Cube-corner retroreflective sheeting

a retroreflective sheeting and cube-corner technology, applied in the direction of instruments, roads, constructions, etc., can solve the problems of low brightness around the boundary, inferior design, and the inability to make less boundaries, and achieve excellent design and excellent rotation angle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0068](First Embodiment)

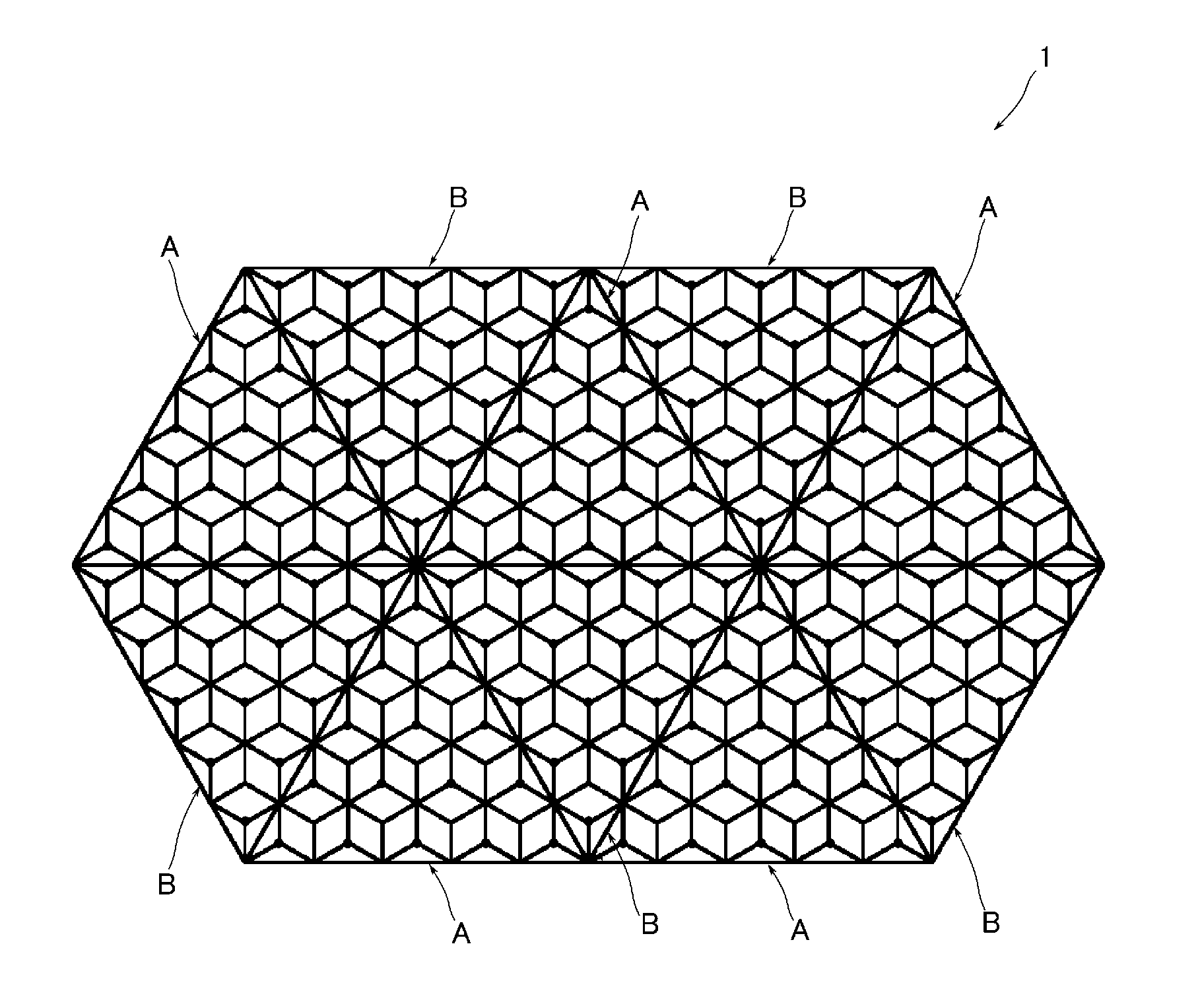

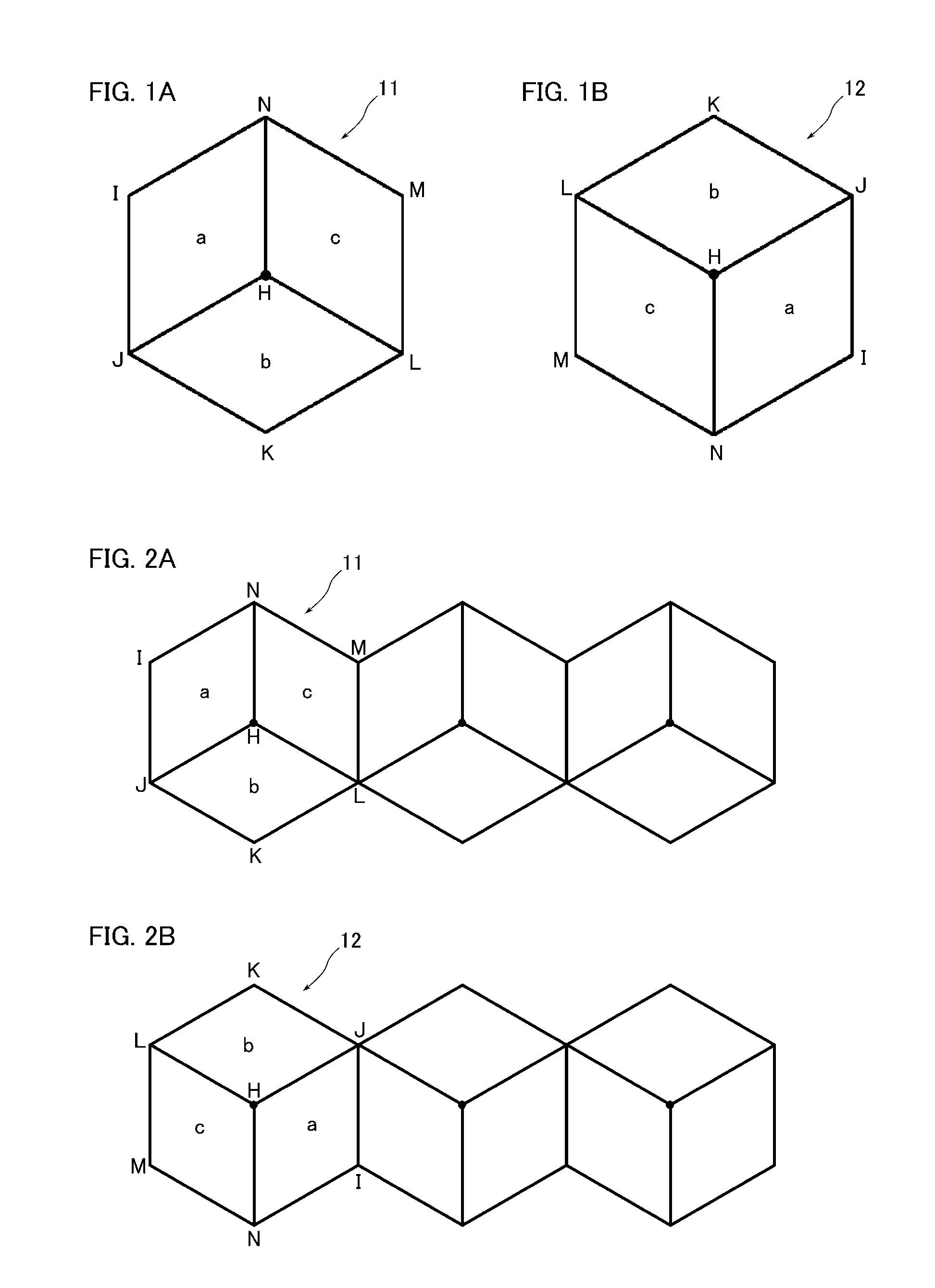

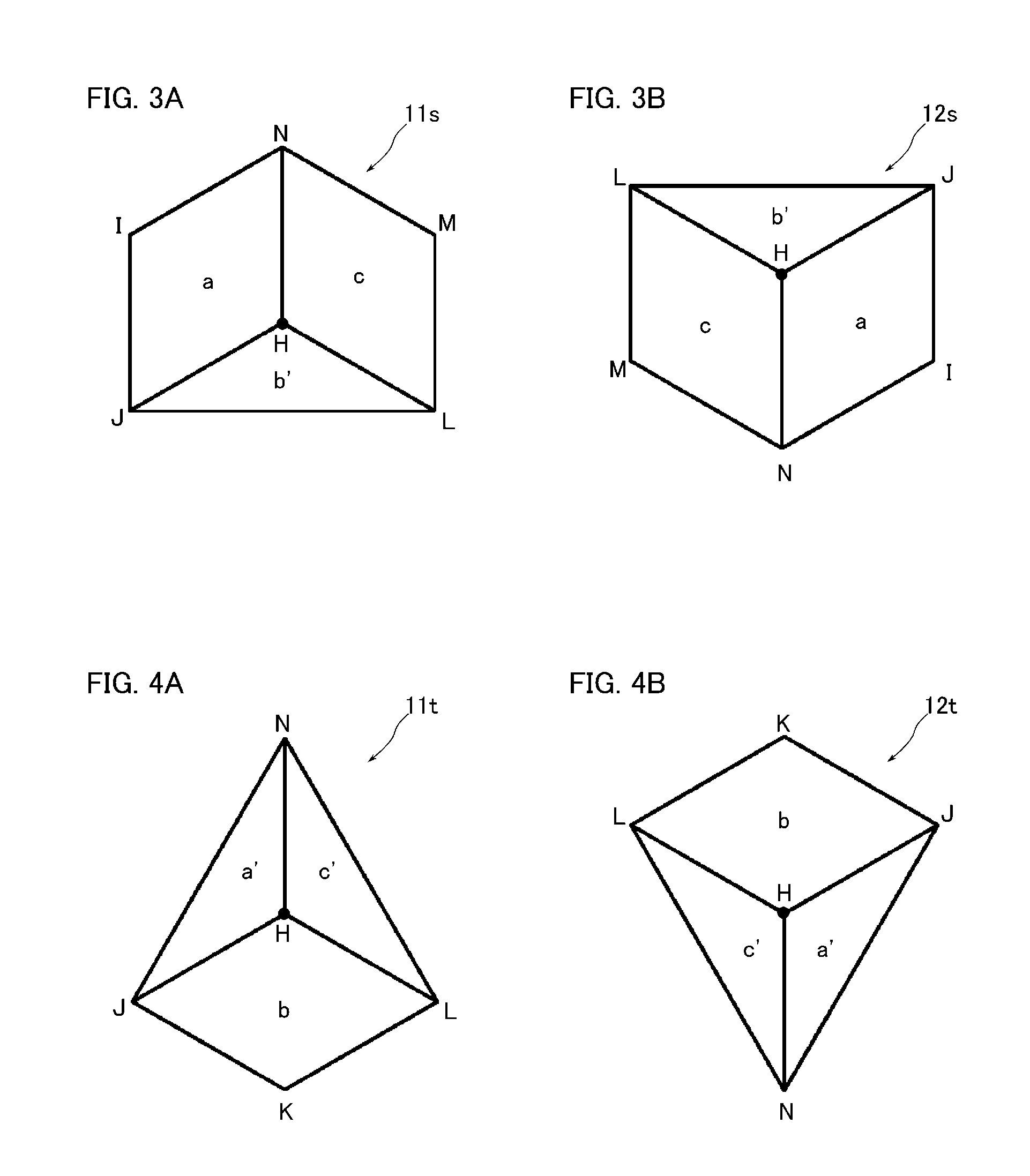

[0069]FIG. 1 shows enlarged views of hexagonal cube-corner retroreflective elements in cube-corner retroreflective sheeting according to a first embodiment of the present invention. As shown in (A) and (B) of FIG. 1, the cube-corner retroreflective elements in the present embodiment are hexagonal cube-corner retroreflective elements.

[0070]As shown in FIG. 1(A), a hexagonal cube-corner retroreflective element 11 has three quadrangular reflective lateral surfaces a, b and c that are congruent. The reflective lateral surface a is a square having apexes H, N, I and J, the reflective lateral surface b is a square having apexes H, J, K and L, and the reflective