Control system of sock head sewing machine and sock head sewing machine equipped therewith

A technology for a control system and a sewing machine, which is applied to program-controlled sewing machines, control devices for sewing machines, sewing machine components, etc., can solve the problems of insufficient uniform density of sock toe stitches, inability to control motor speed, and imperfect control systems, etc. The effect of easy control, reduced temperature rise, and even suture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

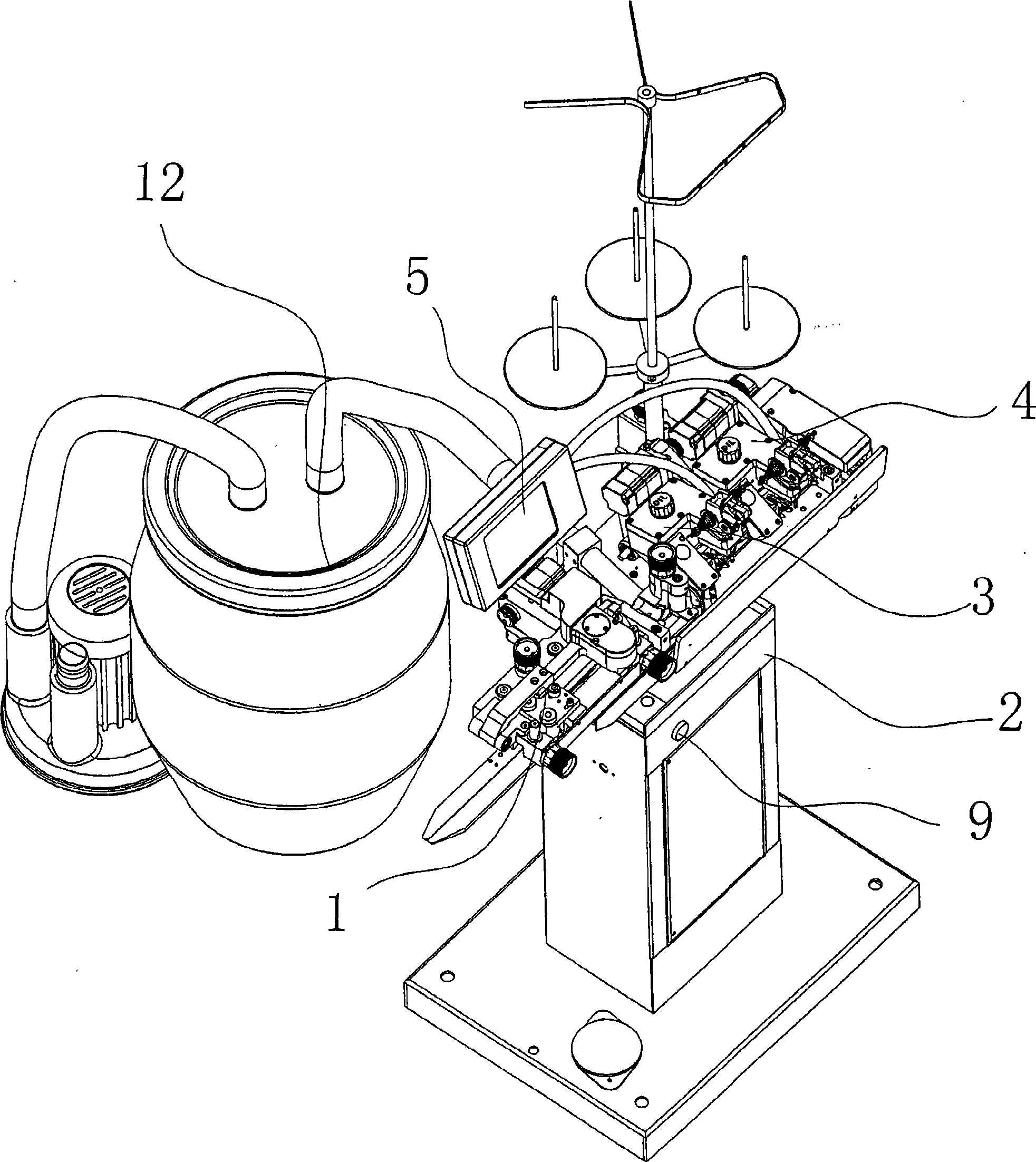

