Alignment guide with spirit level

a technology of aligning guide and spirit level, applied in the field of aligning guide with spirit level, can solve the problems of acetabular and femoral components, affecting the accuracy of positioning of cup inserters in surgery, and affecting the accuracy of positioning of cups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

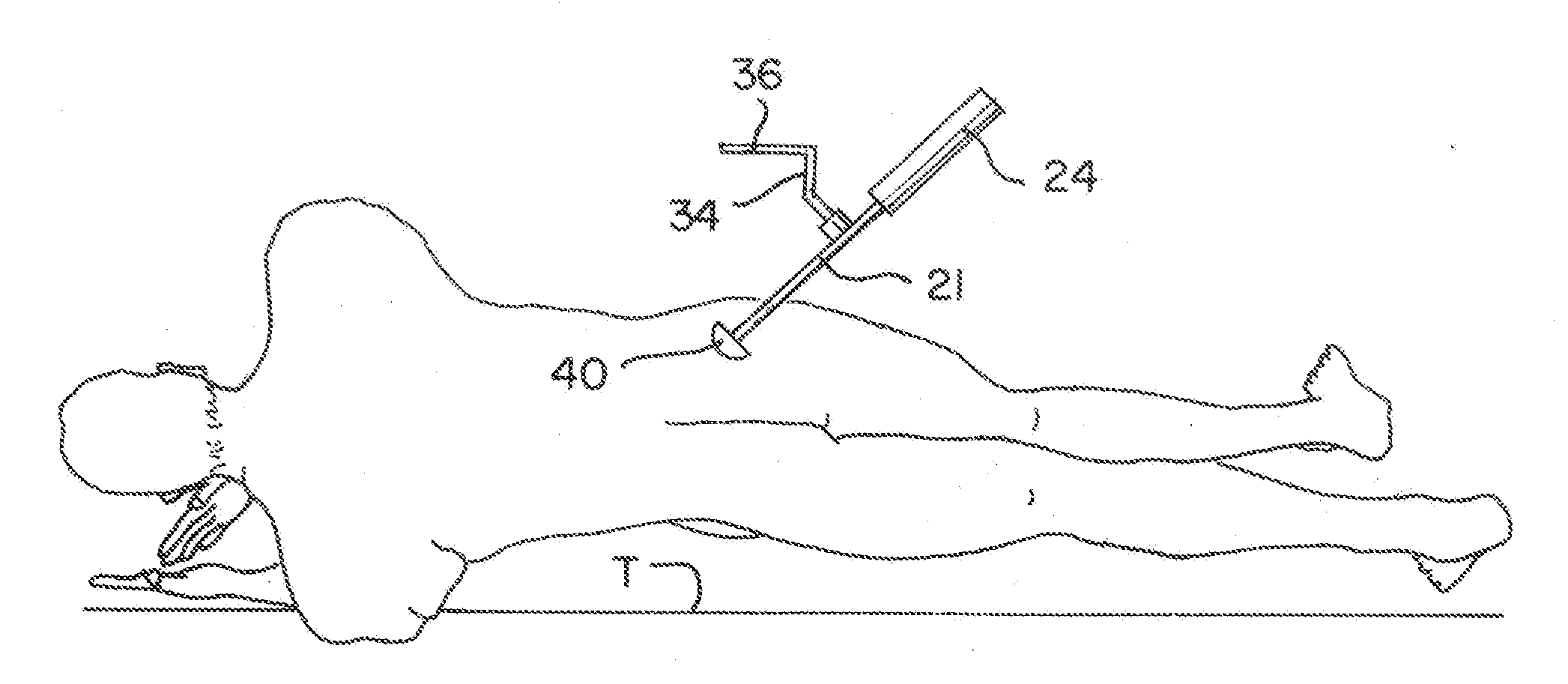

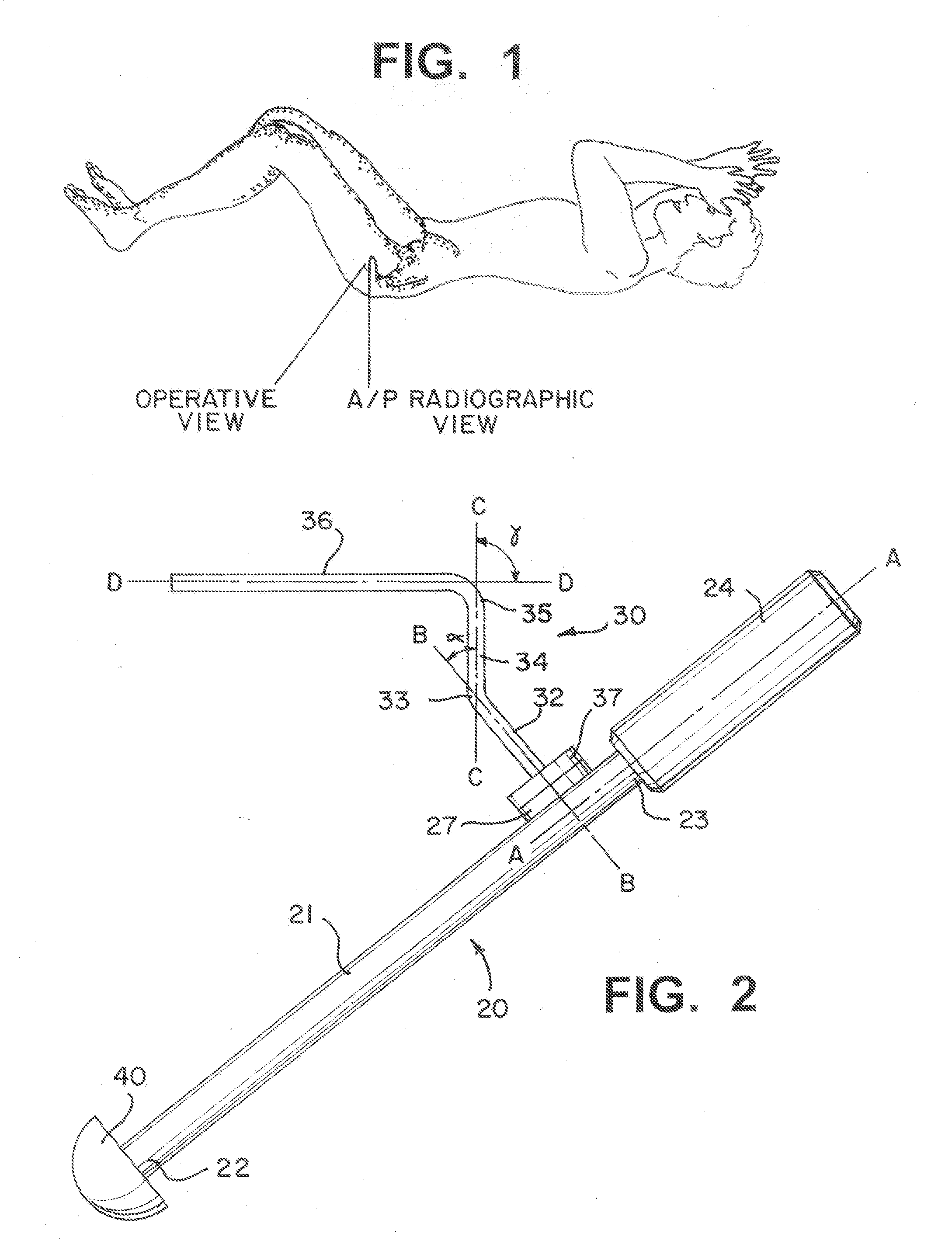

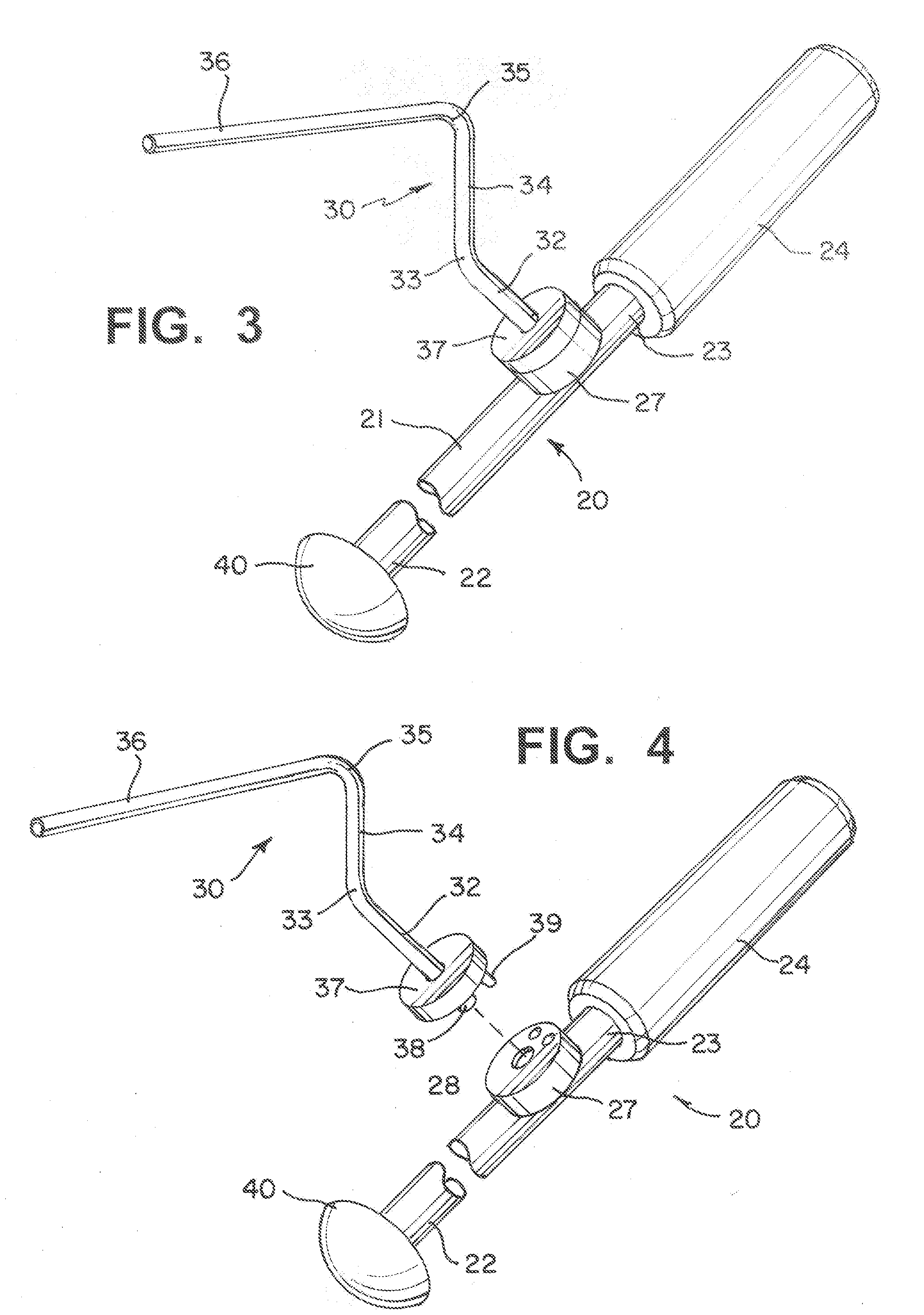

[0041]Referring to FIGS. 2 and 3, the alignment guide is generally referenced as reference numeral 20. Alignment guide 20 includes a shaft 21 having a longitudinal axis A and a guide arm, generally referenced as reference numeral 30, releasably attached to shaft 21. Alignment guide 20 may be attached to a cup or trial 40 at distal end 22 of shaft 21. Alignment guide 20 may include a handle 24 attached at proximal end 23 of shaft 21. Guide arm 30 may be attached to shaft 21 such that shaft 21 and guide arm 30 are co-planar in a first position. Guide arm 30 is preferably configured such that guide arm 30 may be detached from shaft 21, rotated to a second position about a first axis B