lateral surface c is a square having apexes H, L, M and N. The reflective lateral surfaces a, b and c therefore has one apex H in common. That is, the apex H is an apex of a cube-corner retroreflective element that three reflective lateral surfaces have in common. In addition, the adjacent reflective lateral...

second embodiment

[0088](Second Embodiment)

[0089]Next, a second embodiment of the present invention will be described in detail with reference to FIGS. 7 to 9. Here, components that are identical or similar to those in the first embodiment are designated by the same reference numerals and redundant description will not be repeated unless the description is particularly stated.

[0090]FIG. 7 shows views in which hexagonal cube-corner retroreflective elements of cube-corner retroreflective sheeting according to the second embodiment of the present invention are arranged, and corresponds to FIG. 2 in the first embodiment. FIG. 8 shows plan views of regions in the cube-corner retroreflective sheeting according to the present embodiment in which the cube-corner retroreflective elements are arranged in a closest-packed state, and FIG. 9 is a plan view showing the cube-corner retroreflective sheeting according to the present invention in which the regions of the cube-corner retroreflective sheeting shown in F...

third embodiment

[0096](Third Embodiment)

[0097]Next, a third embodiment of the present embodiment will be described in detail with reference to FIGS. 10 and 11. Here, components that are identical or similar to those in the first embodiment are designated by the same reference numerals and redundant description will not be repeated unless the description is particularly stated.

[0098]FIG. 10 is a plan view showing cube-corner retroreflective sheeting according to the third embodiment of the present invention, and FIG. 11 is a perspective view of the cube-corner retroreflective sheeting shown in FIG. 10.

[0099]As shown in FIGS. 10 and 11, in cube-corner retroreflective sheeting 3, two regions A and B having rotation angle characteristics different from each other by 180 degrees are formed in belt-like shapes and the regions A and B are arranged alternately. A first outer edge of the region A is straight and a second outer edge of the region B is straight and a first outer edge thereof is zigzag. Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com