Hybrid Motion Ride and Ride Simulator Vehicle

a ride simulator and hybrid technology, applied in the direction of amusements, roundabouts, switchbacks, etc., can solve the problems of passengers' motion movements not reaching the speed and acceleration comparable, and the system has proved to be severely limited in its full capabilities of motion movements,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

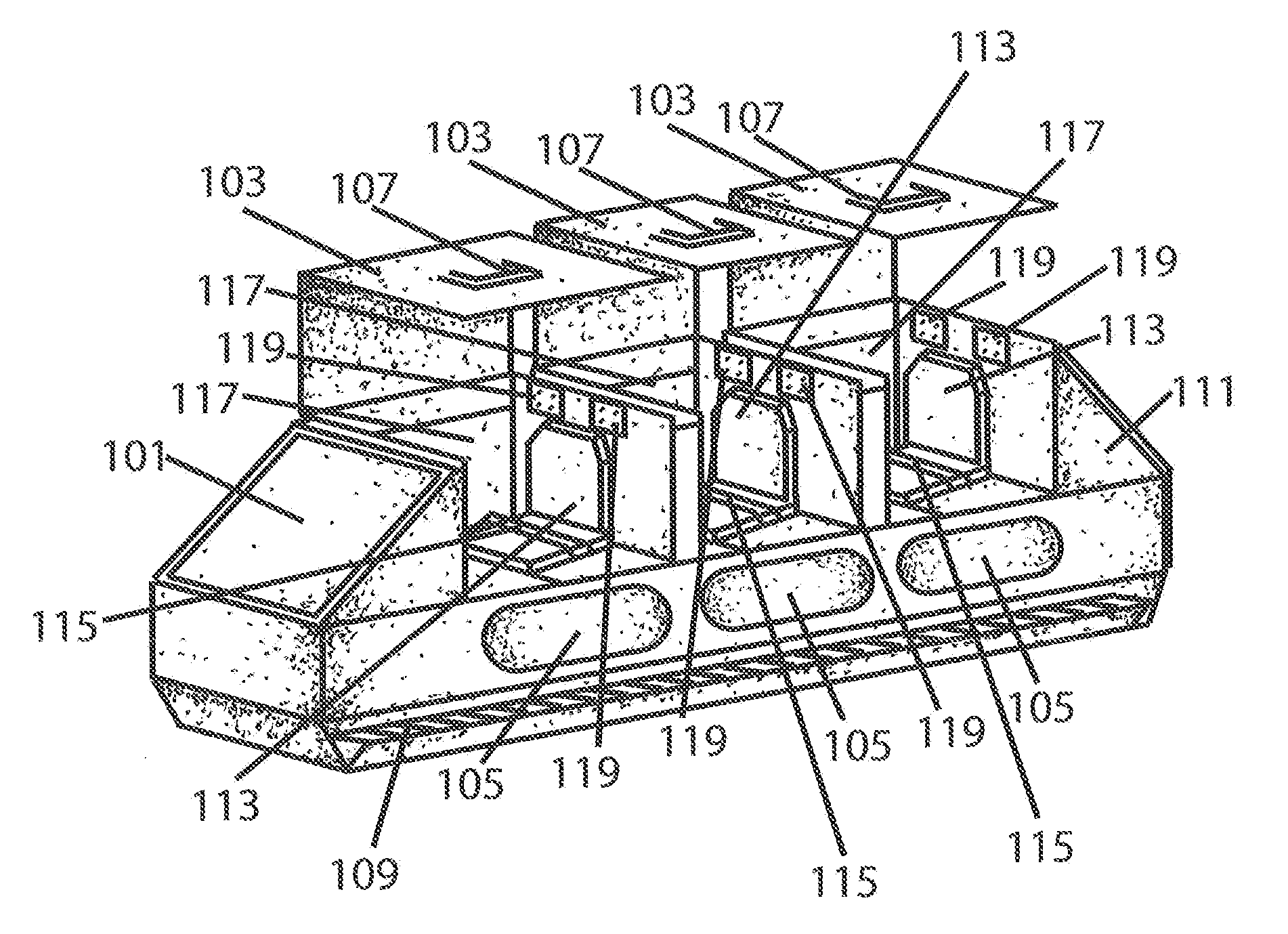

[0034]FIG. 1 is a perspective left-side view of an ERST roller coaster car. Multiple of a single seat passenger 131 (only shown in FIG. 3), not shown in FIG. 1, sits within the vehicle and cannot see outside of the vehicle during the normal operation of a ride as multiple of a lifting door 103, with each multiple of lifting door 103 having a lifting door handle 107, is closed down above each passenger compartment of the vehicle. For gaining access to internal systems of the vehicle a front short service hood 101, a back short service hood 111, and multiple of a service panel 105 can be accessed to get to power systems and simulation technology systems. A safety foot step 109 is for safety and support of passenger unloading and loading.