substantially perpendicular to the longitudinal axis A at which position guide arm 30 is out of plane with shaft 1, and then re-attached to shaft 21. Alternatively, guide arm 30 may be spring biased with respect to shaft 21 such that a user could apply a force to overcome the spring bias to separate guide...

third embodiment

[0049]Referring to Referring to FIGS. 6-9, an alignment guide 220 is depicted. Similar structures are labelled similarly to the corresponding structures of the prior embodiments. Alignment guide 220 includes a shaft 221 having a longitudinal axis A, and a guide arm, generally indicated as reference numeral 230, releasably attached and rotatably attached to shaft 221. Alignment guide 220 may be attached to a cup or trial (not shown) at distal end 222 of shaft 221. Alignment guide 120 may include a handle 224 attached at proximal end 223 of shaft 221. Guide arm 230 may be attached to shaft 221 such that shaft 221 and guide arm 230 are co-planar in a first position. Guide arm 230 is preferably configured such that guide arm 230 may be rotated to a second position about a first axis B substantially perpendicular to the longitudinal axis A at which position guide arm 230 is out of plane with shaft 221. Preferably, guide arm 230 is rotatable in angular increments with respect to shaft 221...

fourth embodiment

[0066]Referring to FIG. 8, the alignment guide is generally referenced as reference numeral 320. Alignment guide 320 includes a shaft 321, having a longitudinal axis A, a guide arm, generally referred to as element 330, which is rotatable with respect to shaft 321, and a spirit level 380 attached to guide arm 330. This embodiment differs from the prior embodiments in that it includes spirit level 380, which facilitates the use of the alignment guide by making it easier for the user to visualize when the alignment guide is in the planned orientation. For example, it may be difficult for the surgeon to judge whether the guide arm is aligned with the patient axis while he or she is holding the device. As such, the spirit level provides an additional indicator allowing the surgeon to check the angle without having to alter his or her viewing position.

[0067]As with prior embodiments, alignment guide 320 may be attached to a cup or trial 340 at distal end 322 of shaft 321. Alignment guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com