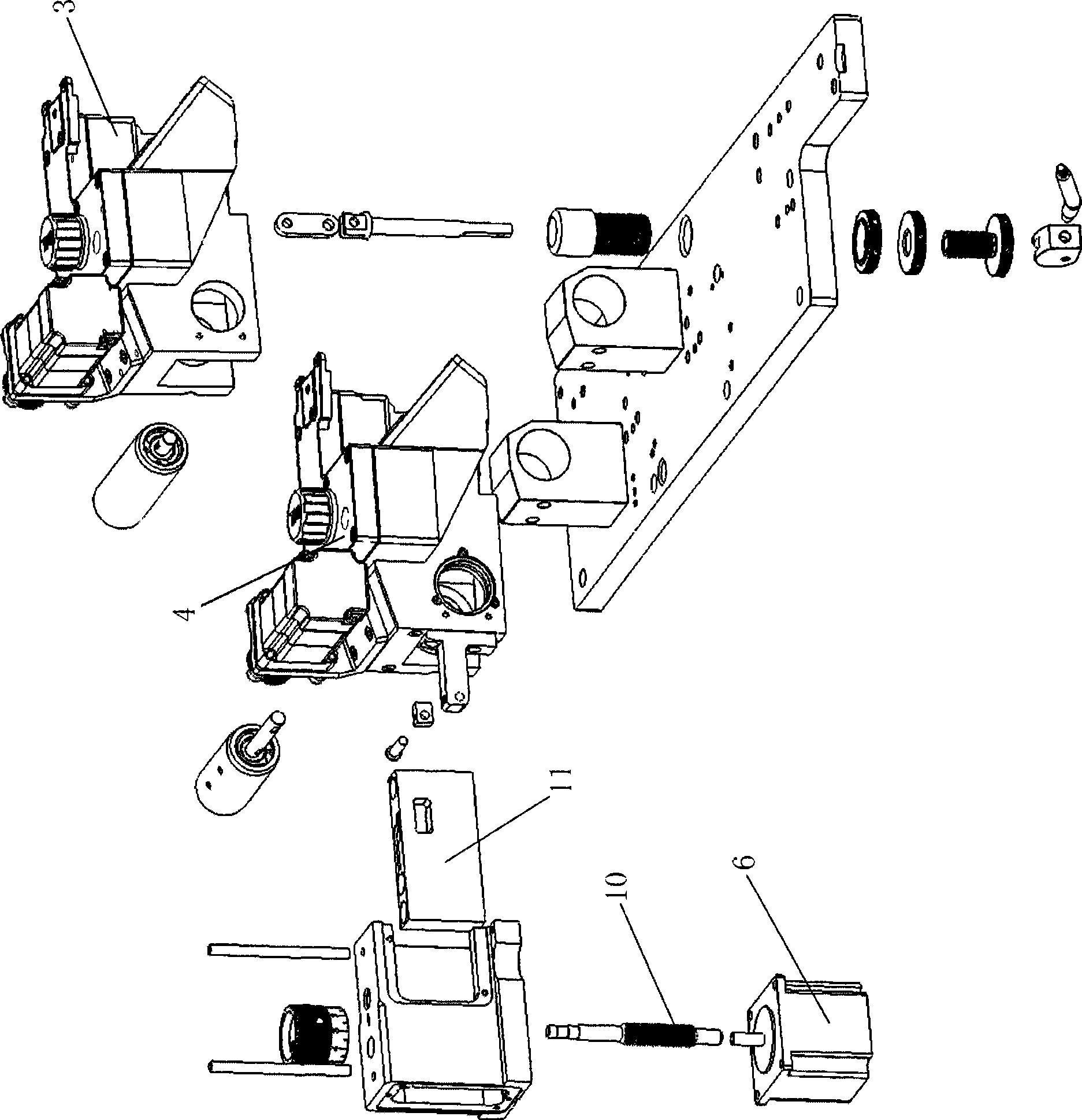

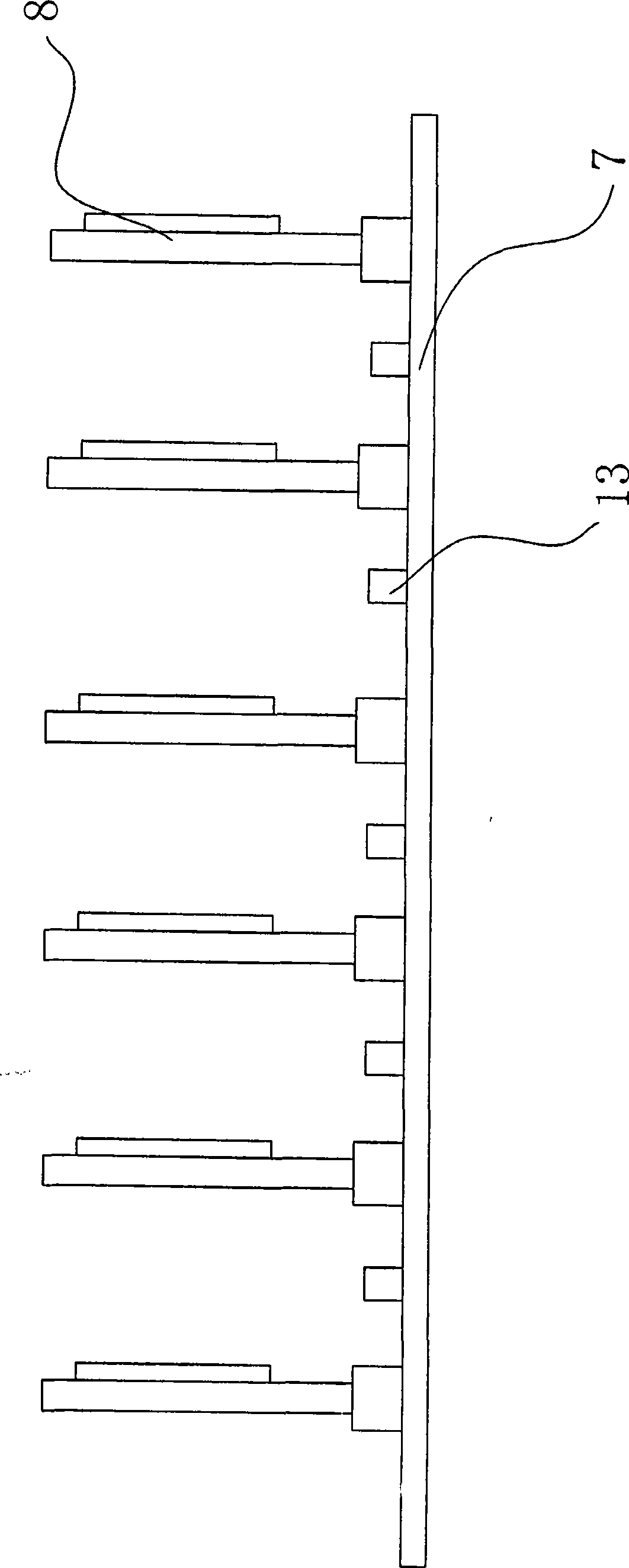

[0021]As shown in the figure, the control system of this sock toe sewing machine includes a power supply part, a motor drive part, a microcomputer control part and a signal detection part. The motor drive part has a feeding device motor drive circuit, a first sewing device The motor drive circuit, the second sewing device motor drive circuit, the conveying device motor drive circuit, the sewing device lifting motor drive circuit, each motor drive circuit is connected with the motors on each device, and the microcomputer control part includes a touch screen or a keyboard, and a liquid crystal display and microcomputer, each of the described motor drive circuits, touch screen or keyboard, liquid crystal display and the described signal detection part is electrically connected with the described microcomputer; each circuit board of each of the described motor drive circuits is connected to the corresponding motor, each Electric connection plug-ins are installed on the circuit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com