Burner for a gas combustor and a method of operating the burner thereof

a technology of gas combustor and burner, which is applied in the ignition of turbine/propulsion engine, combustion control, combustion types, etc., can solve the problems of inherently unstable flame, achieve effective gas recirculation, and reduce the risk of fir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]It is known that undesired thermoacoustic oscillations frequently occur in combustors of gas turbines. The term “thermoacoustic oscillations” designates mutually self reinforcing thermal and acoustic disruptions. In the process, high oscillation amplitudes can occur, which can lead to undesired effects, such as to high mechanical loading of the combustor and increased NOx emissions as a result of inhomogeneous combustion. In order to ensure a high output in relation to pulsations and emissions over a wide operating range, further tuning of the fuel distribution and active or passive control of the combustion oscillations may be necessary.

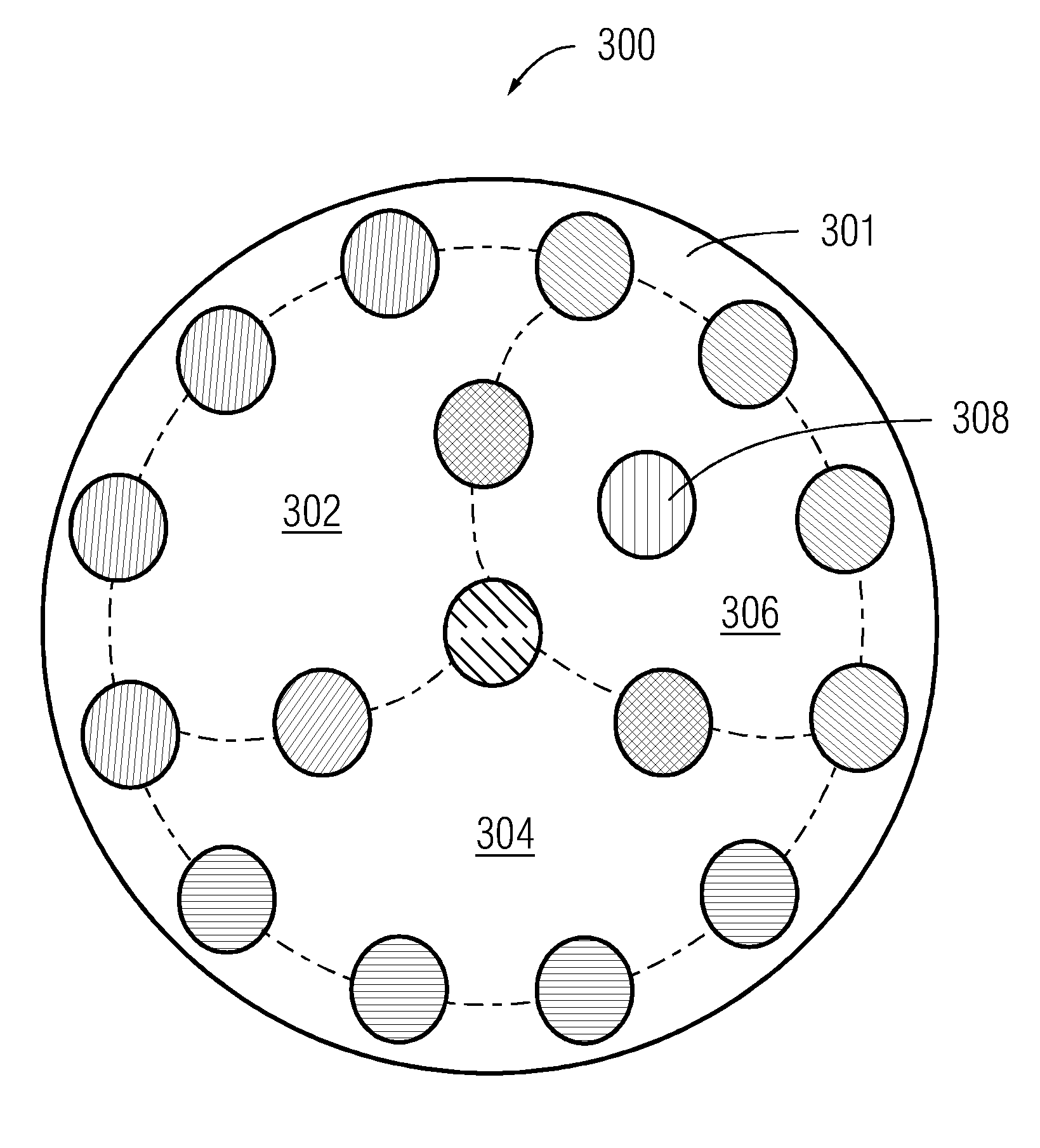

[0023]FIG. 1 illustrates an elliptical burner 100, where inlets are arranged in the front surface area 101 of the burner so as to form two subareas 102 and 104 according to an embodiment of the invention. The inlets 105 along with the common inlets 106 encircle the subarea 102. Likewise, inlets 107 along with the common inlets 106 encircle the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com