Ring flip-top tube container

a tube container and flip-top technology, applied in the field of ring flip-top tube containers, can solve the problems of increased raw material costs, complicated assembly process, and difficult to elegantly display the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

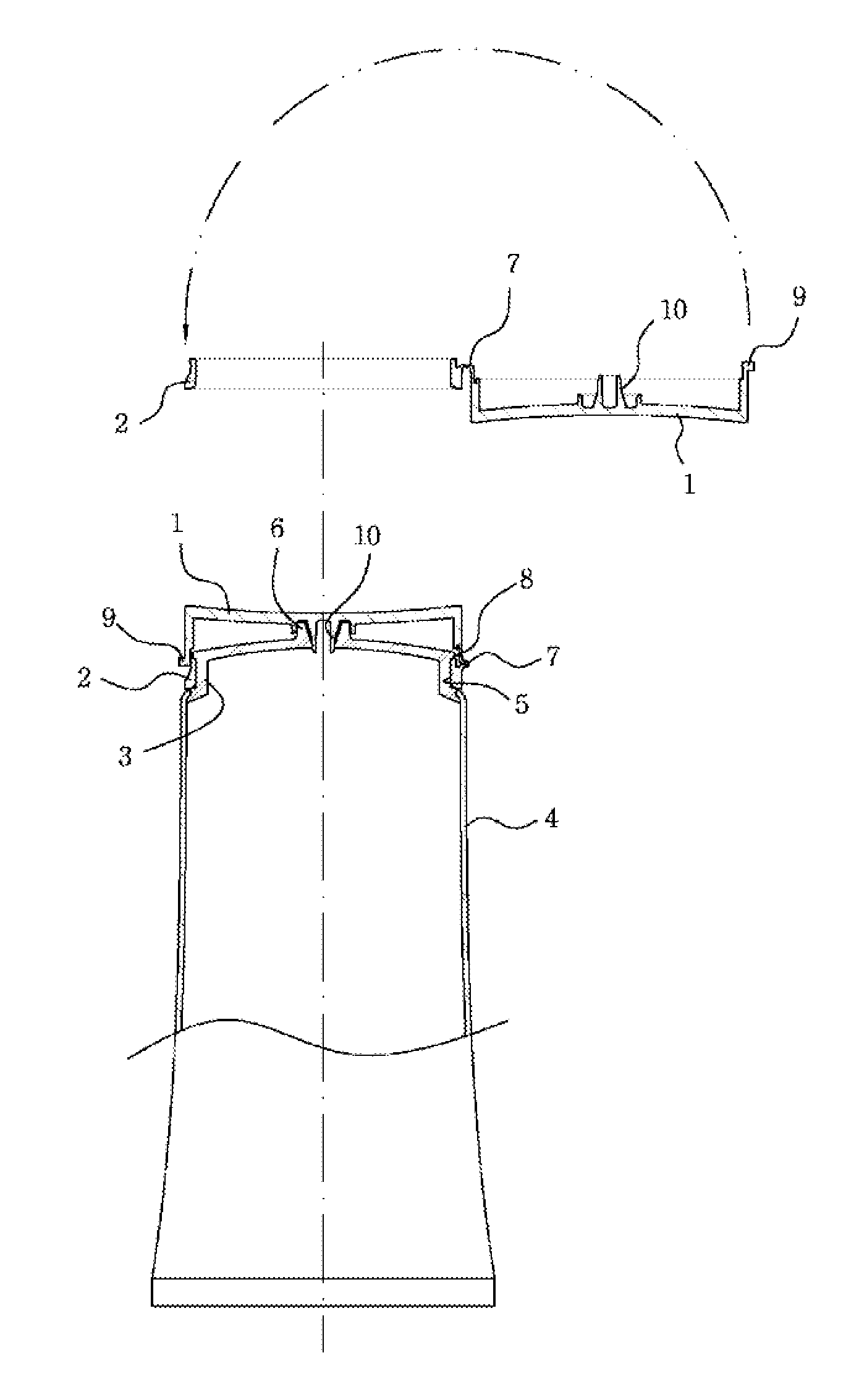

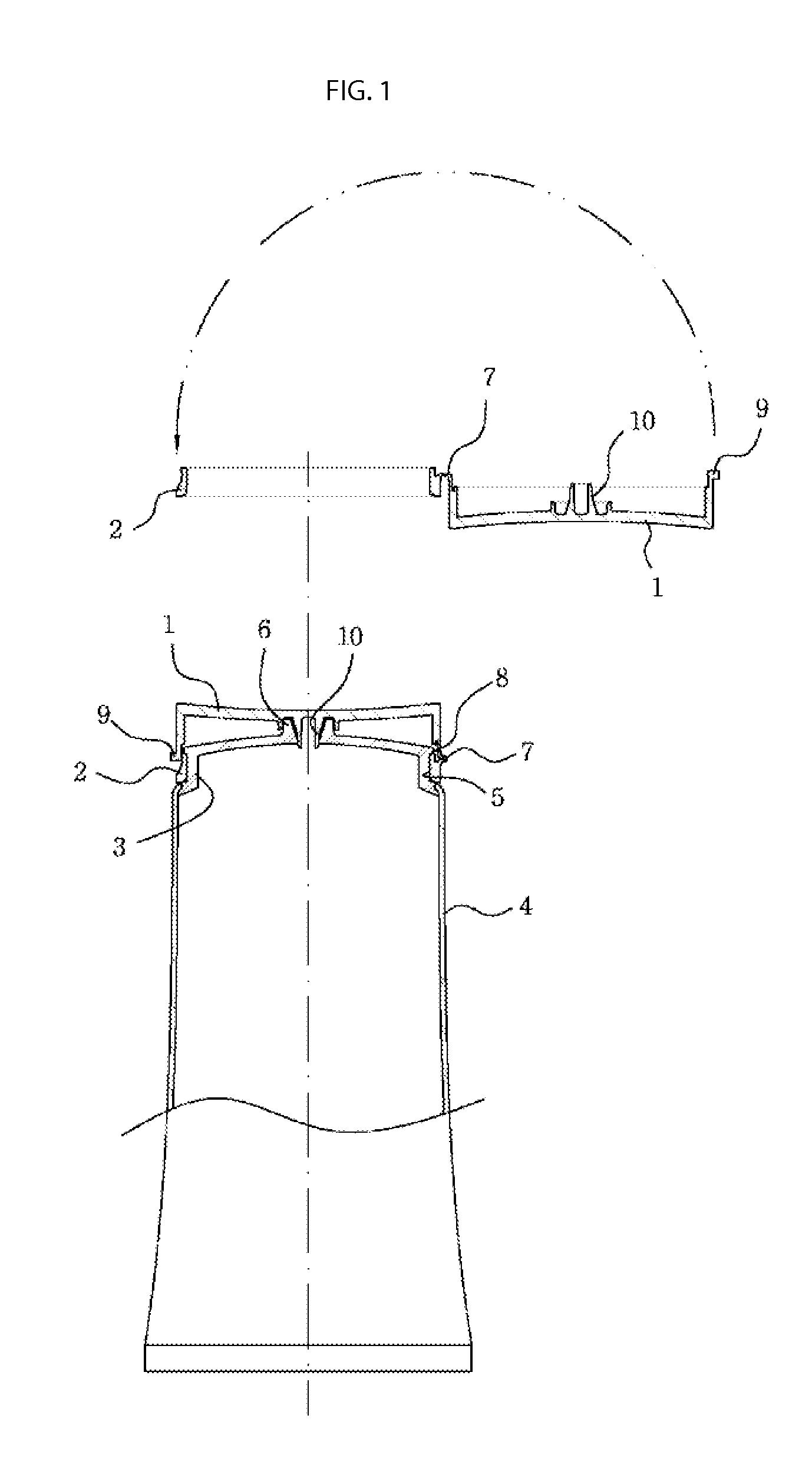

[0015]The invention is further described in a detail with reference of drawings of the invention in the followings. The same figure number in each drawing indicates the same component.

[0016]As to the ring flip-top tube container in the invention, a tube body 4 is used for providing a space accommodating cosmetic, and can be made of soft material, for example, PE. The lower part of the tube body 4 can be sealed with the adoption of the well-known technique in the prior art, and the upper part of the tube body 4 is opened. Furthermore, the upper part of the tube body (4) is opened and connected with the lower part of the tube neck (3) and constitutes one body;

As to the ring flip-top tube container in the invention, the tube neck 3 is connected with the upper part of the tube body 4 and may be made of soft material, for example, PE. the tube neck 3 is formed with a ring-shaped groove 5 being capable of fastening and fixing the lower flip-top cap 2 along the outer peripheral surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com