Pipeline Pump with Thermal Protection

a pipeline pump and thermal protection technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of high labor intensity, high cost, and high cost of pump body replacement,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

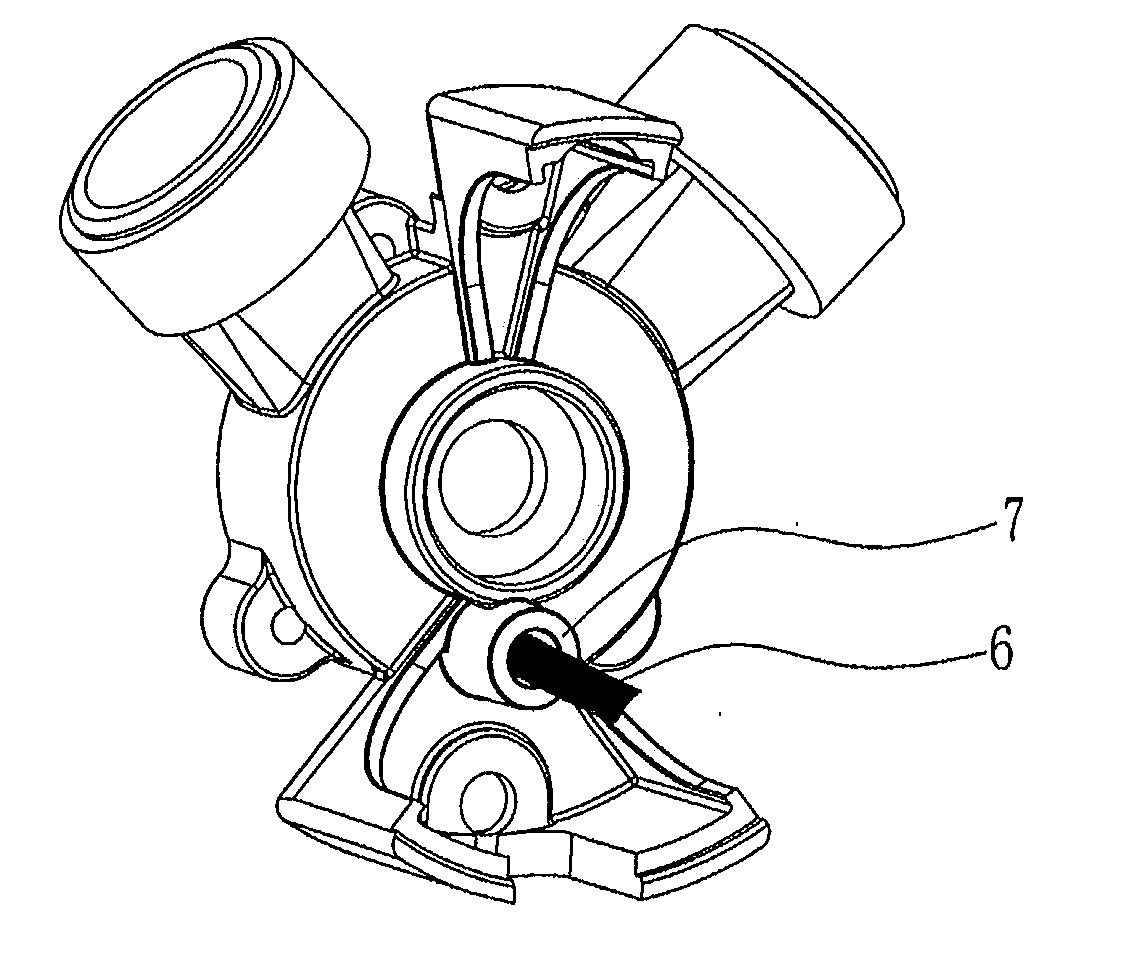

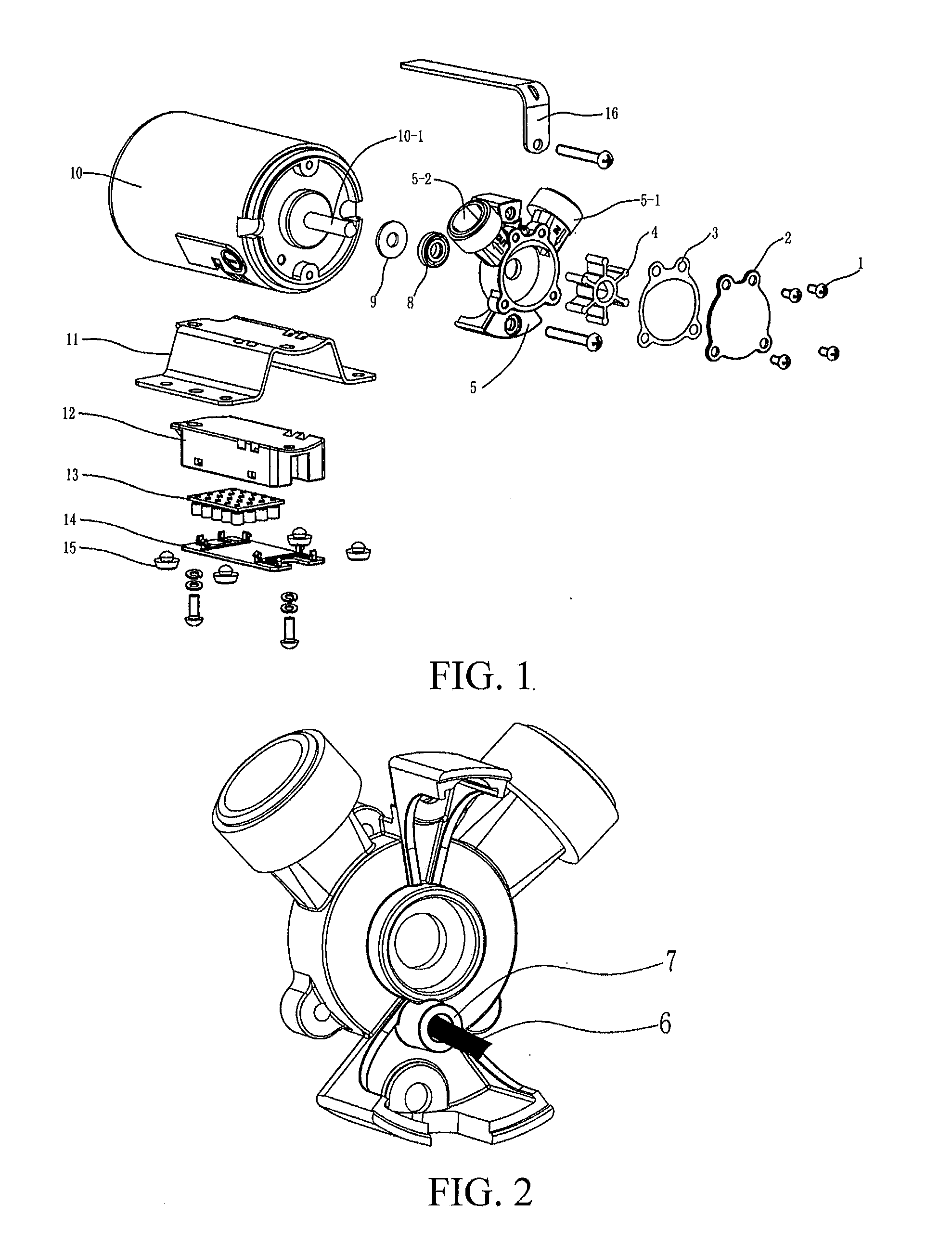

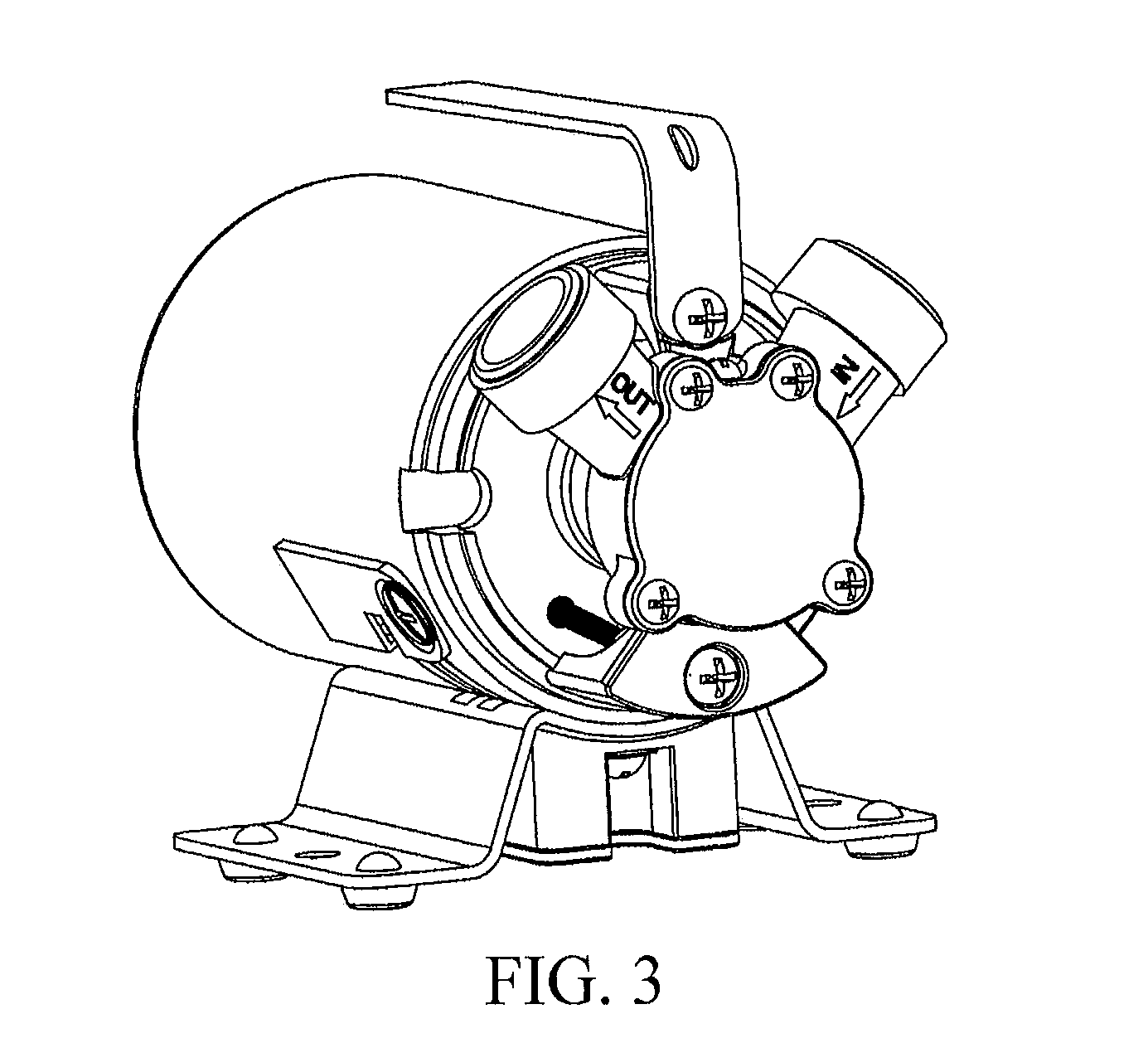

[0035]As shown in FIG. 1, FIG. 2 and FIG. 3, a pipeline pump with thermal protection includes a motor 10, a handle 16 is arranged on the motor 10, a pump body 5 is arranged on a motor shaft 10-1, a water outlet 5-2 and a water inlet 5-1 are arranged on the pump body 5, an impeller 4 is arranged inside the pump body 5, one side of the pump body 5 is fixed and sealed with a pump cover 2, a temperature detecting device 6 is fixed on the pump body 5, and the temperature detecting device 6 is connected to a temperature control circuit board 13; the pump body 5 is made of a copper material, a blind hole 7 is provided on the pump body 5, and the temperature detecting device 6 is sealed on the pump body 5 through a thermally conductive adhesive; a bracket 11 is arranged below the motor 10, a temperature control box 12 is arranged inside the bracket 11, the temperature control circuit board 13 is mounted inside the temperature control box 12, and a temperature control box cover 14 seals the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com