Rotary shaft wire passage structure

a technology of passage structure and rotary shaft, which is applied in the direction of instruments, doors/window fittings, constructions, etc., can solve the problems of increasing processing time and cost, rotary member (the screen) often failing to provide sufficient assembly space on two sides of the rotary shaft, and difficult to conduct wire through the through hole, etc., to achieve simple and convenient assembly, reduce manufacturing cost, and increase the ratio of good products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

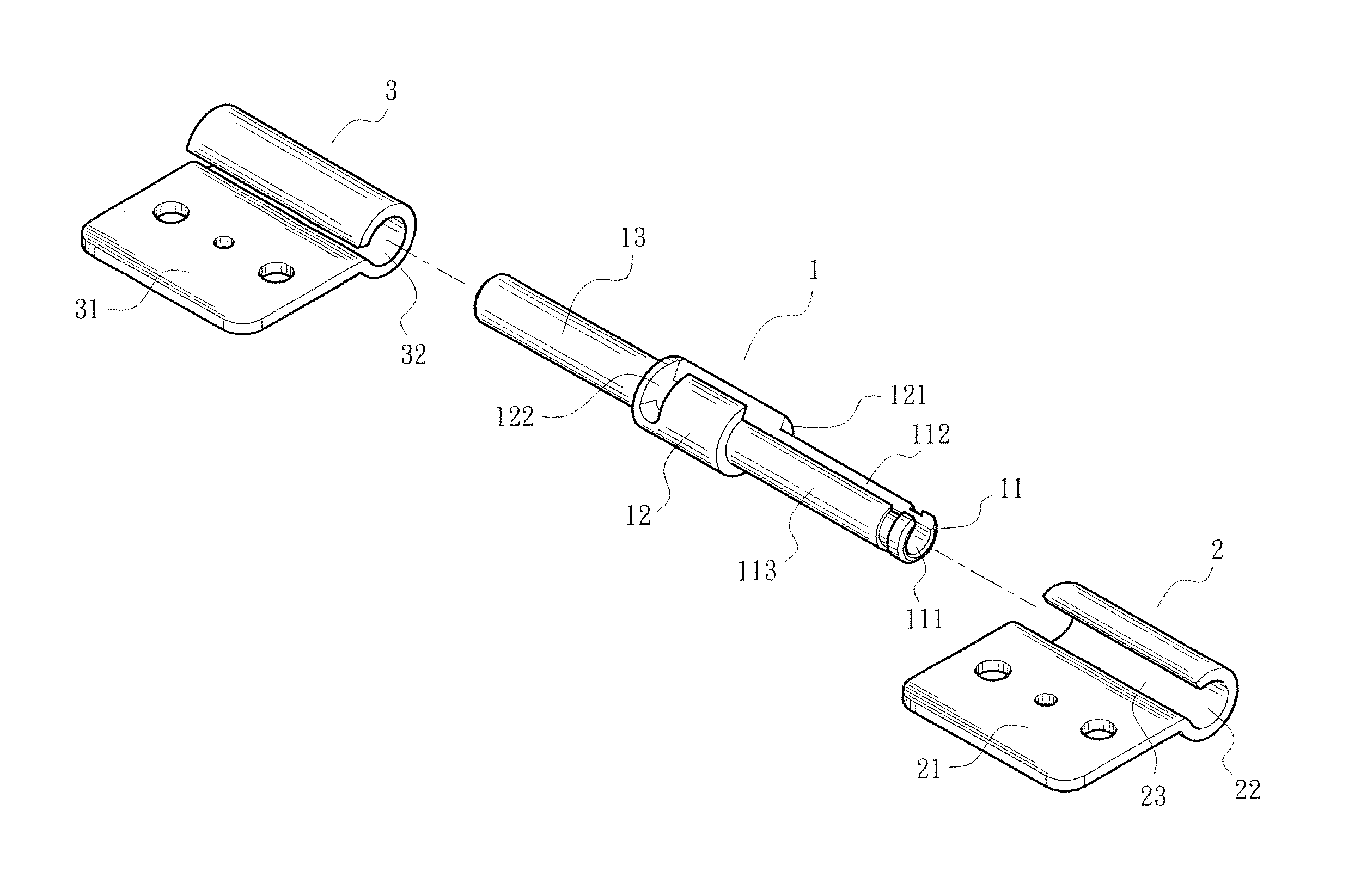

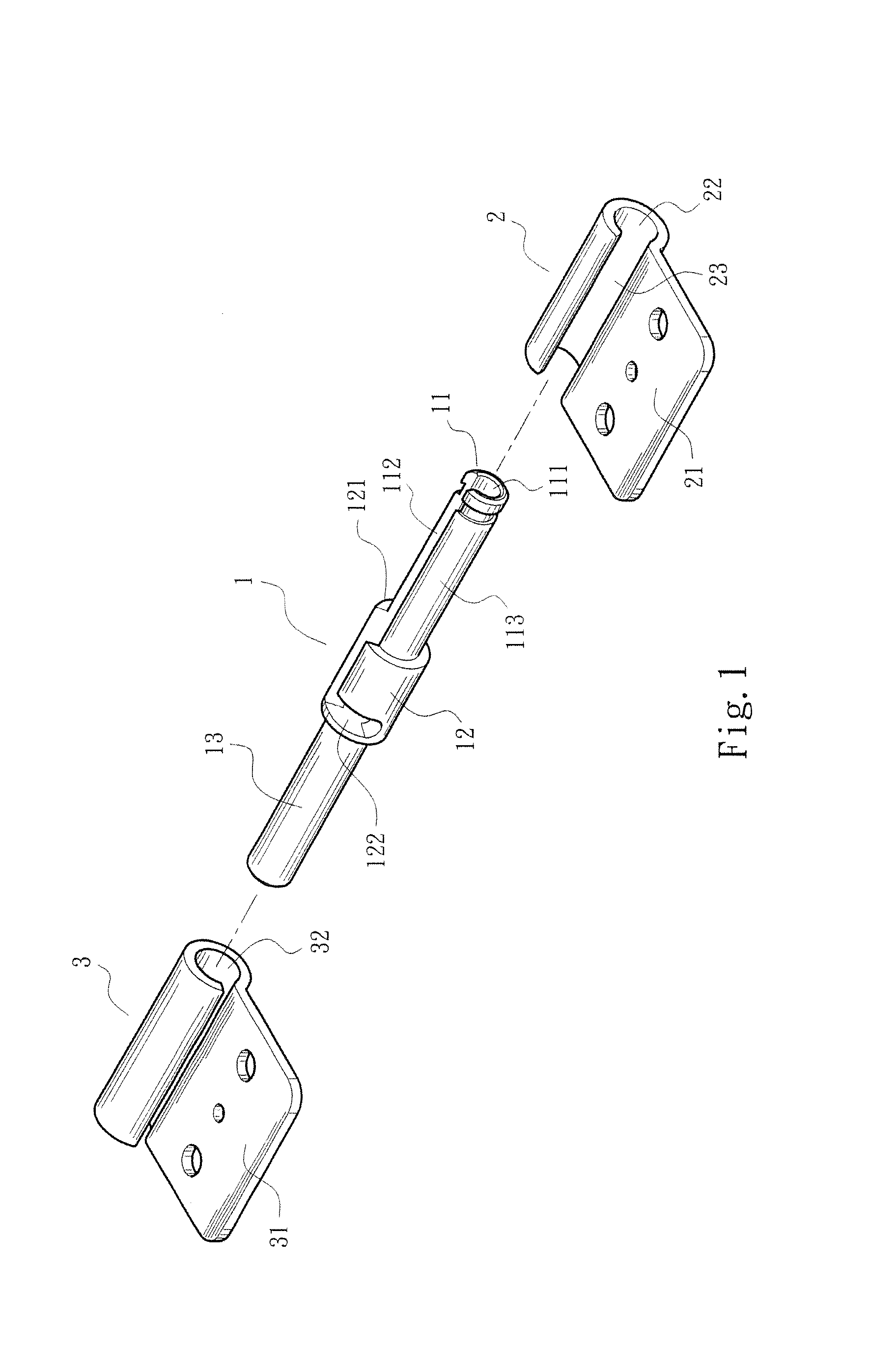

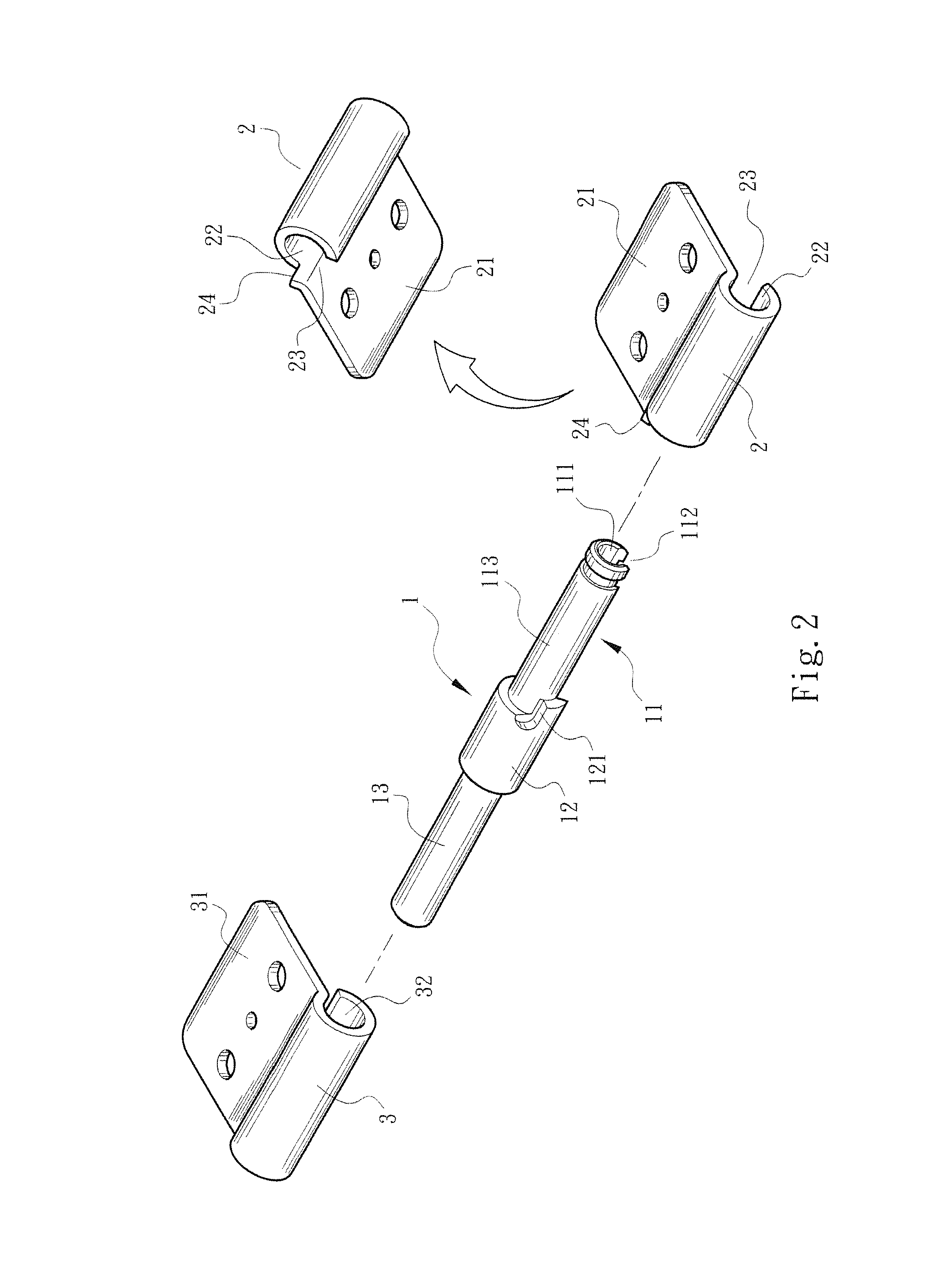

[0031]Please refer to FIGS. 1 and 2. The rotary shaft wire passage structure of the present invention includes a pivot pin 1 and a pivot seat 2. The pivot pin 1 has a pivoted section 11 and an annular raised section 12 disposed at one end of the pivoted section 11. A center of the pivoted section 11 is formed with an axial through hole 111 extending to the annular raised section 12. The through hole 111 is fully in communication with outer side via a split 112. The annular raised section 12 is formed with a transversely extending cut 122 in communication with the split 112. An outer circumference of the pivoted section 11 except the split 112 forms a pivoted surface 113. One side of the annular raised section 12, which side is adjacent to the pivoted section 11, is formed with a protruding stop section 121. The pivot seat 2 has a fixing section 21 and a shaft hole 22 in which the pivoted section 11 can be tightly fitted. One side of the shaft hole 22 is formed with a fissure 23 in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com