Laminated roll of sealed graphite pouches and methods for making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

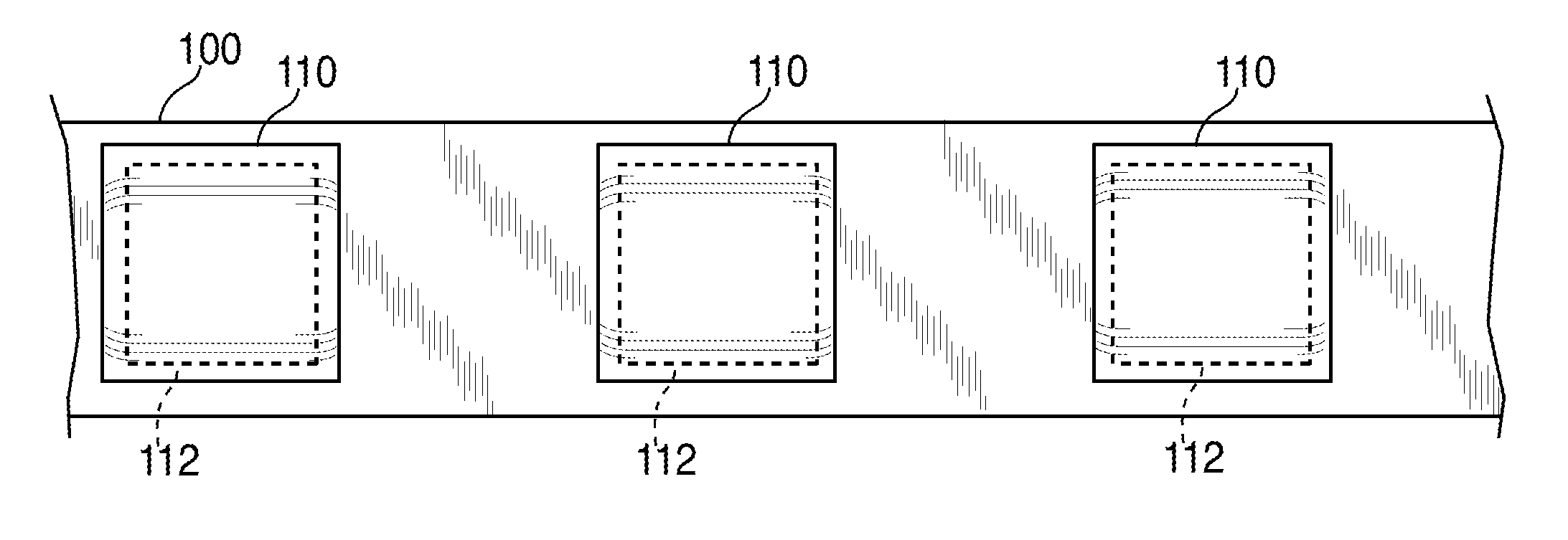

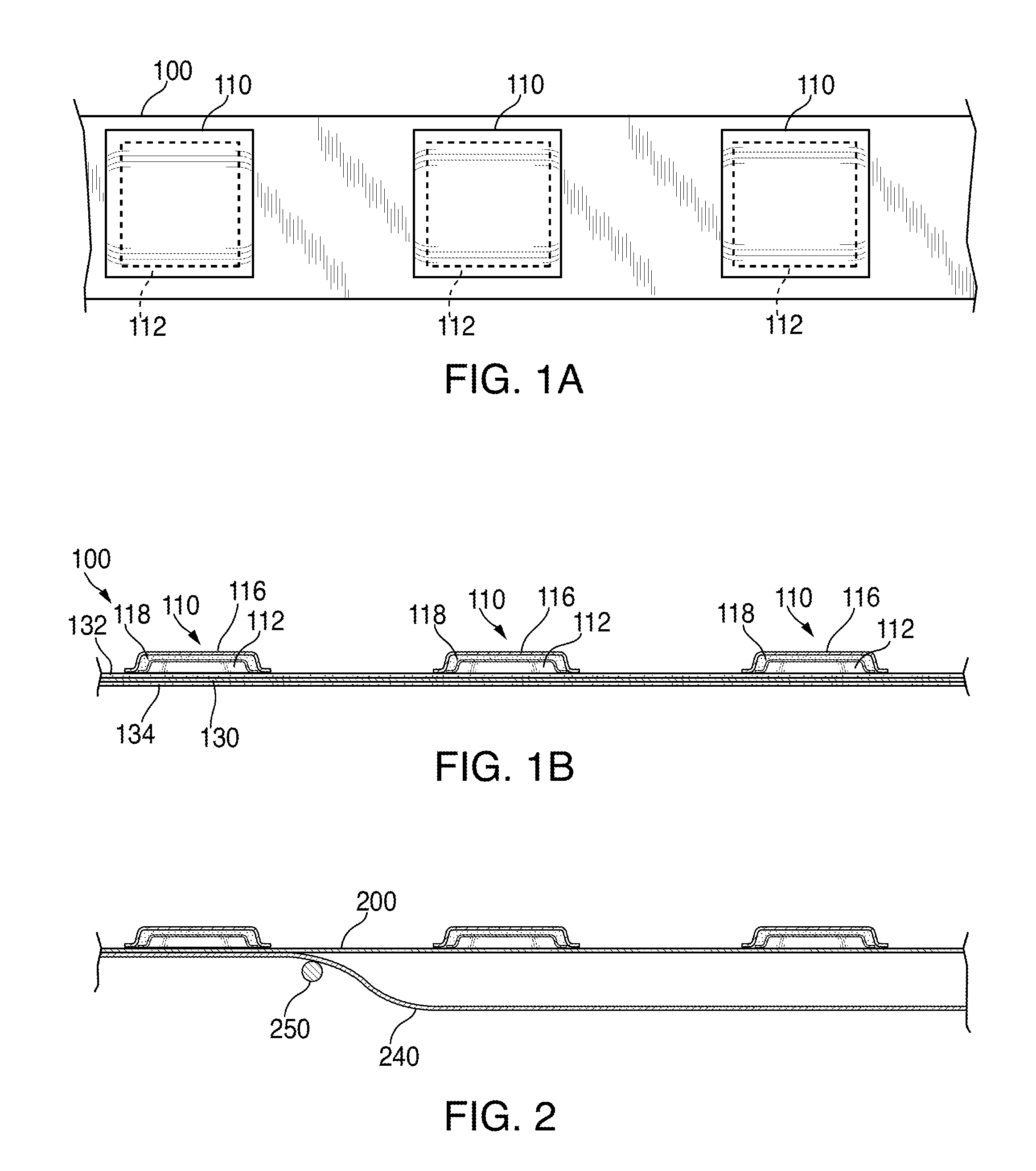

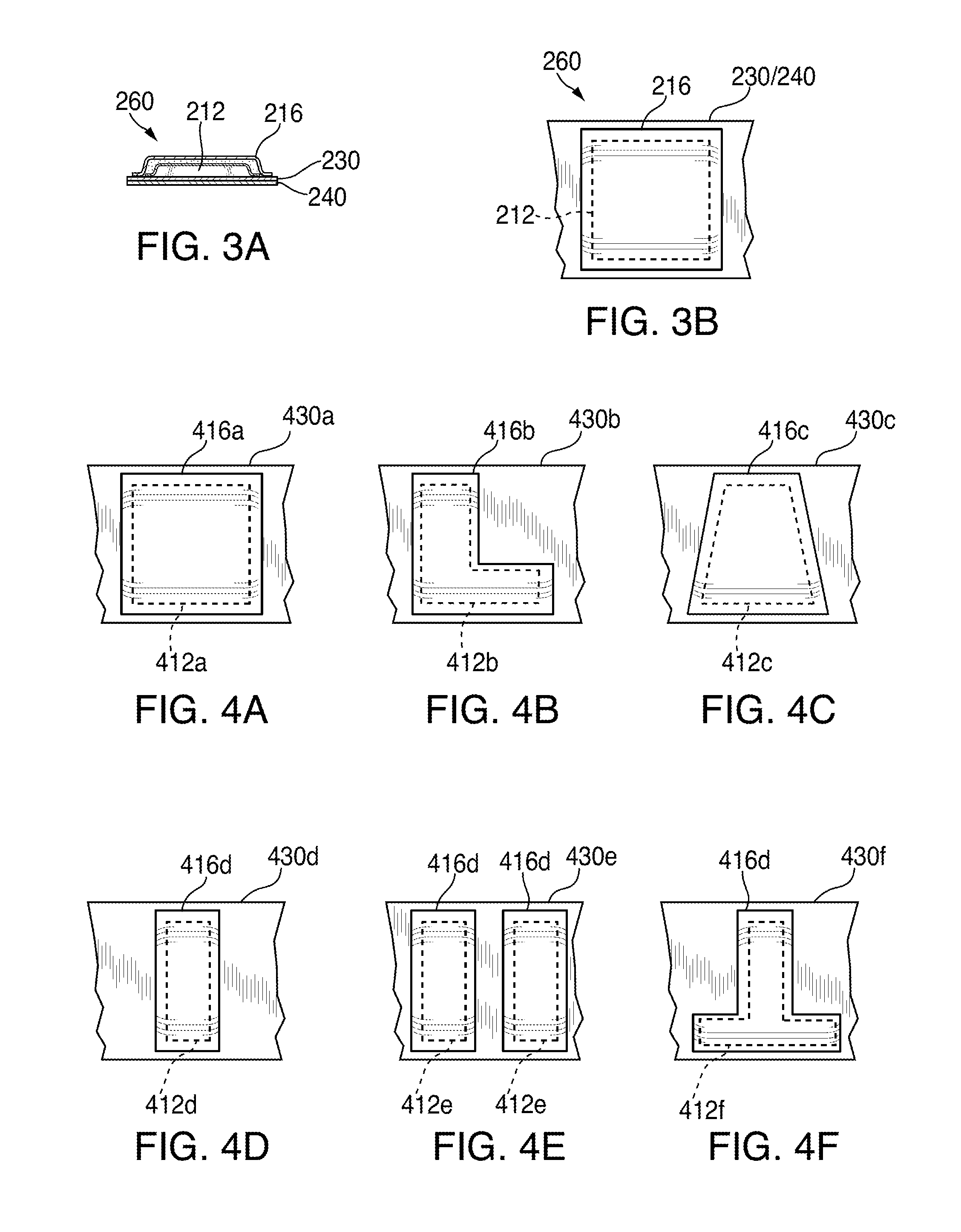

[0015]An electronic device can include components for which dissipation of heat is required. To provide appropriate heat protection for one or more components of the electronic device, one or more heat spreaders can be fixed to those one or more components. For example, one such component that generates heat and typically requires heat dissipation can be a liquid crystal display (LCD). LCDs typically include, among other parts, a light source, light guide, reflective film, polarizers, diffusers, and glass. The heat spreader is typically fixed to the reflective film, which forms the back portion of the LCD—the glass and / or polarizers and diffusers form the front portion. The reflective film, sometimes referred to as an enhanced spectral reflector (ESR), is responsible for reflecting light from the light source through the various components of the LCD. To ensure visual acuity of the LCD is maximized, it is desirable for the reflective film to be undisturbed by any heat spreader fixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com