Baby Bottle Preparation

a technology for preparing baby bottles and formula, which is applied in the direction of feeding bottles, transportation and packaging, liquid transfer devices, etc., can solve the problems of formula not being cooled sufficiently, and often taking more time to process, etc., to achieve the effect of reducing the need for cooling, reducing the time-consuming process, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

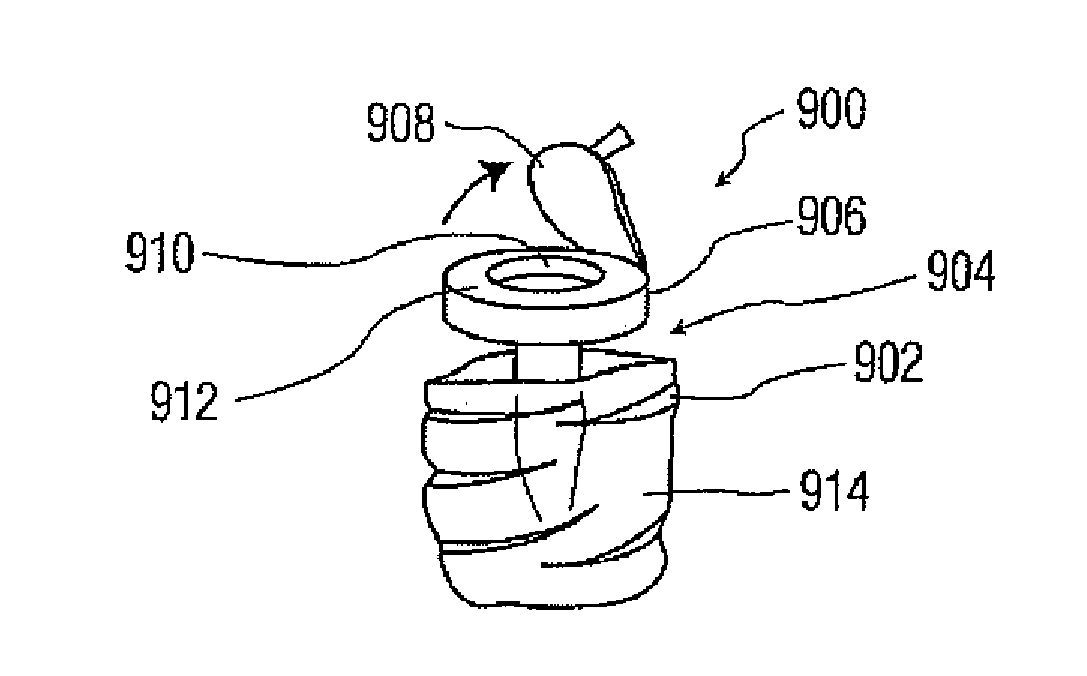

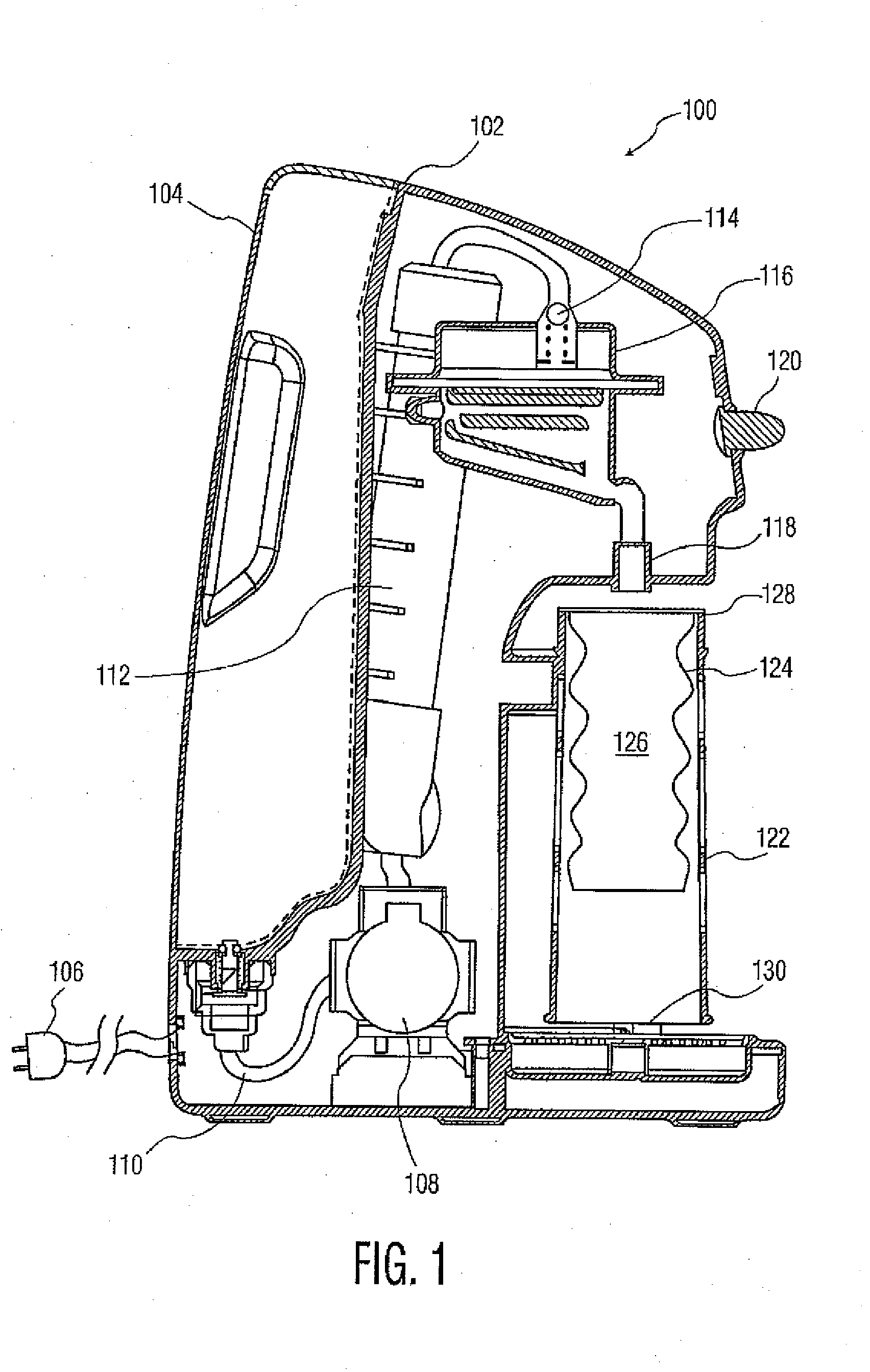

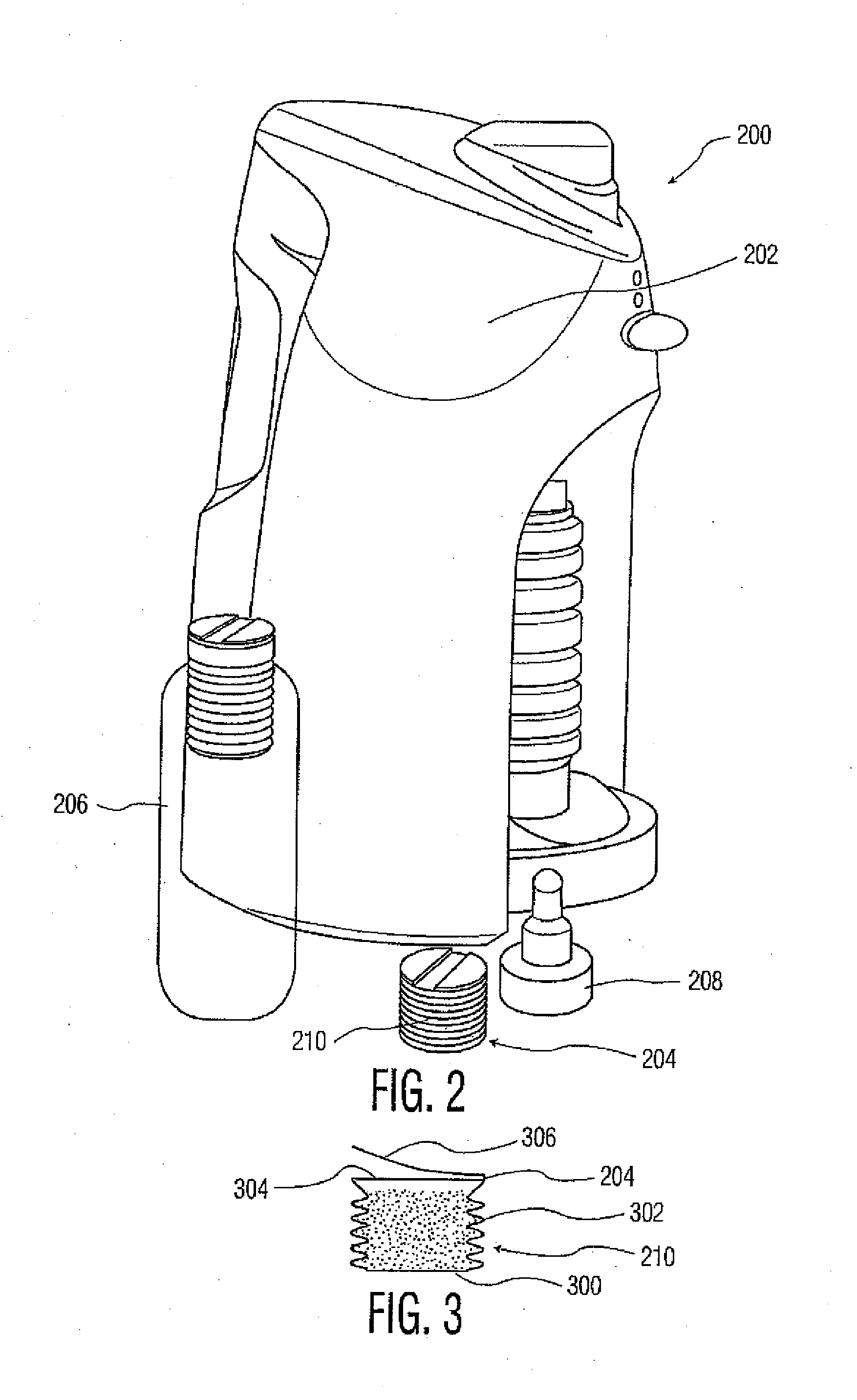

[0044]Advantageous bottle preparation apparatus, systems, kits and associated methods for the use thereof are provided for conveniently and quickly preparing a bottle for feeding an infant in accordance with to the present disclosure. The disclosed apparatus, systems, kits and methods provide a person preparing a bottle of baby formula with the benefit of quickly and accurately dispensing sanitized water, reducing the time required to prepare infant formula-filled baby bottles, and / or providing accurate temperature control to allow immediate consumption without the risk of scalding. Indeed, the disclosed systems and methods for preparing baby bottles improve upon the usage of bottle liners, including with respect to ensuring that an appropriate quantity of formula and is present in the bottle for mixing with and / or dissolving into the sanitized water. Still further, the present disclosure provides reliable and effective apparatus and methods for reducing and / or eliminating the need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com