Hose For A Piston-Chamber Combination

a technology of piston and chamfer, applied in the direction of pumps, mechanical devices, liquid fuel engines, etc., to achieve the effect of optimizing the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

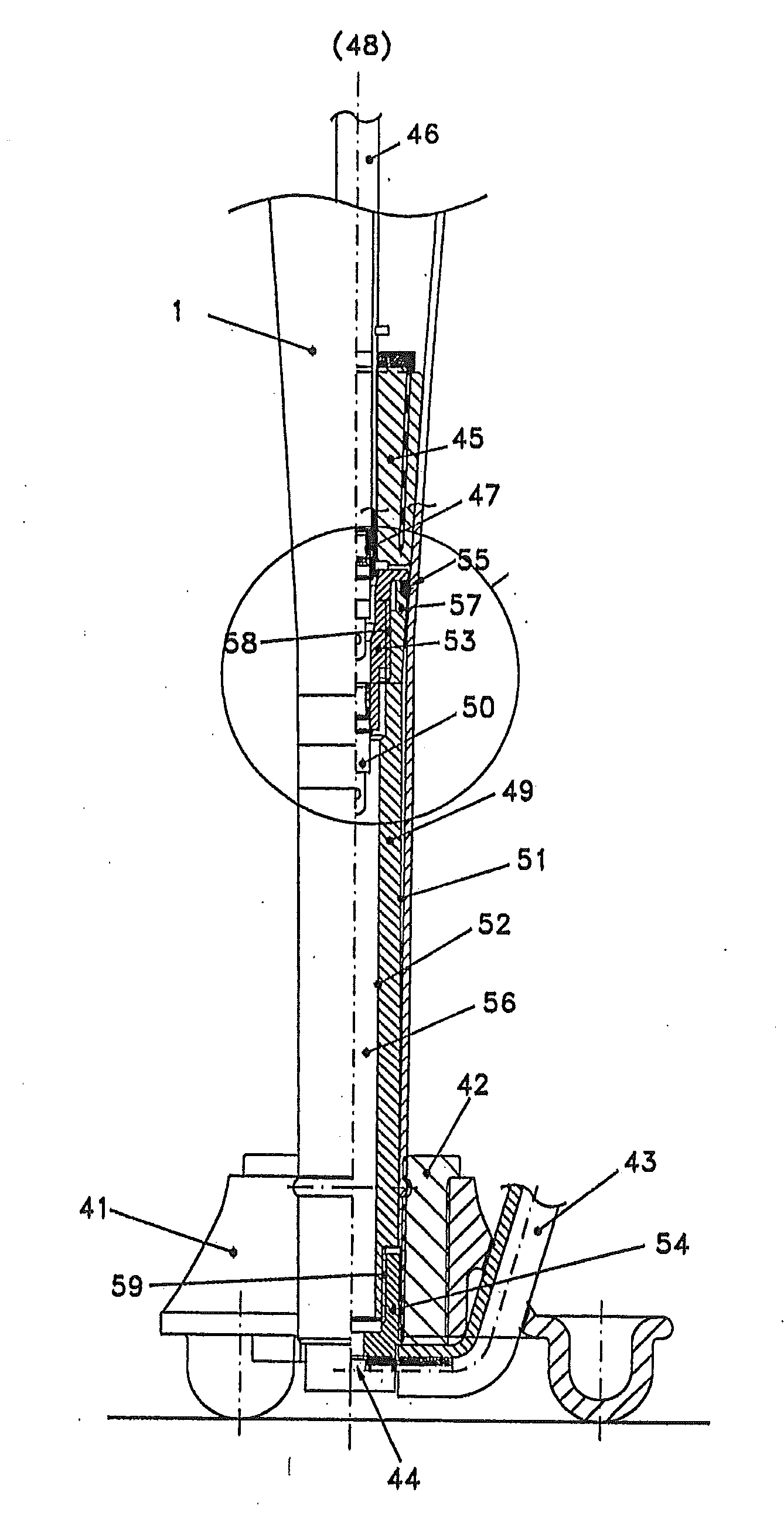

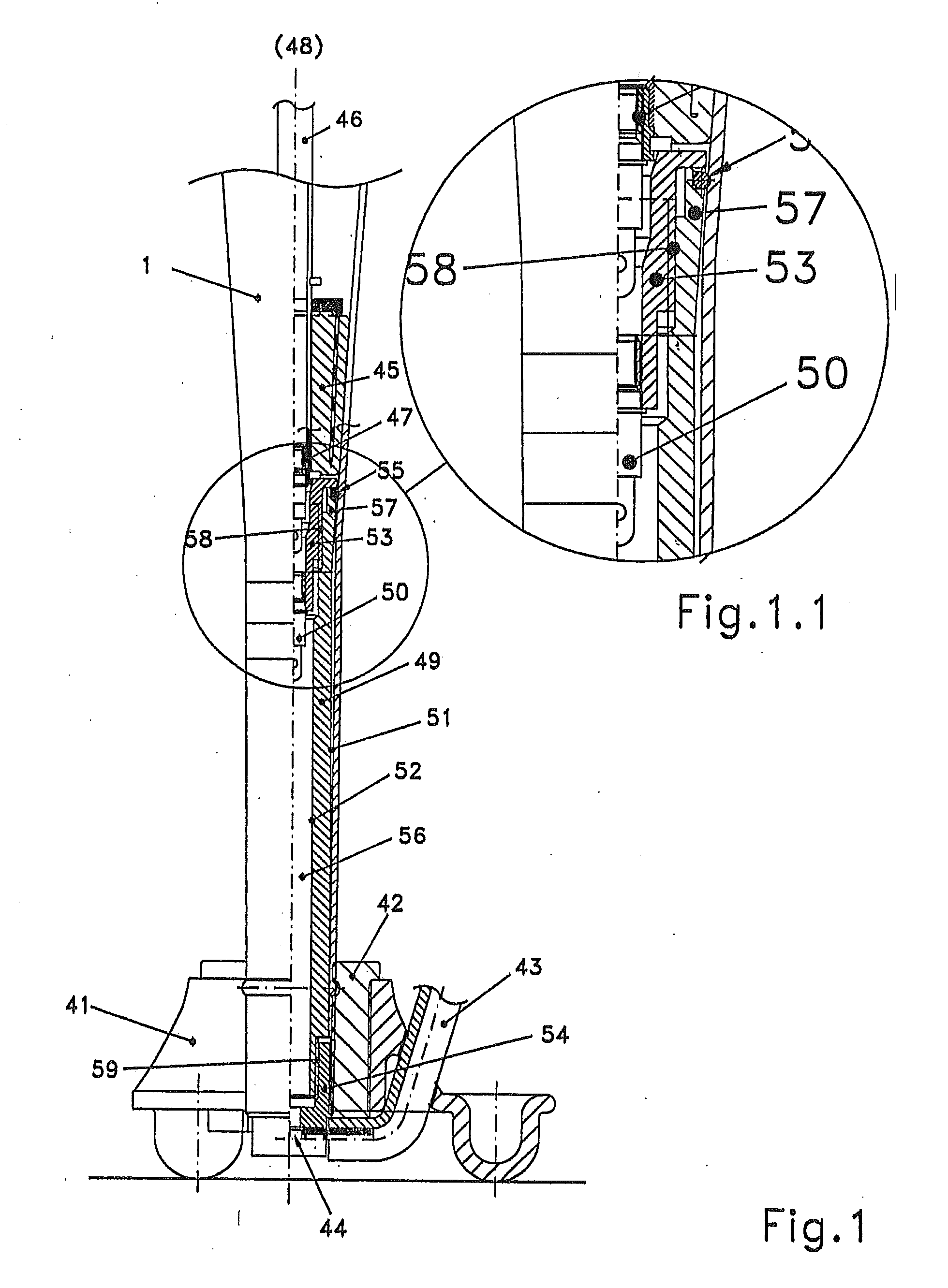

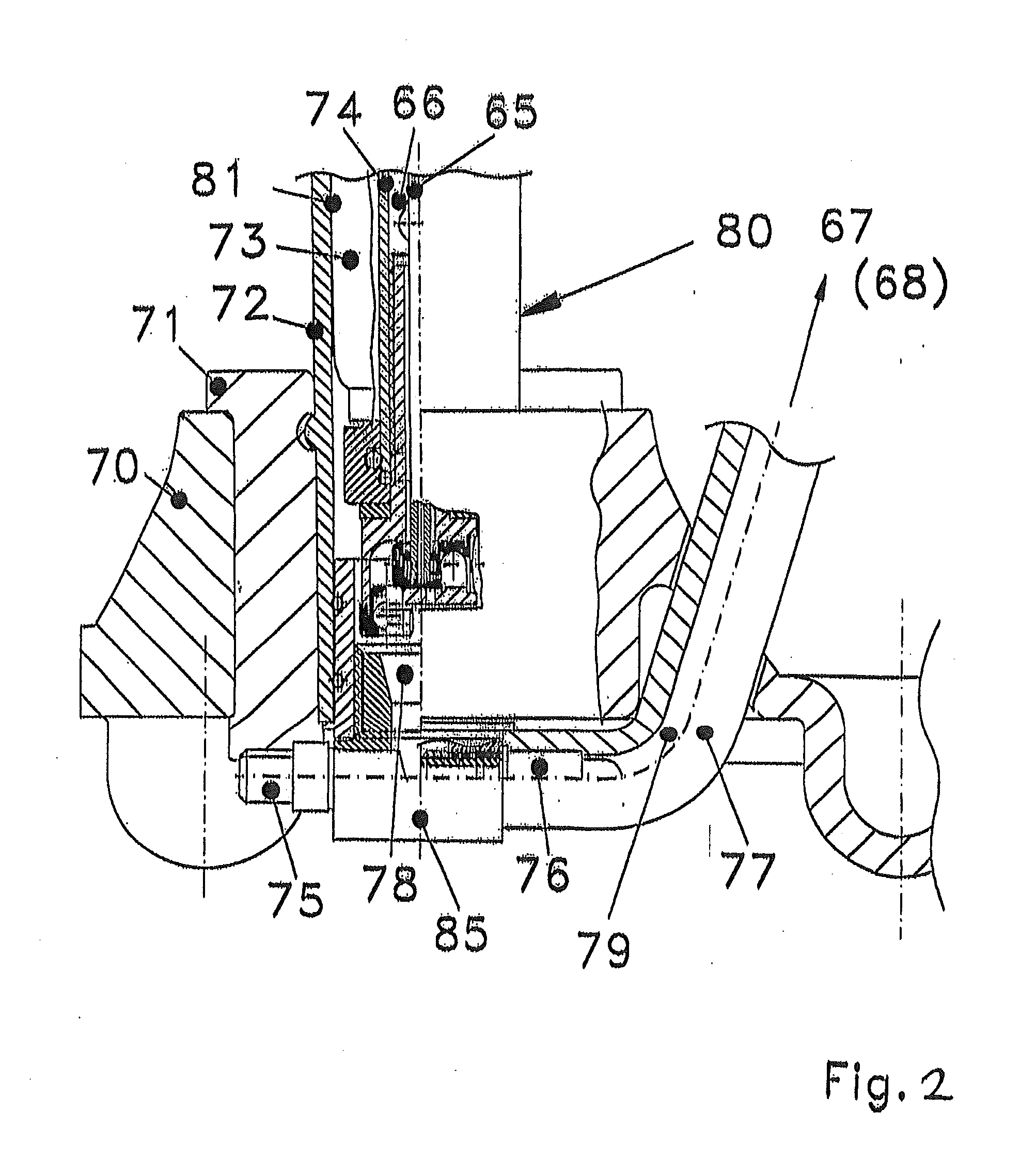

[0042]FIG. 1 shows a bottom part of a chamber of an advanced bicycle floor pump, where additionally the bottom part of the chamber is shown. A flexible manchet 42 assembles the chamber 1 on the foot 41. The hose 43, which is connected to the exit 44 of the pressure expansion vessel 49—this exit is without a check valve. The (schematically drawn) piston 45 is comprising a piston rod 46. At the bottom of the piston rod is a check valve 47 positioned, which is communicating with the external atmosphere (48), and is opening towards the chamber 1, so as to fill the chamber 1 when the piston 45 is moving from a second longitudinal position to a first longitudinal position. An expansion pressure vessel 49 with a chamber 56 is shown, comprising an inlet check valve 50, when open, the chamber 1 is communicating with the hose 43, through an exit 44. The cross-section of the external wall 51 of the expansion pressure vessel 49, with an inner wall 52. The expansion pressure vessel 49 is assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com