Combination Luggage that is Assembled by User

a luggage and user technology, applied in the field of personal items, can solve the problems of increasing production costs, increasing manufacturing costs, and reducing product quality, and achieve the effects of reducing manufacturing costs, reducing production costs, and simplifying the production and assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

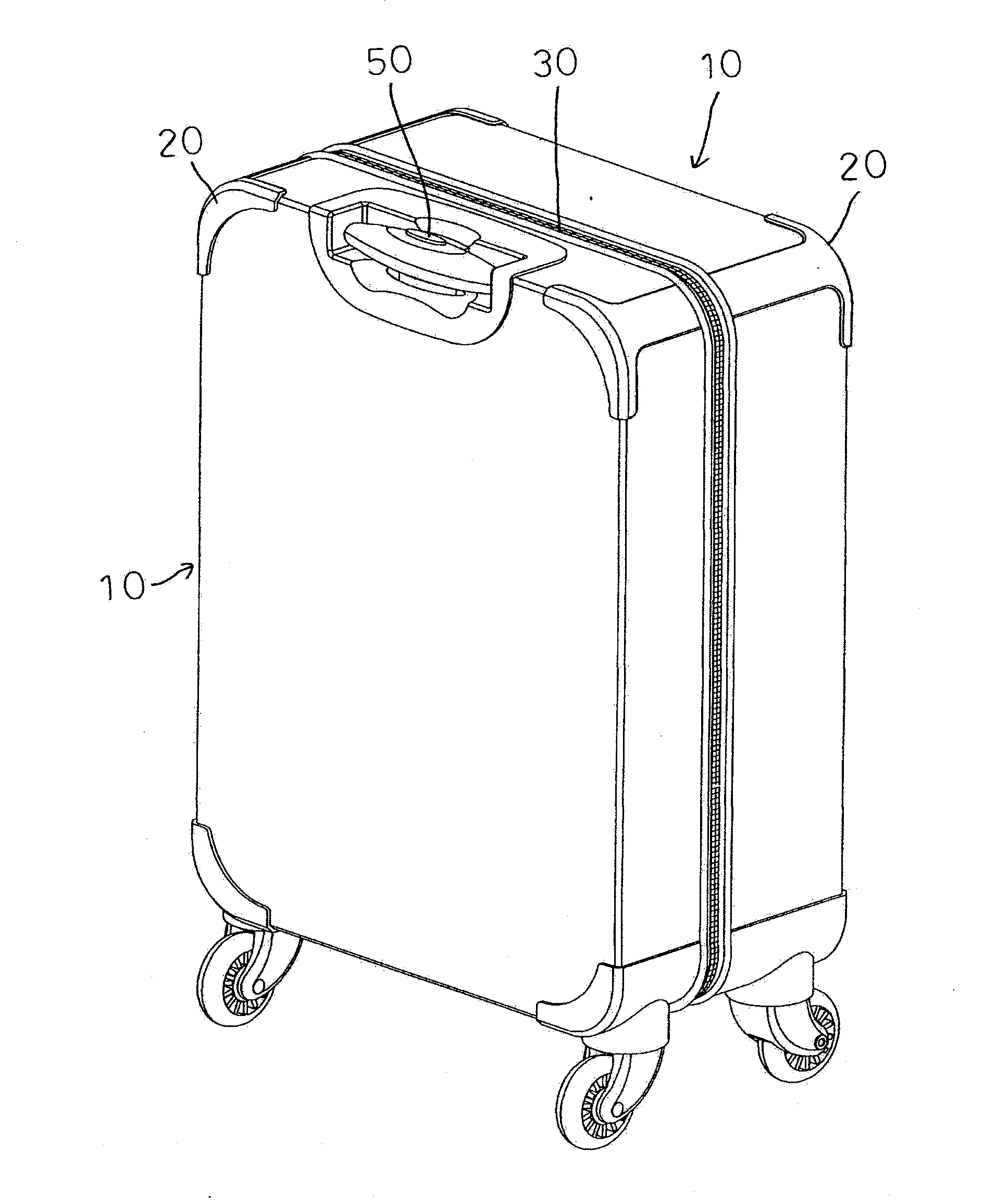

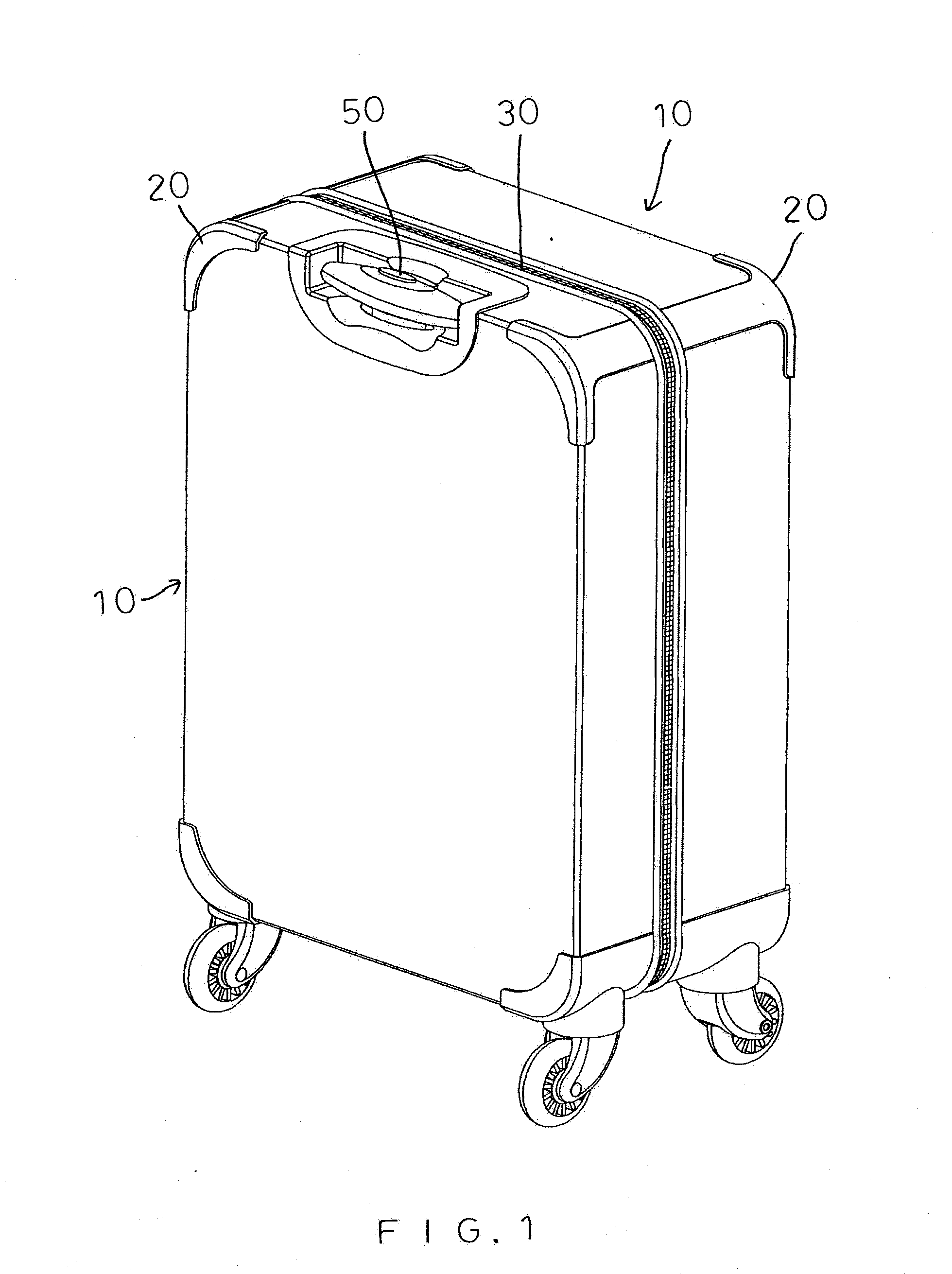

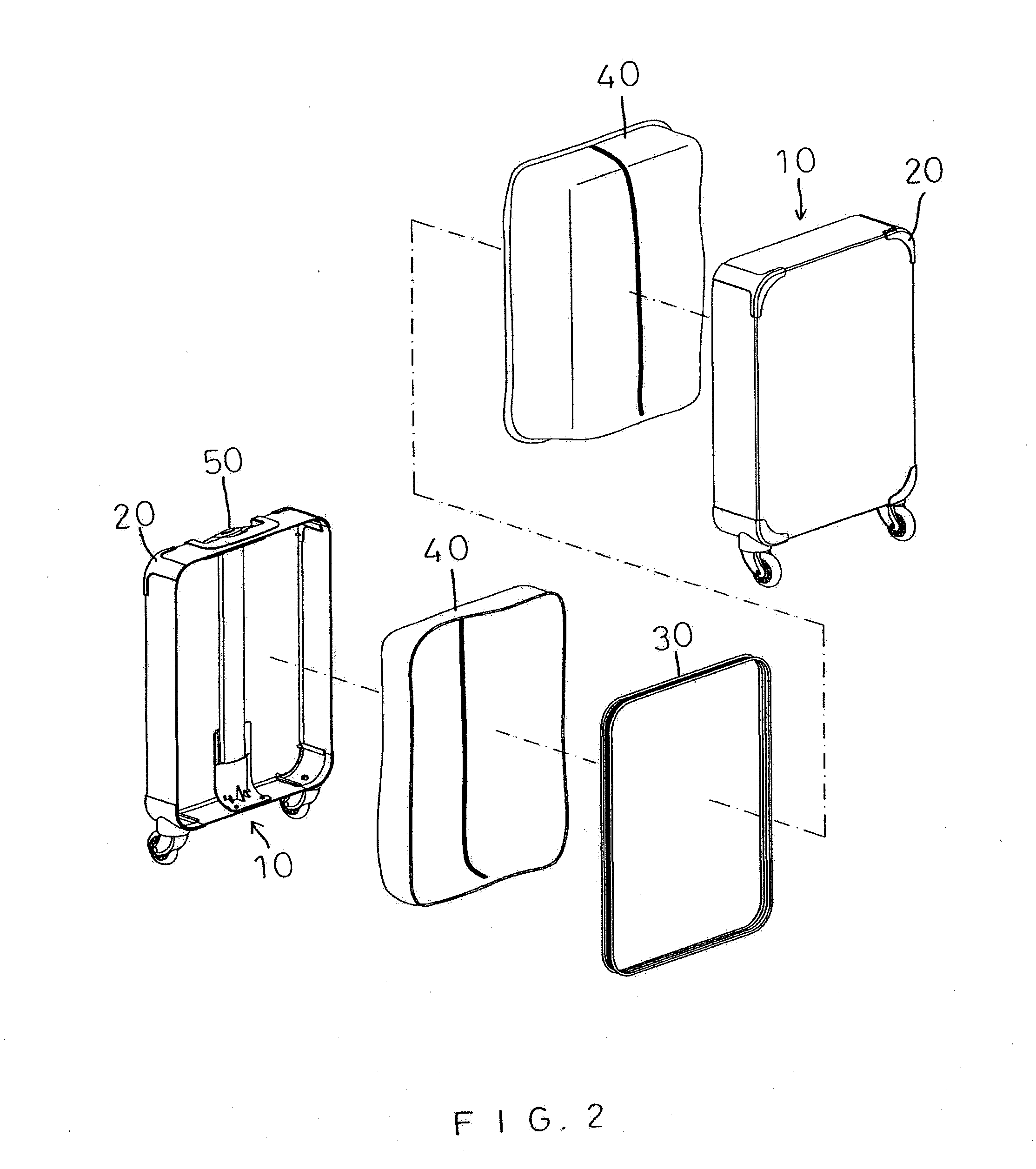

[0018]Referring to FIGS. 1-6, a luggage in accordance with the preferred embodiment of the present invention comprises two foldable shells 10, a connecting member 30 mounted between the foldable shells 10 to connect the foldable shells 10, two linings 40 each mounted in a respective one of the foldable shells 10, and a pull handle 50 mounted on one of the foldable shells 10.

[0019]Each of the foldable shells 10 is made of a sheet plate that is cut and made foldable and bendable by a knife mold. Each of the foldable shells 10 is made of plastic, paper or fiber. Each of the foldable shells 10 includes a main wall 11 and four folding walls 12 connected with the main wall 11. Each of the folding walls 12 of each of the foldable shells 10 is perpendicular to the main wall 11. Each of the folding walls 12 of each of the foldable shells 10 is connected with the main wall 11 by a folding line 13 and is bendable freely relative to the main wall 11. Each of the foldable shells 10 has four corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com