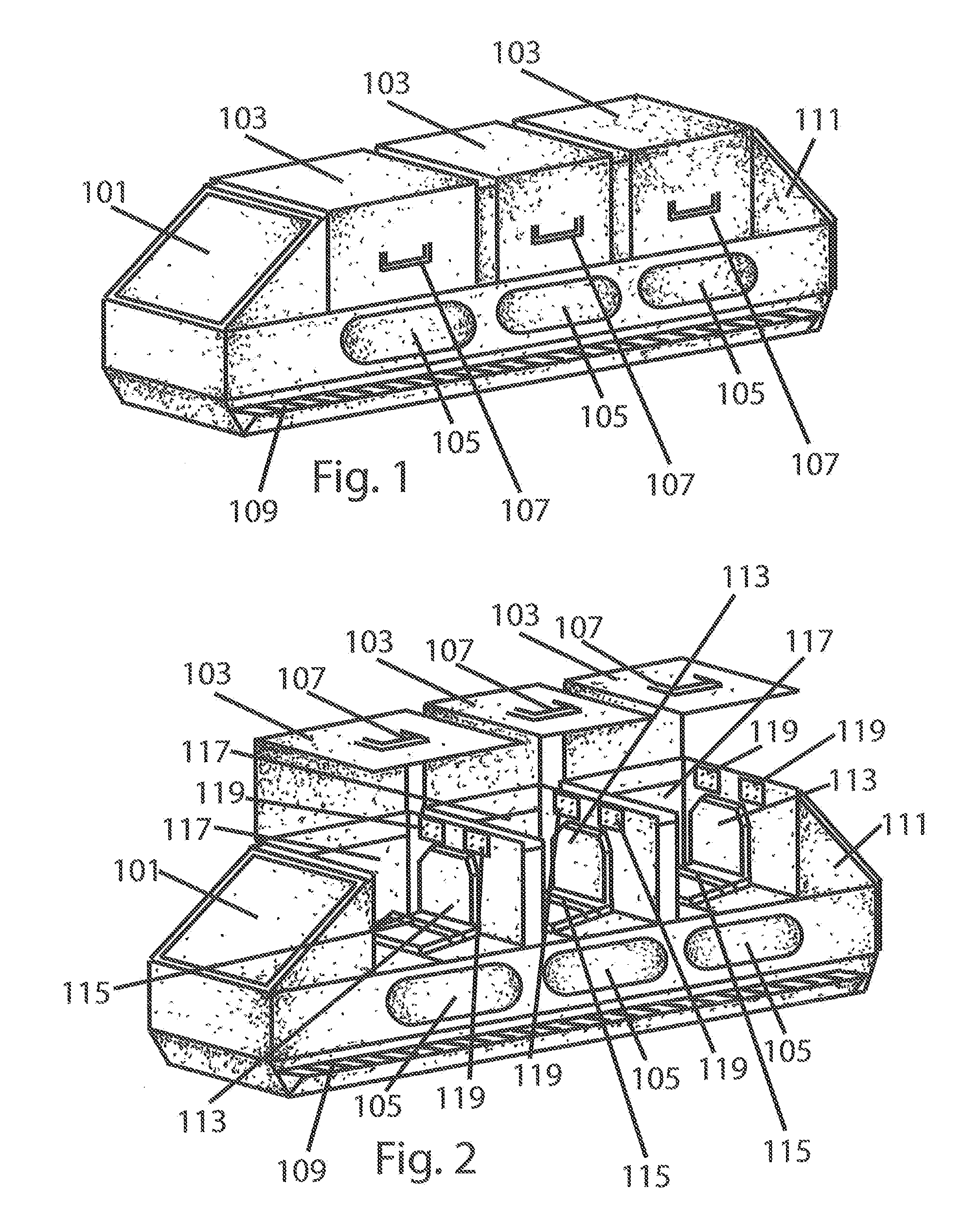

[0035]FIG. 2 is a perspective left-side view of the first embodiment of an ERST roller coaster car with multiple of lifting door 103 open. This is the state of the vehicle in the unloading and loading mode for before and after the normal operation of a...

second embodiment

[0037]FIG. 4 is a perspective left-side and cross-sectional view of an ERST roller coaster car. First row of multiple of a double seat 207 of the vehicle is not shown (first row of double seat 207 is shown in FIG. 6) for improved viewing of internal components. A front long service hood 201 is viewable and multiple of double seat 207 with each double seat 207 having a double seat harness 209 for safety during the normal operation of a ride. Also viewable are a database server system and system internal power source unit 211, a right side long video display 213, and a back long service hood 221. A back double audio speaker 223 is viewable above back row of multiple of double seat 207. Also viewable is a power and data transmission cable system 225.

