Ammonia storage control

a technology of ammonia storage and control, which is applied in the direction of electrical control, machines/engines, transportation and packaging, etc., can solve the problems of abrupt and unintentional release of ammonia stored in the scr catalyst to the ambient environment, and the sharp rise in the temperature of exhaust gas, so as to prevent ammonia slip and release, and the conversion of nox is sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

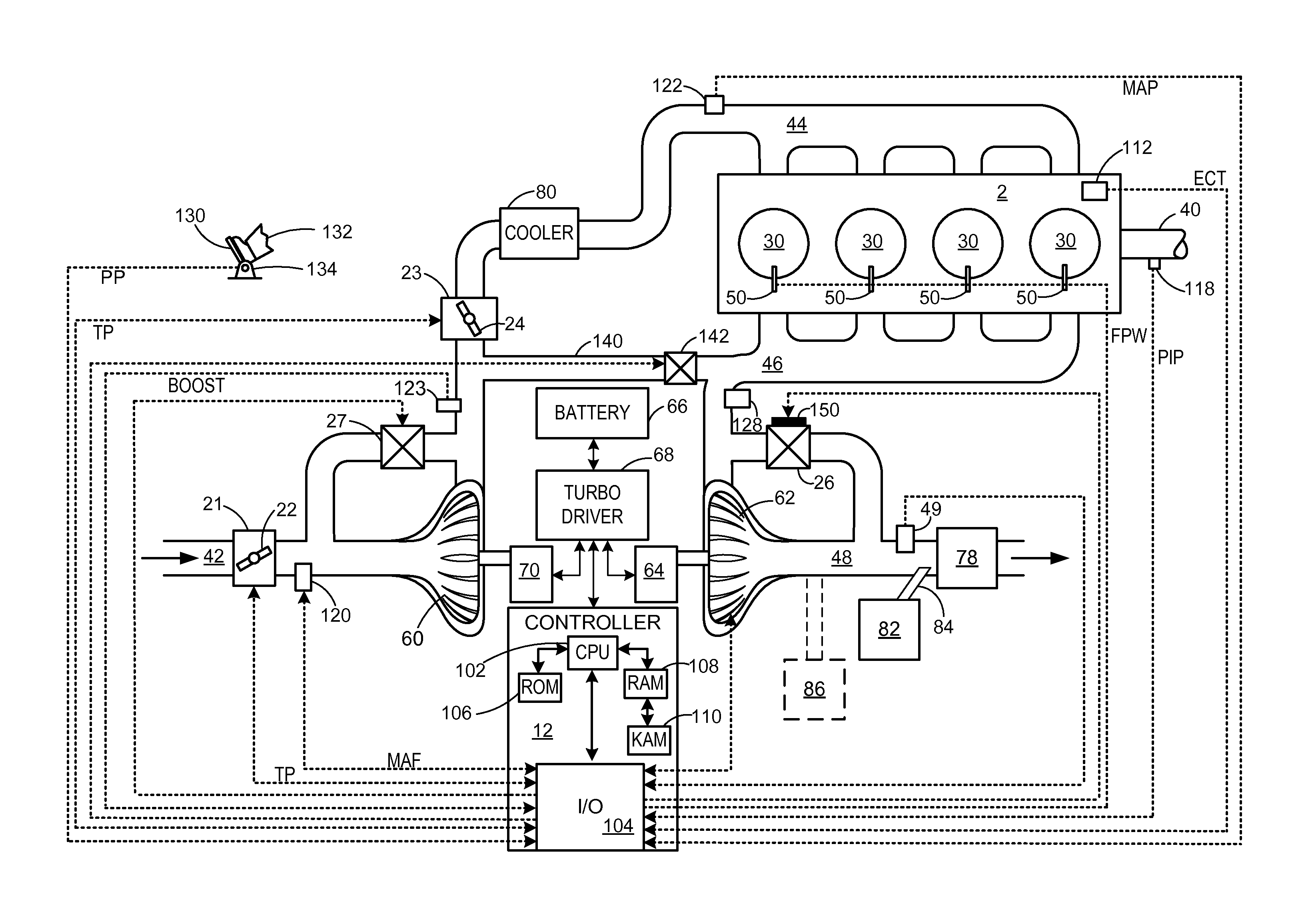

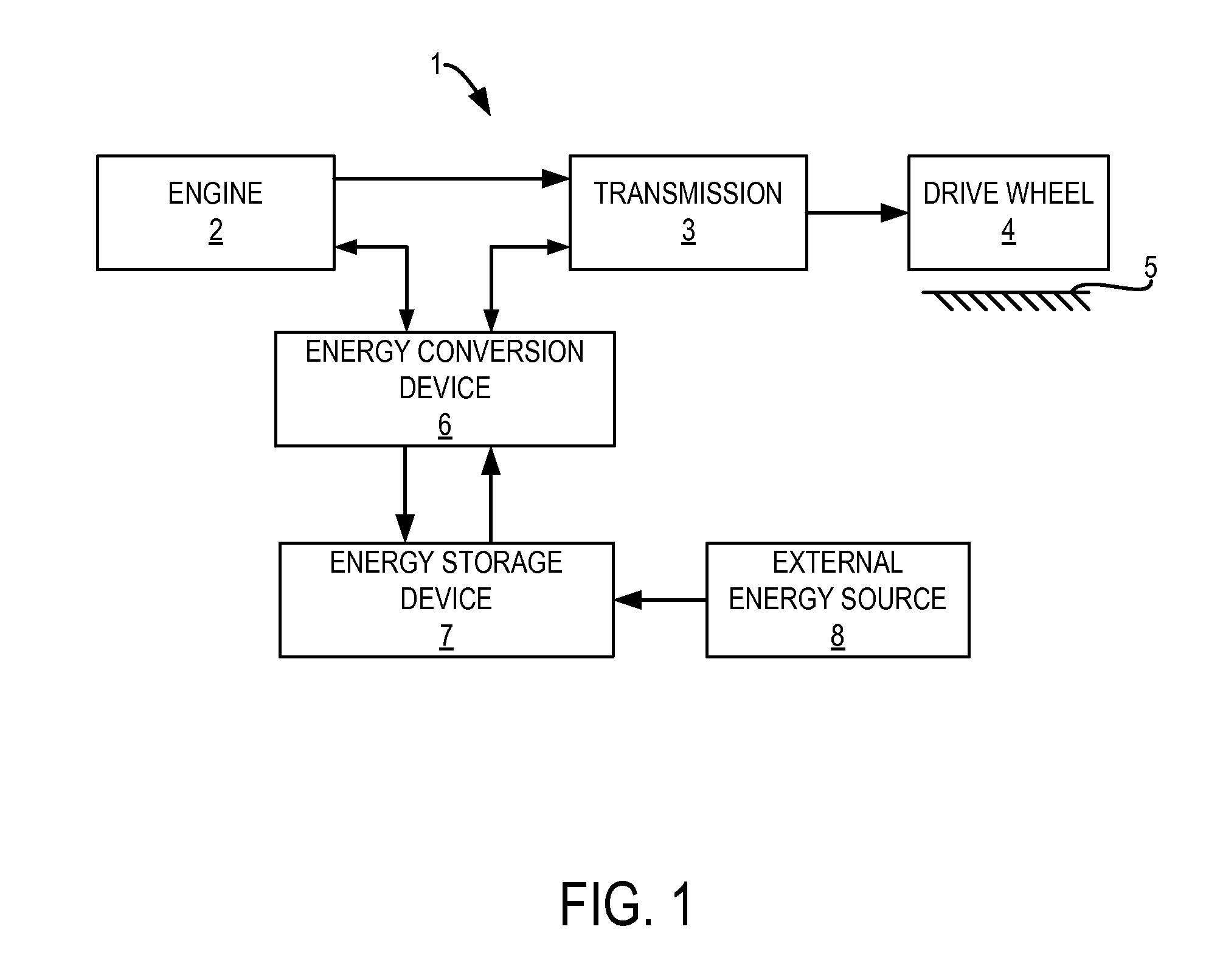

