Borehole tool heat transfer altering system and method, and method of heating borehole fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

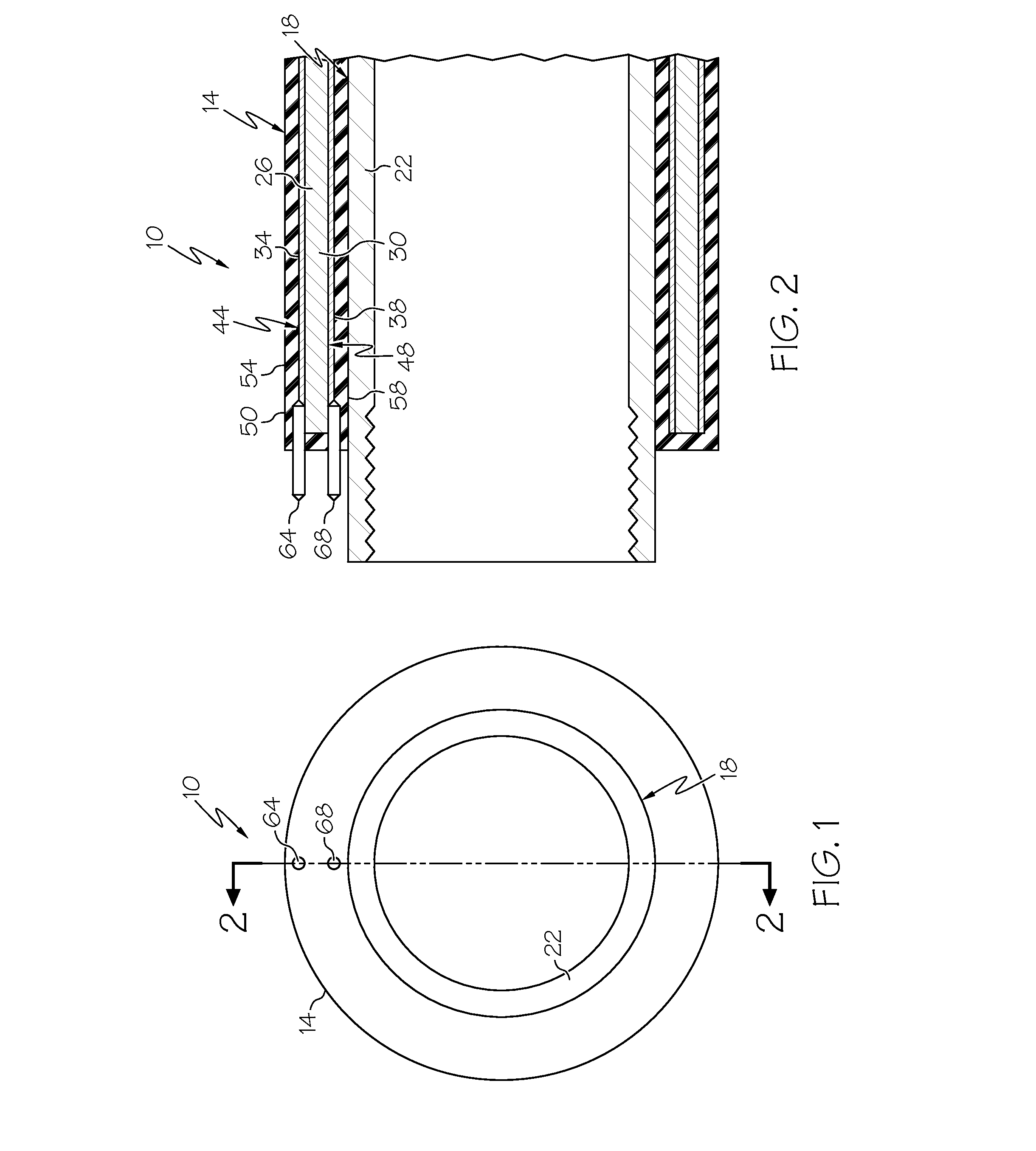

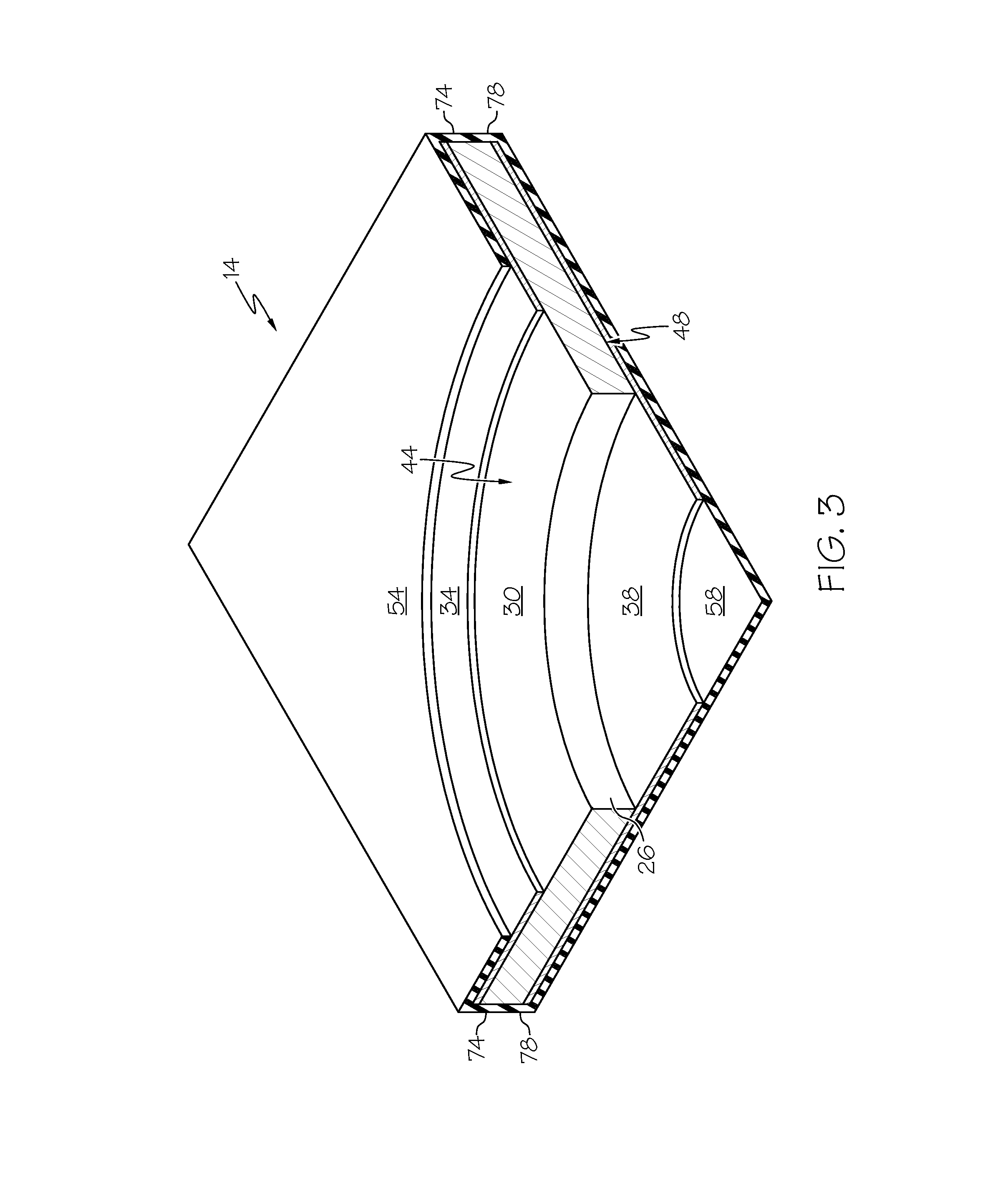

[0014]A detailed description of one or more embodiments of the disclosed apparatus and method are presented herein by way of exemplification and not limitation with reference to the Figures.