[0038]FIG. 5 is a perspective left-side view of the second embodiment of an ERST roller coaster car with multiple of a sliding door 203 closed for viewing of the vehicle during the normal operation of a ride. Multiple of a double seat passe...

third embodiment

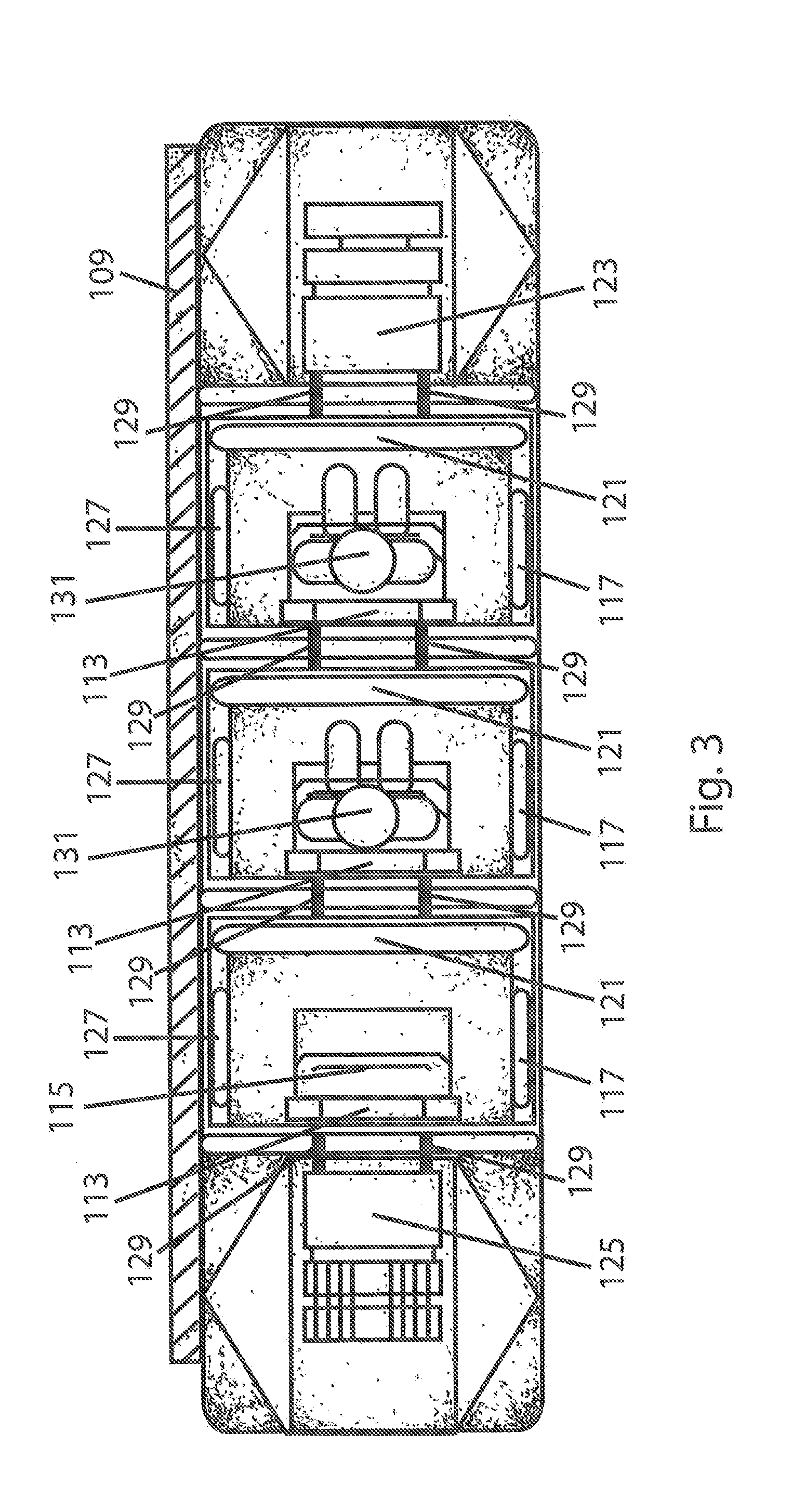

[0040]FIG. 7 is an aerial cross-sectional view of an ERST roller coaster car for viewing of vehicle internal components. A front database enabled video display 137 is directly in front of each of a single seat 113. Across from each of a right side database enabled video display 135 and next to each of multiple of single seat 113 is a left side database enabled video display 133. Viewable are multiple of a single seat harness 115, a safety foot step 109, and multiple of a single seat passenger 131. Also viewable are multiple of a drive assembly 149 and multiple of a short power transmission cable system 147.

[0041]FIG. 8 is an aerial view of an offsite database server system 141 for use by the third embodiment of an ERST roller coaster car. Offsite database server system 141 is located offsite in an area that is external to and away from the ride vehicle making offsite database server system 141 an external database server to the ride vehicle.

[0042]FIG. 9 is a perspective left-side vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com