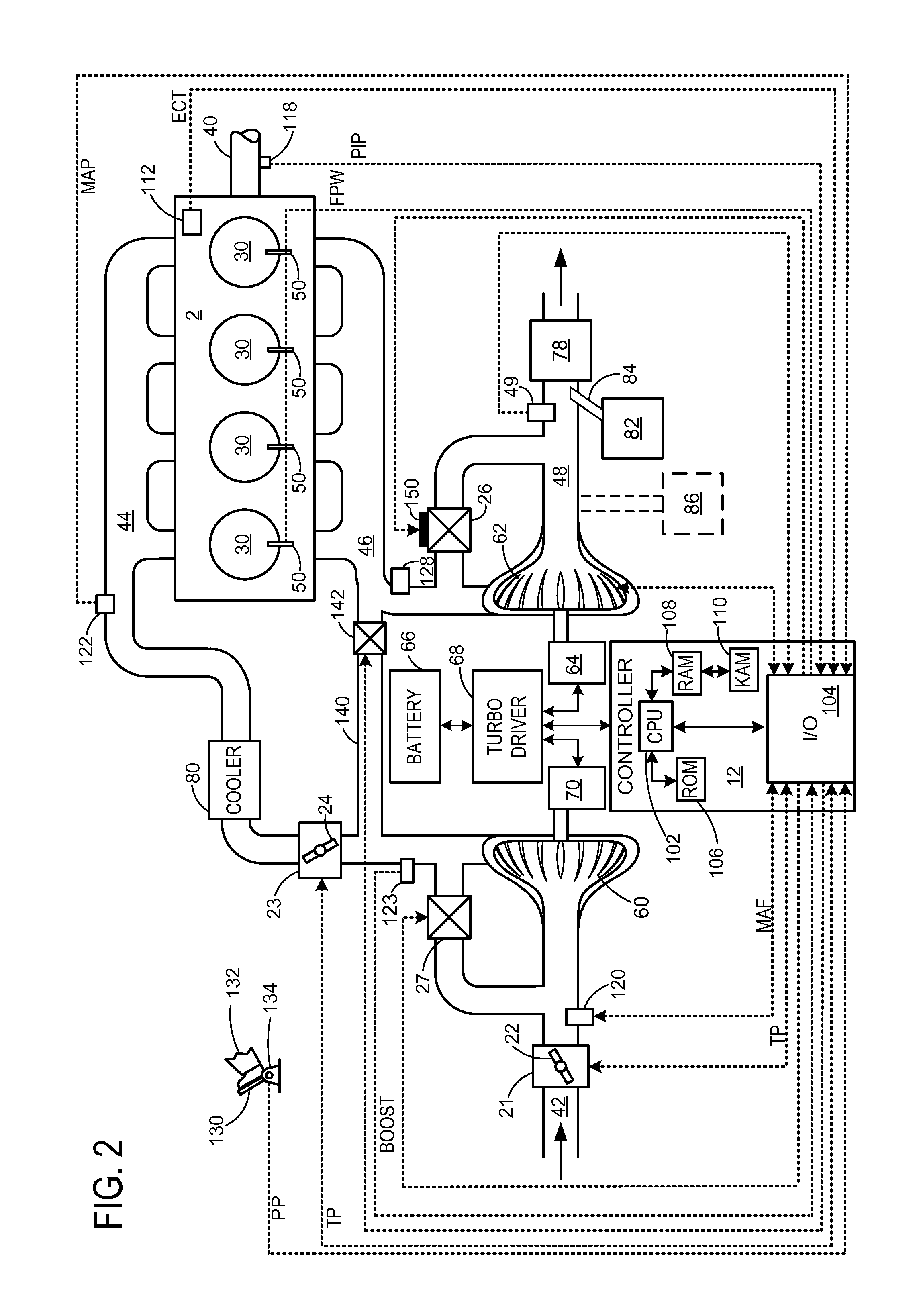

[0015]In some internal combustion engines, urea is introduced upstream of a catalyst and, in the presence of sufficient temperatures, converted to ammonia. The ammonia is utilized as a reducing agent (e.g., reductant) to facilitate the conversion of NOx at the catalyst to other compounds. Several challenges arise in such approaches, however. Because the conversion of urea to ammonia occurs does not occur without sufficient surrounding temperatures, such conversion cannot occur at certain times of engine operation (e.g., a cold start). To compensate, ammonia may be stored in a catalyst and used during these times when conversion is not possible. Accurate control of exhaust gas temperatures, and the temperature of the catalyst, is required, however, to ensure sufficient conversion of NOx and that these temperatures do not exceed a level at which ammonia is released to the ambient environment (e.g., ammonia slip).

[0016]Various methods for controlling ammonia levels stored in a catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com