Open-valve Port Fuel Injection Of Alcohol In Multiple Injector Engines

a fuel injection and injector engine technology, applied in the direction of combustion air/fuel air treatment, electric control, instruments, etc., can solve the problems of reducing the efficiency of the engine, so as to reduce the autoignition and increase the stability of the gaseous mixture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

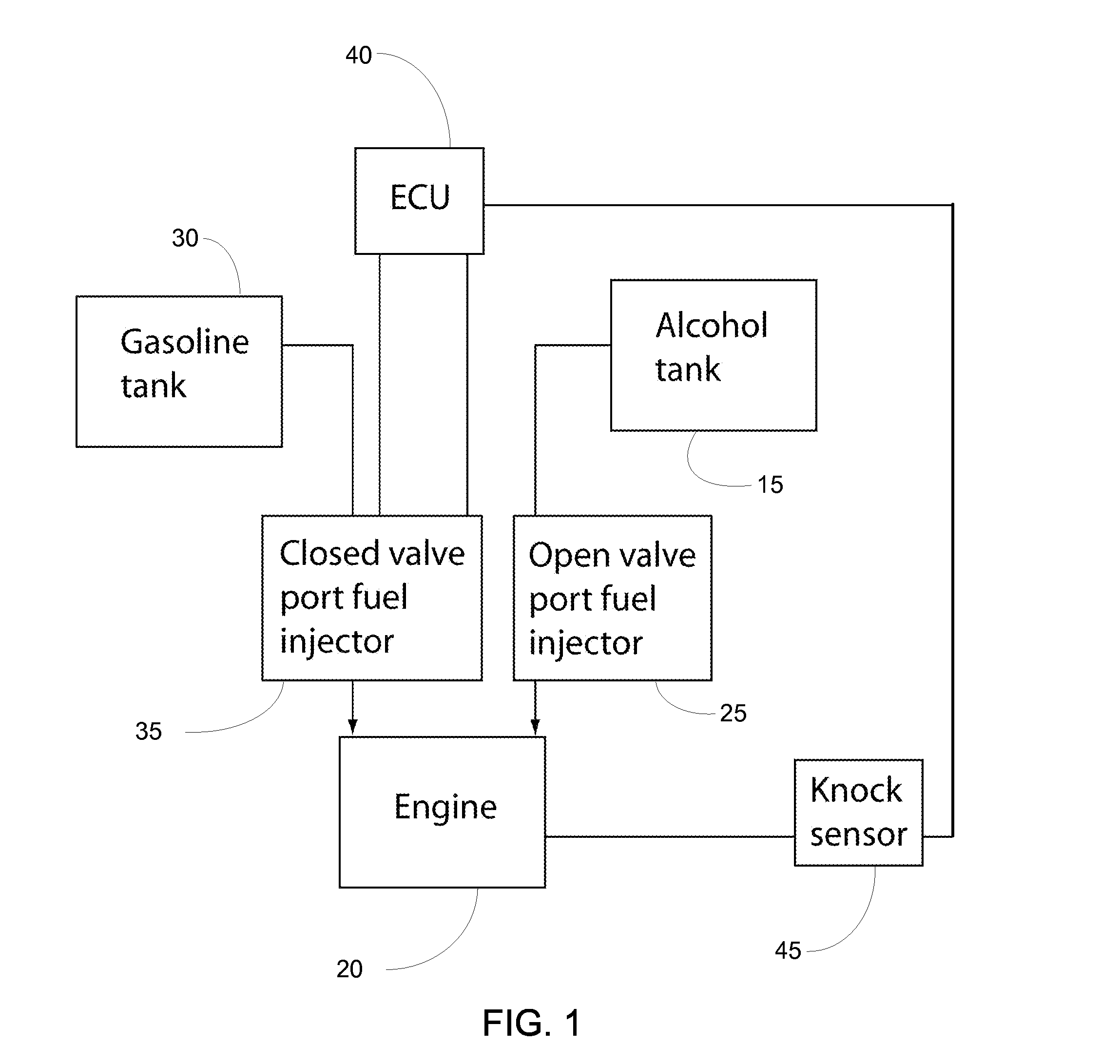

[0014]FIG. 1 shows a schematic diagram of a gasoline engine where alcohol or some other fluid from a secondary tank 15 is introduced into the engine cylinder 20 by an open-valve port fuel injector 25 and the gasoline from the primary tank 30 is introduced by a closed-valve port fuel injector 35. While gasoline and alcohol are shown in FIG. 1 as being stored in primary tank 30 and secondary tank 15, respectively, the invention is not limited to this embodiment. Any primary fuel may be used in the primary tank 30, including gasoline and gasoline-alcohol mixtures. Similarly, any fuel which contains alcohol as a constituent can be used in the secondary tank 15. This includes a fuel which contains only alcohol or an alcohol-water mixture. In this embodiment, one fuel injector (the “open-valve port fuel injector”) 25 injects fuel when the intake valve is open or more open than the other fuel injector (the “closed-valve port fuel injector”) 35. For a given amount of fuel that is introduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com