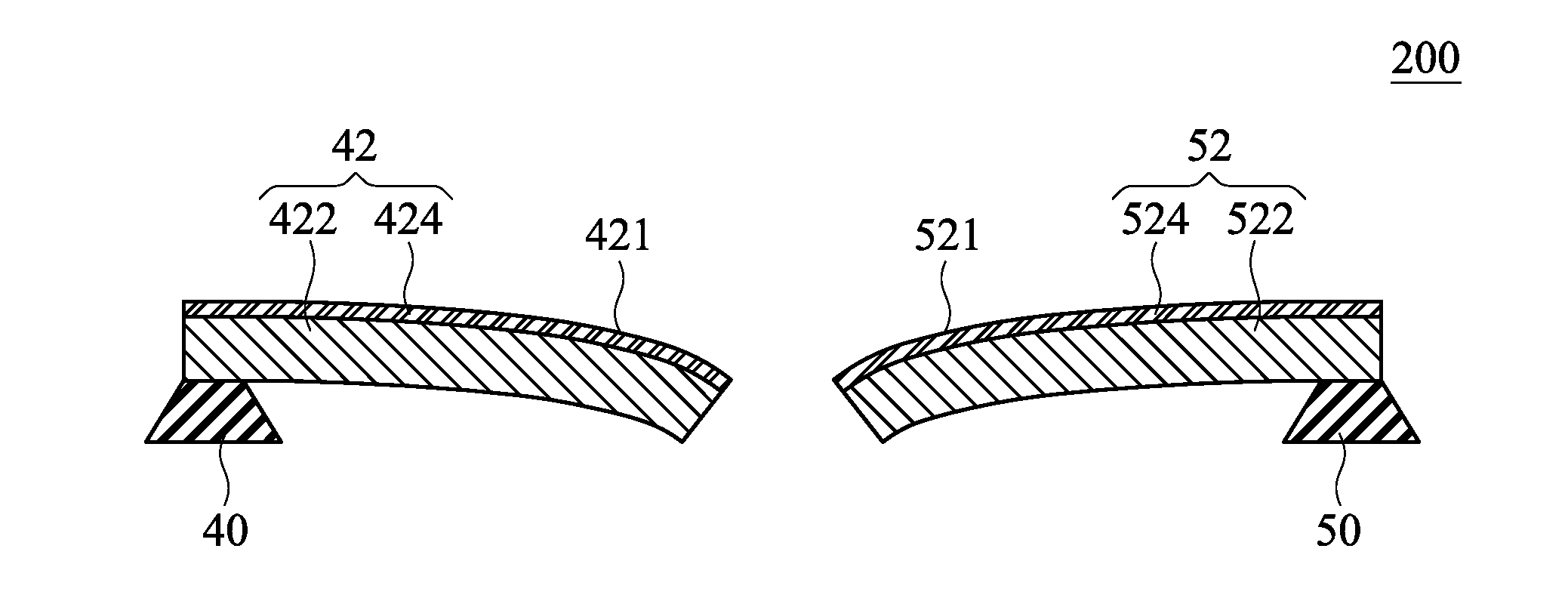

a switch structure and micro-electromechanical technology, applied in the direction of contacts, relays, contact engagements, etc., can solve the problems of the switch structure b>100/b> still has many problems to be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

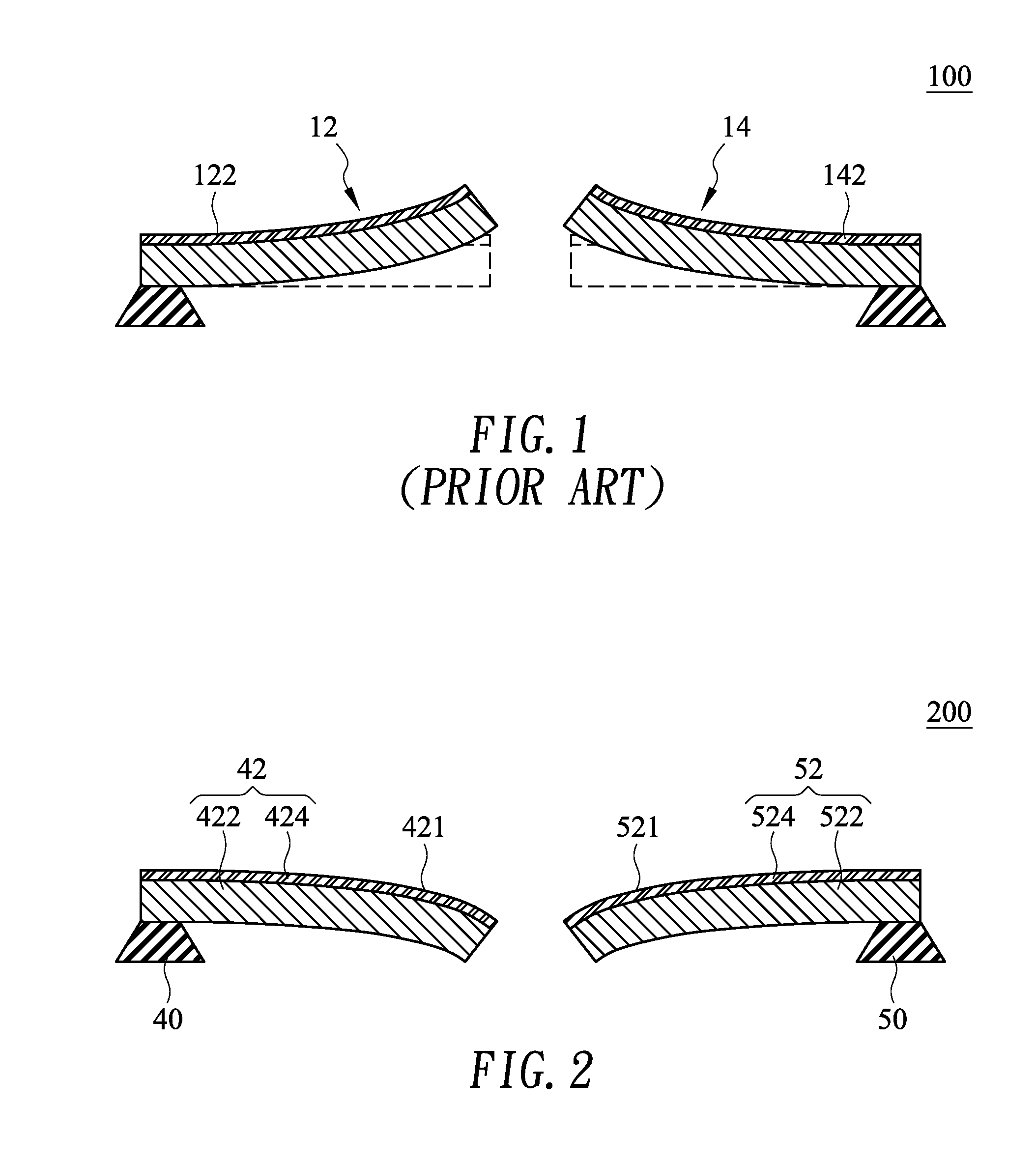

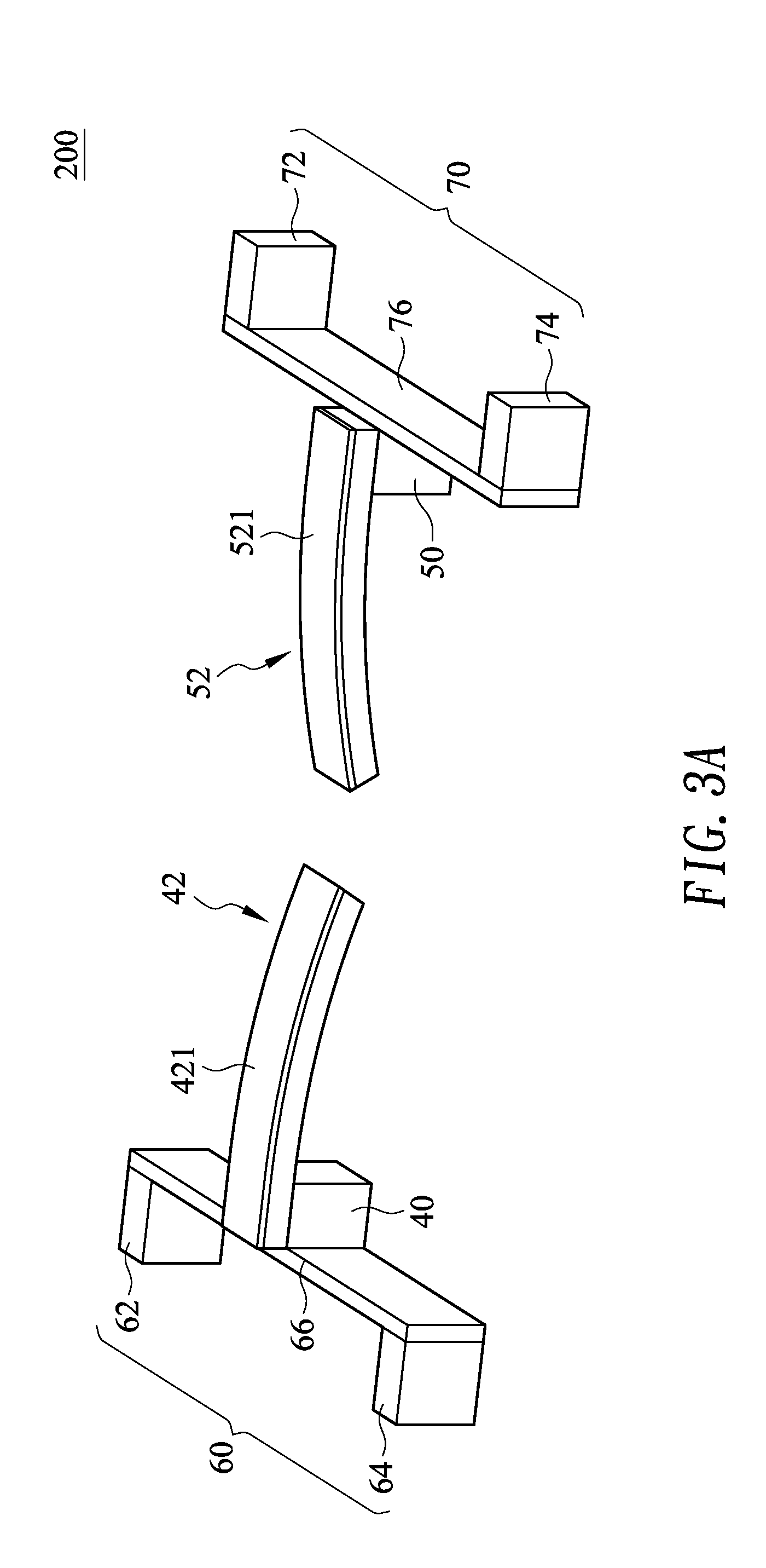

[0023]Referring to FIG. 2, a CMOS-MEMS switch structure 200 according to an embodiment of the present invention includes a first substrate 40, a second substrate 50, a first cantilever beam 42, and a second cantilever beam 52. The CMOS-MEMS switch structure 200 is made by a process incorporating both CMOS and MEMS manufacturing processes. For example, different layers of metals and oxides are stacked up using a standard 0.35-micron CMOS process. Then, MEMS element areas are defined on the stacked layers. Once the sacrificial layer arranged in the MEMS element areas is removed by etching, the desired MEMS structures are released. As the integrated CMOS-MEMS manufacturing processes have been developed to a very mature level, a detailed explanation of such processes is omitted, and only the resultant structure is described herein. It should be noted that all the materials of the disclosed CMOS-MEMS switch structure 200 are materials generally used in an integrated CMOS-MEMS manufacturi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap