Control mechanism for drawer slide assembly

a control mechanism and slide technology, applied in the field of slide assemblies, can solve the problems of lack of any kind of control over the movement of the drawer, the drawer, the cabinet, and the front of the drawer facia cover, and achieve the effects of reducing noise, limiting linear movement, and reducing nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

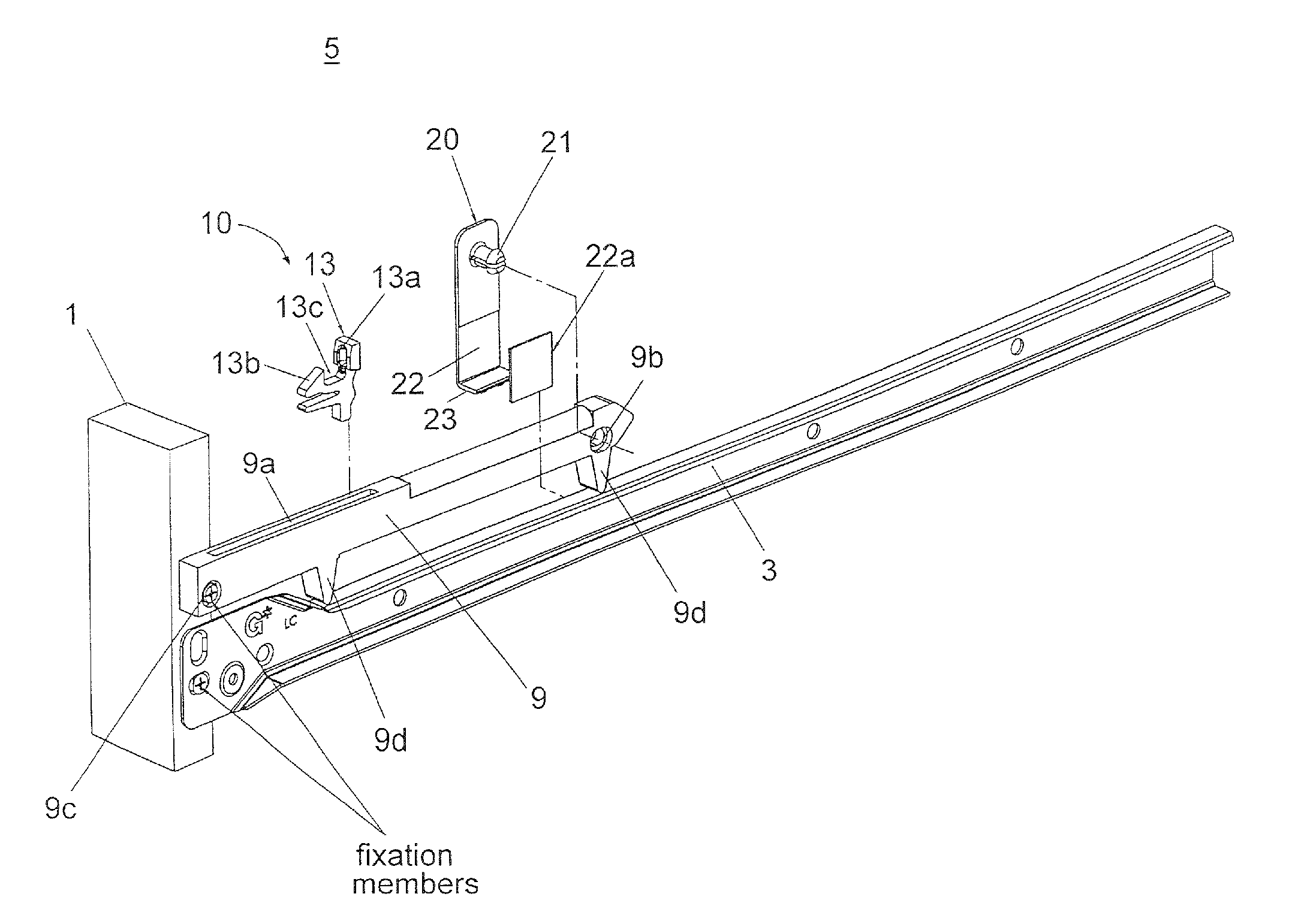

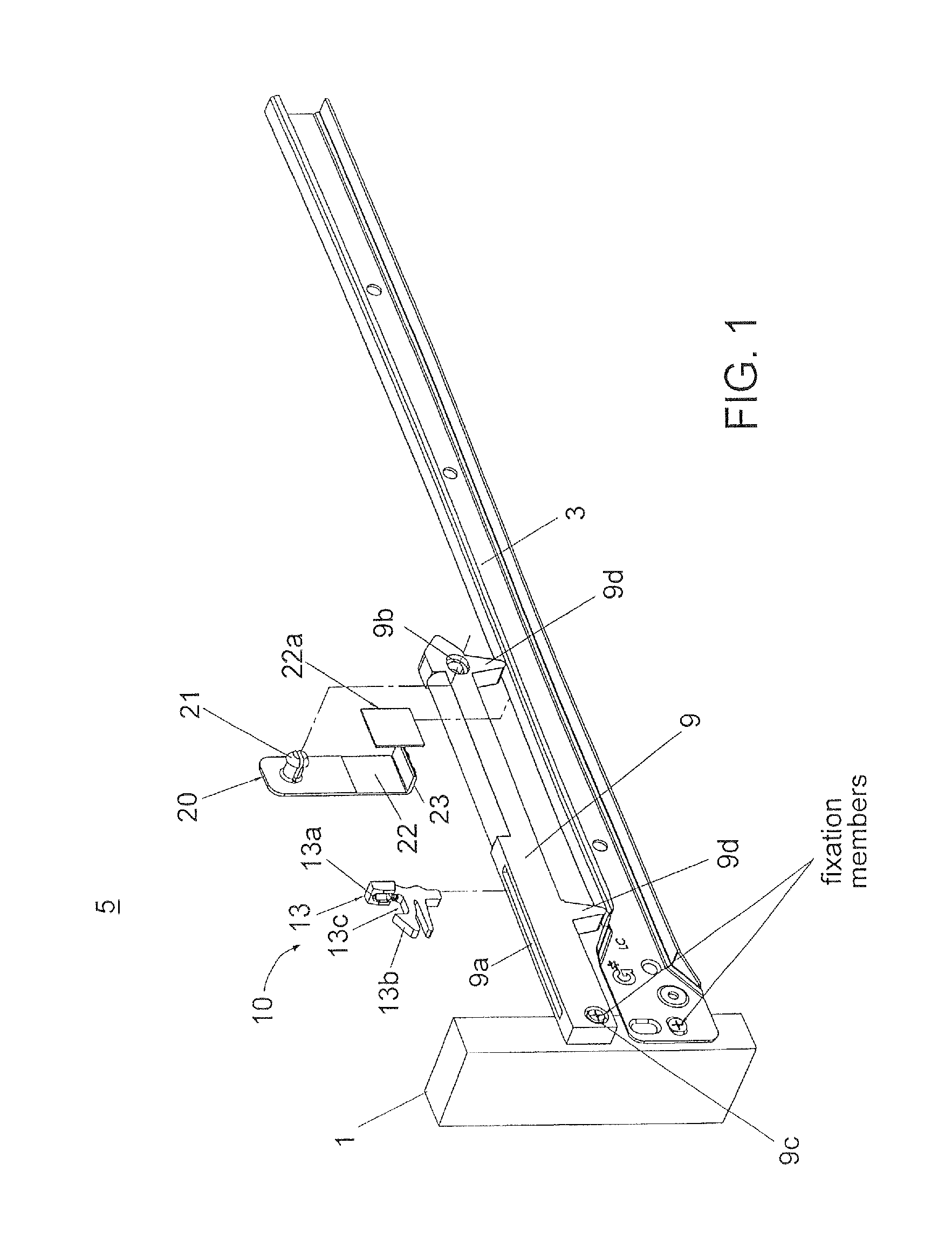

[0023]FIG. 1 is a perspective, left-side view of a drawer slide control mechanism 5 according to one embodiment on the present invention including a shock-absorbing sub-assembly and a combined stabilization bracket 20 for left and right cabinet rail attachment according to one aspect of the present invention (the drawer and drawer rail are removed).

