Prefabricated Wall Assembly Having An Insulating Foam Layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

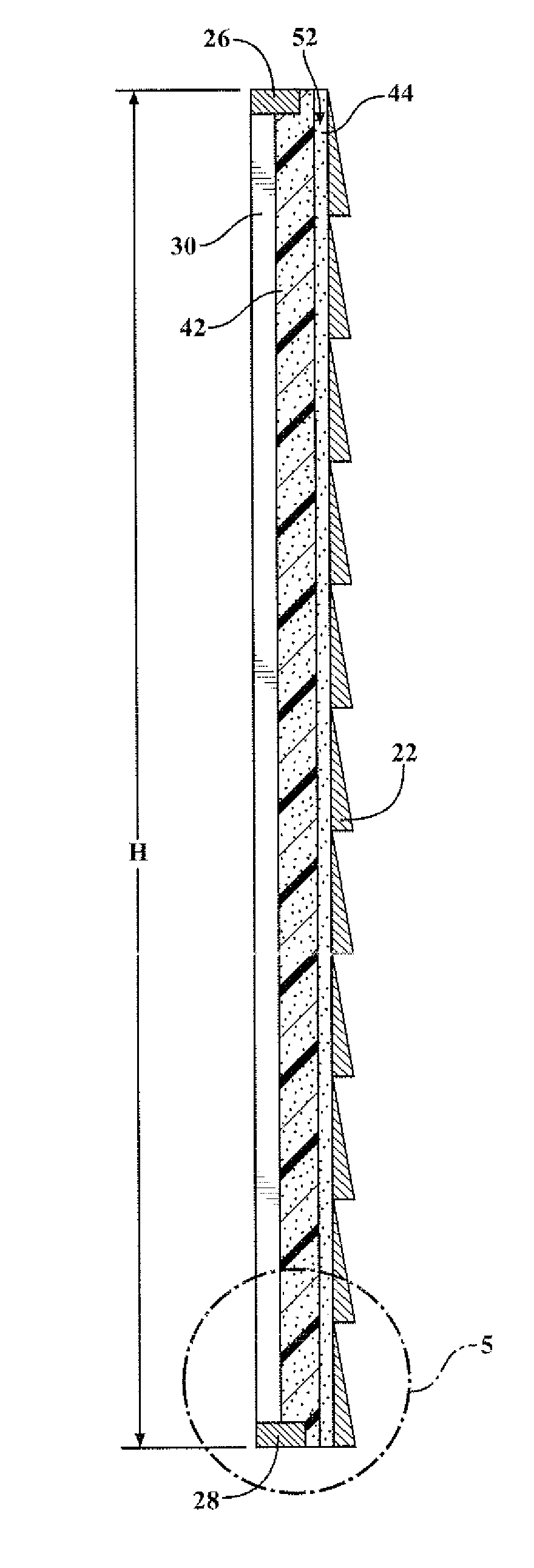

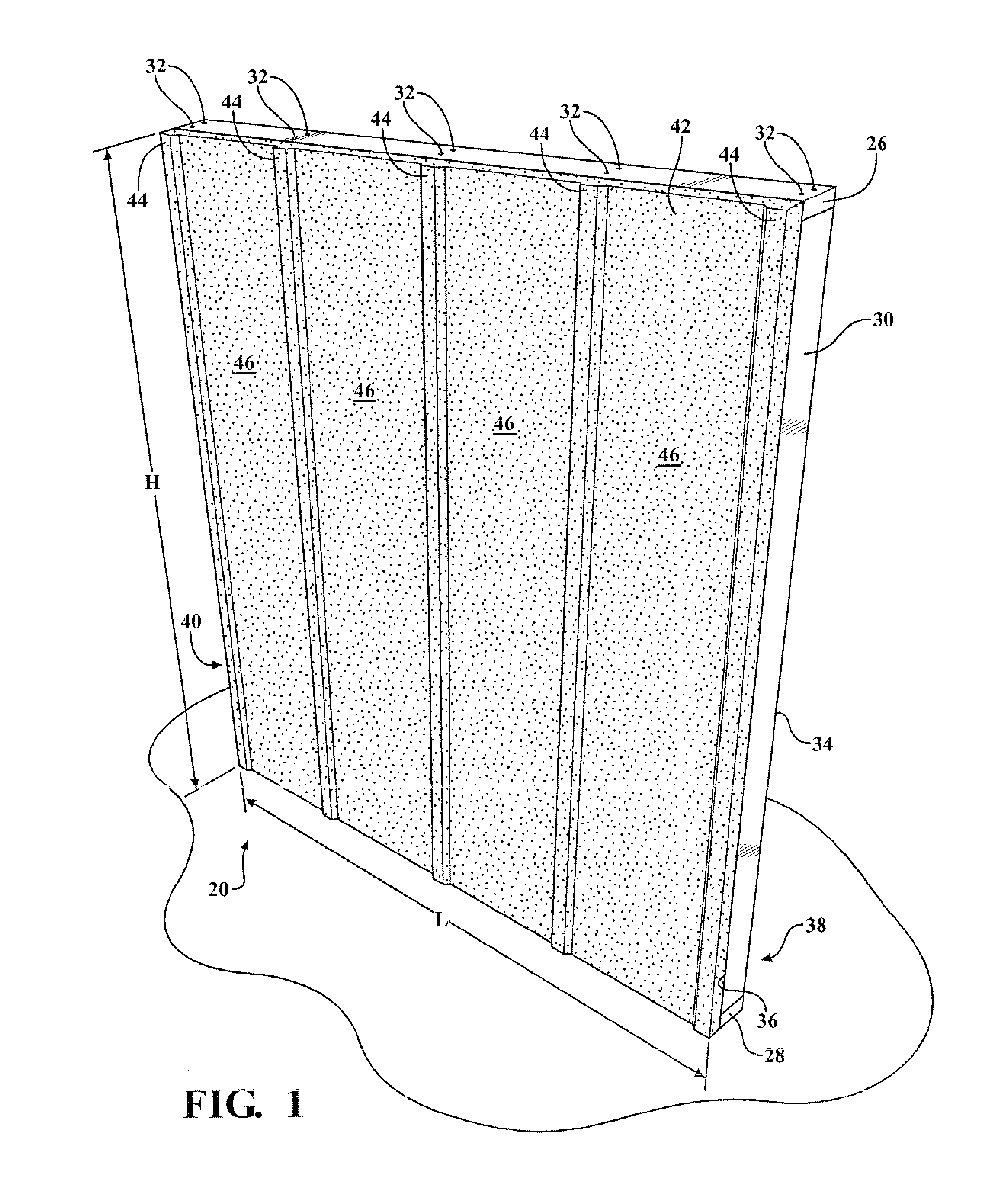

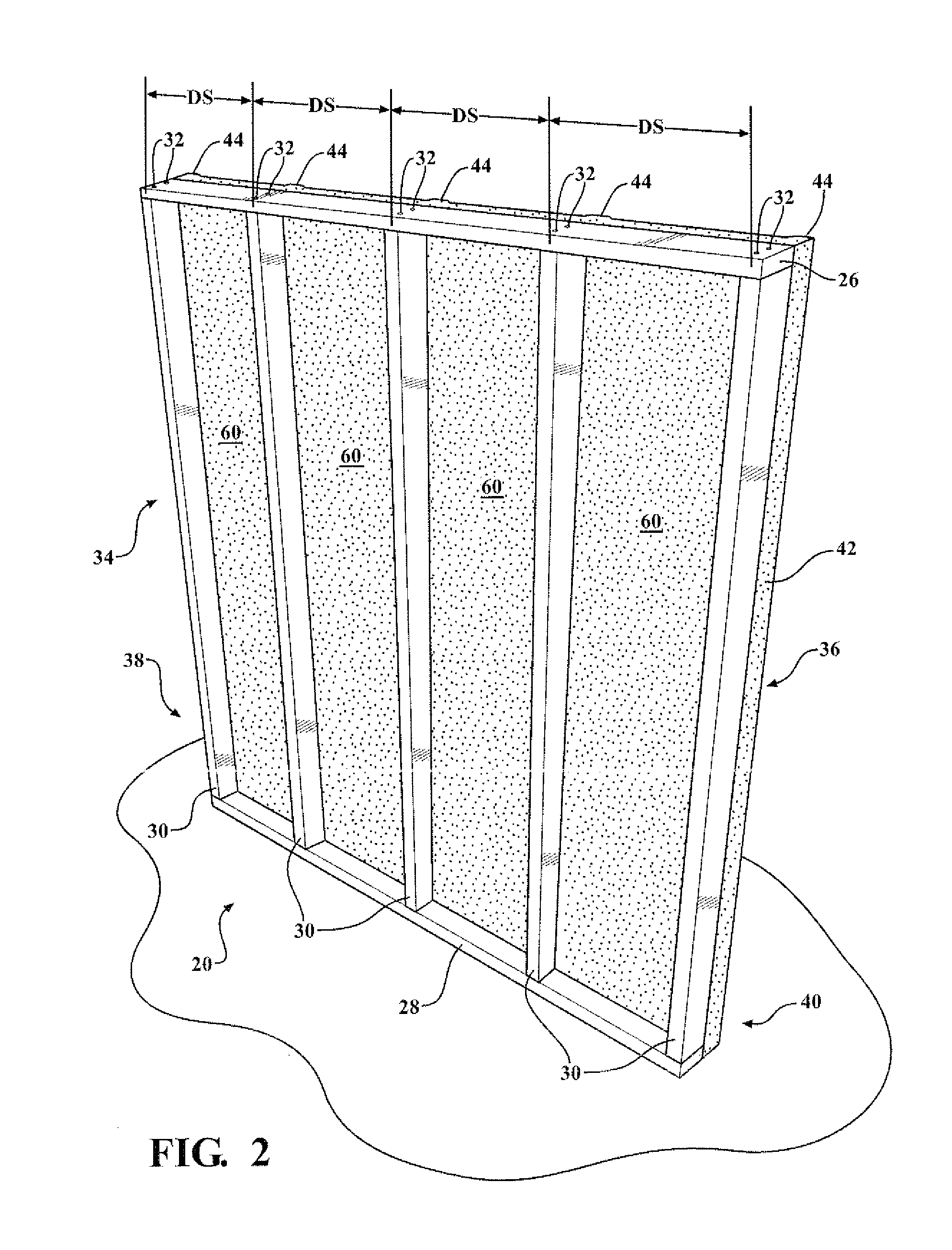

[0028]Referring to the Figures, wherein like numerals indicate corresponding parts throughout the several views, a prefabricated wall assembly is generally shown at 20. The prefabricated wall assembly 20 is for constructing a building, such as a residential building or a commercial building. For example, the prefabricated wall assembly 20 is at least one of a plurality of exterior walls of the building. It is to be appreciated that the prefabricated wall assembly 20 may only be one of the plurality of exterior walls of the building or the prefabricated wall assembly 20 may be all of the plurality of exterior walls of the building. Said differently, the prefabricated wall assembly 20 may be used to construct a single exterior wall of the building.

[0029]Alternatively, multiple prefabricated wall assemblies may be used to construct the exterior walls of building. Said differently, the prefabricated wall assembly 20 may be coupled to another prefabricated wall assembly 20 to define a pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com