Adjustable exhaust baffling device

a technology of baffling device and exhaust, which is applied in the direction of exhaust treatment, machines/engines, mechanical equipment, etc., can solve the problems of affecting the performance of these engines, unable to substantially control the noise of these devices, and devices that are difficult to fit in tight applications on cars, etc., to achieve the effect of maximizing engine performance and being easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

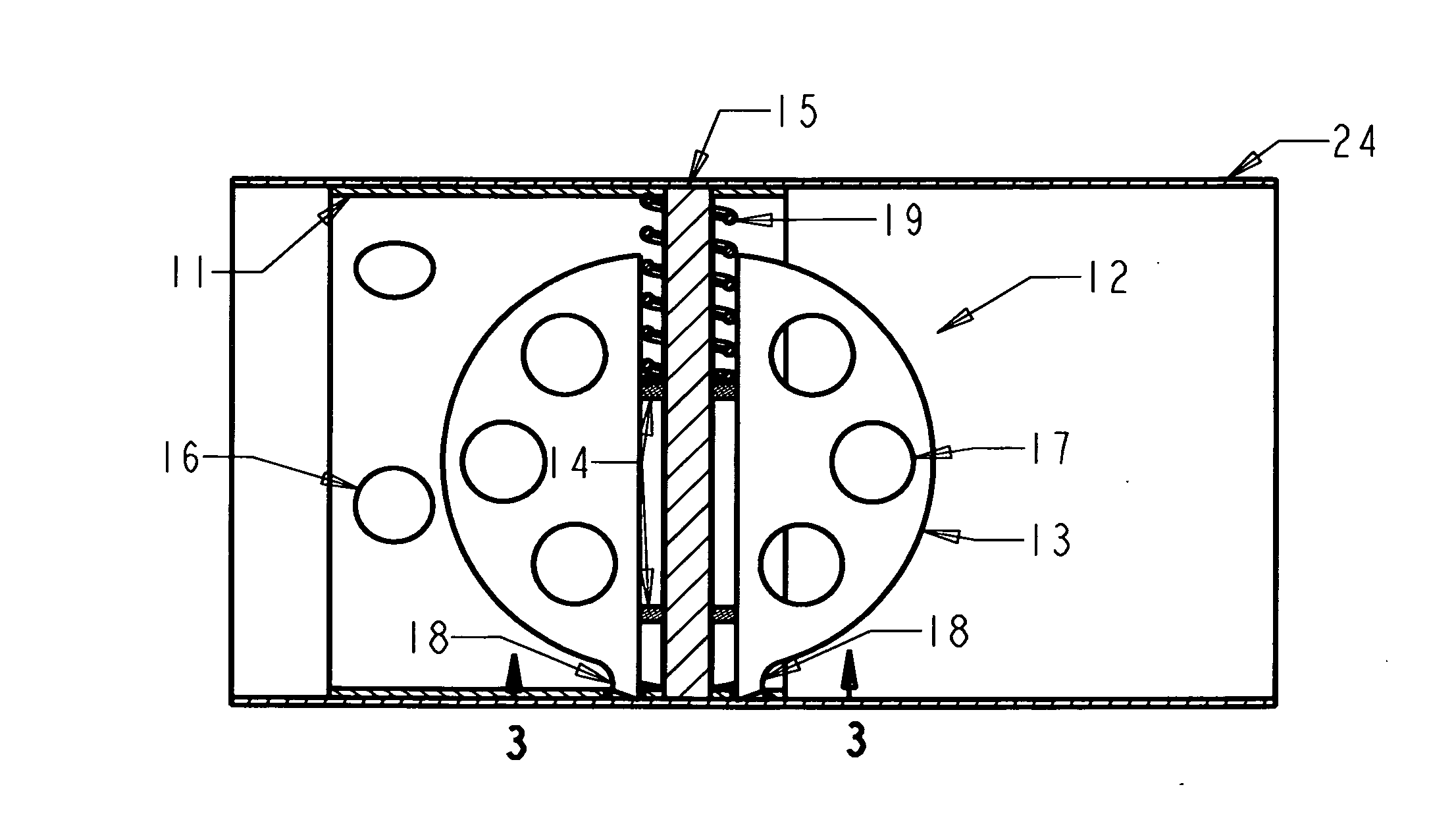

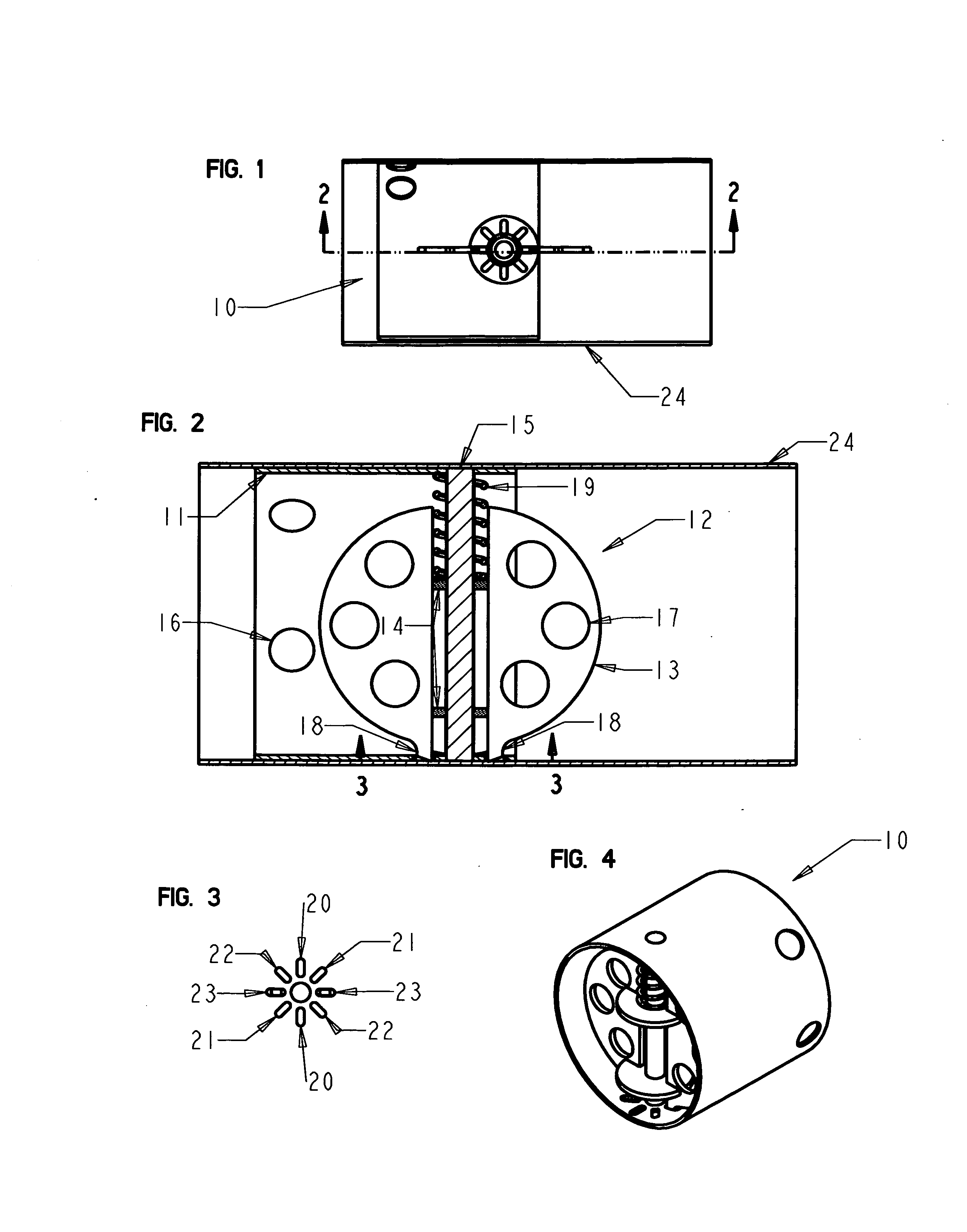

[0014]FIG. 1 shows a top view of the present invention generally designated 10 installed in a section of an existing exhaust system 24.

[0015]FIG. 2 illustrates two primary parts of the device. The first part is the tubular body 11 which creates the main body of the device. The second primary part is the baffle assembly generally designated 12 which provides the operational mode change as described by the present invention.

[0016]The baffle assembly 12 consists of two baffle plates 13 connected by two lifting tabs 14. The lifting tabs 14 provide for a means of lifting axially, and rotating about the pivot shaft 15. Each baffle plate 13 has a varying quantity, size, and pattern of passages 17 through which exhaust gas may pass when place transverse to exhaust flow. Each baffle plate 13 has a locking tab 18 that extends towards the tubular body 11 where there are corresponding slots that receive said tabs causing the baffle assembly 12 to rotationally lock in a position when acted upon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com