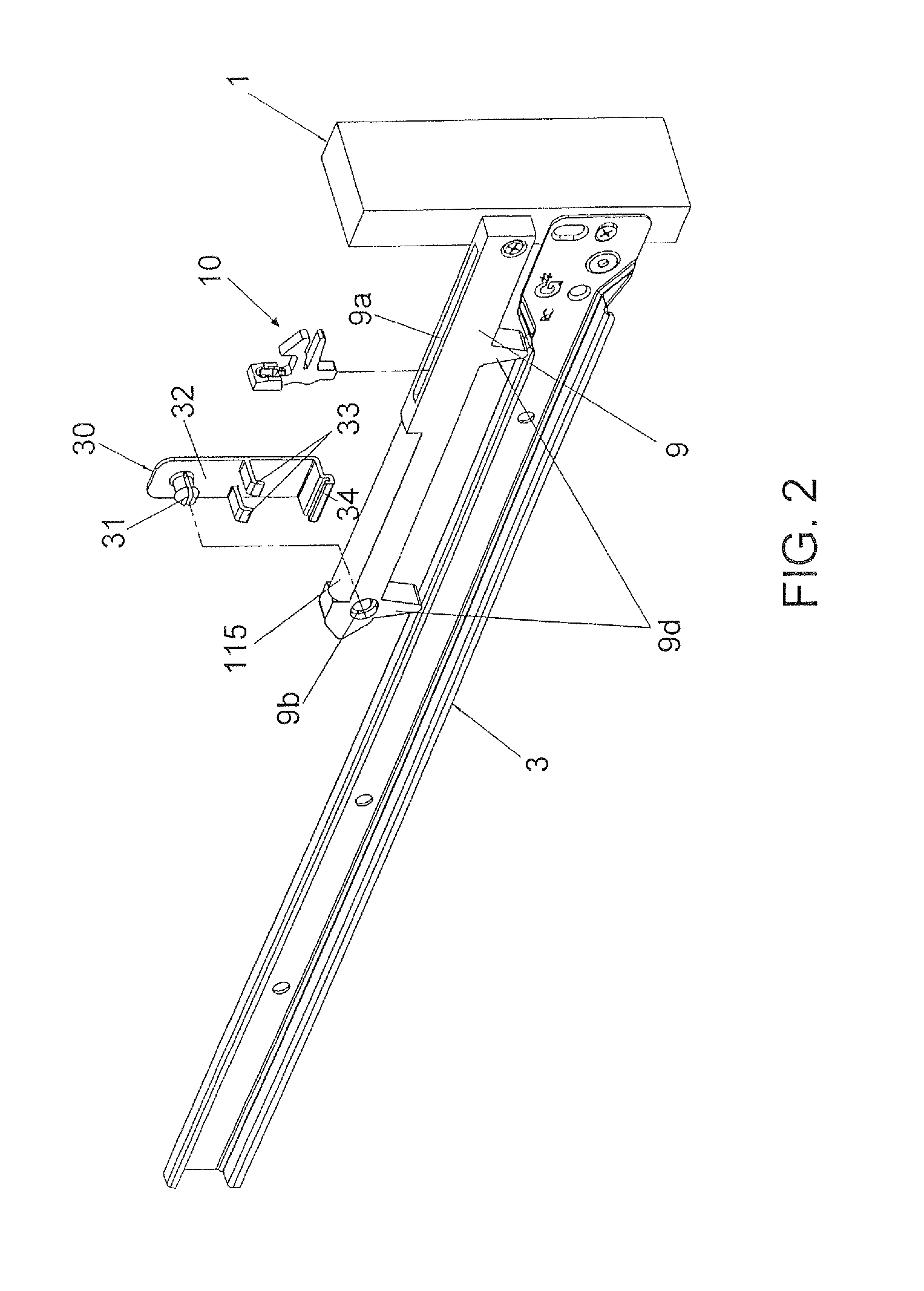

[0024]The control mechanism according to the present invention is designed to function in a similar manner to that which is described in U.S. patent application Ser. No. 13 / 011,269, the entirety of which is incorporated herein by reference. In particular, many of the details of the internal mechanisms and functions that are described in connection with the shock absorbing sub-assembly in the '269 Application are the same in the present invention, and repetitious details are omitted. There are, however, some clear structural differences between the drawer control mechanism of the present invention and that described in the '269 Application...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com