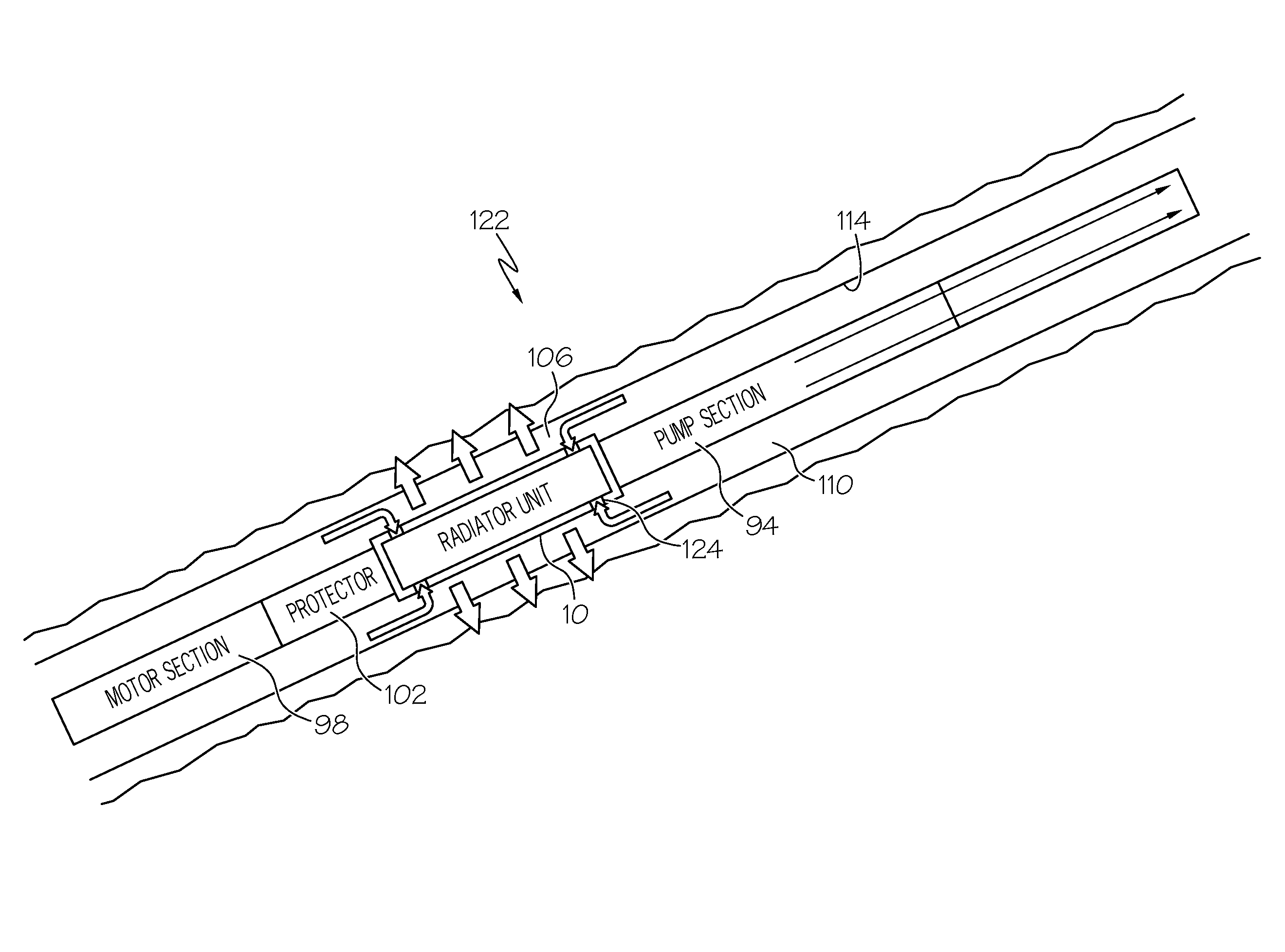

[0015]Referring to FIGS. 1-3, an embodiment of a borehole tool heat transfer altering system is disclosed generally at 10. The borehole tool heat transfer altering system 10 works on the principle of the Seebeck effect to convert electricity supplied to a thermoelectric material directly into temperature differences across the thermoelectric material, and uses no moving parts in the process. The borehole tool heat transfer altering system 10 includes, a layered assembly 14, conformed to a surface 18 (an outer surface in this embodiment) of a tubular 22. The layered assembly 14 has a core 26 of thermoelectric material 30, with conductors 34, 38, shown herein as layers of conductive material, electrically bonded to opposing surfaces 44, 48 of the thermoelectric material 30. A protector 50 including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com