Axial Turbomachine Stator with Segmented Inner Shell

a technology of axial turbomachine and inner shell, which is applied in the direction of motors, air transportation, leakage prevention, etc., can solve the problems of increasing the weight of the shell, the shell is subject to frequency excitation, and the inner shell can develop destructive vibrational modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

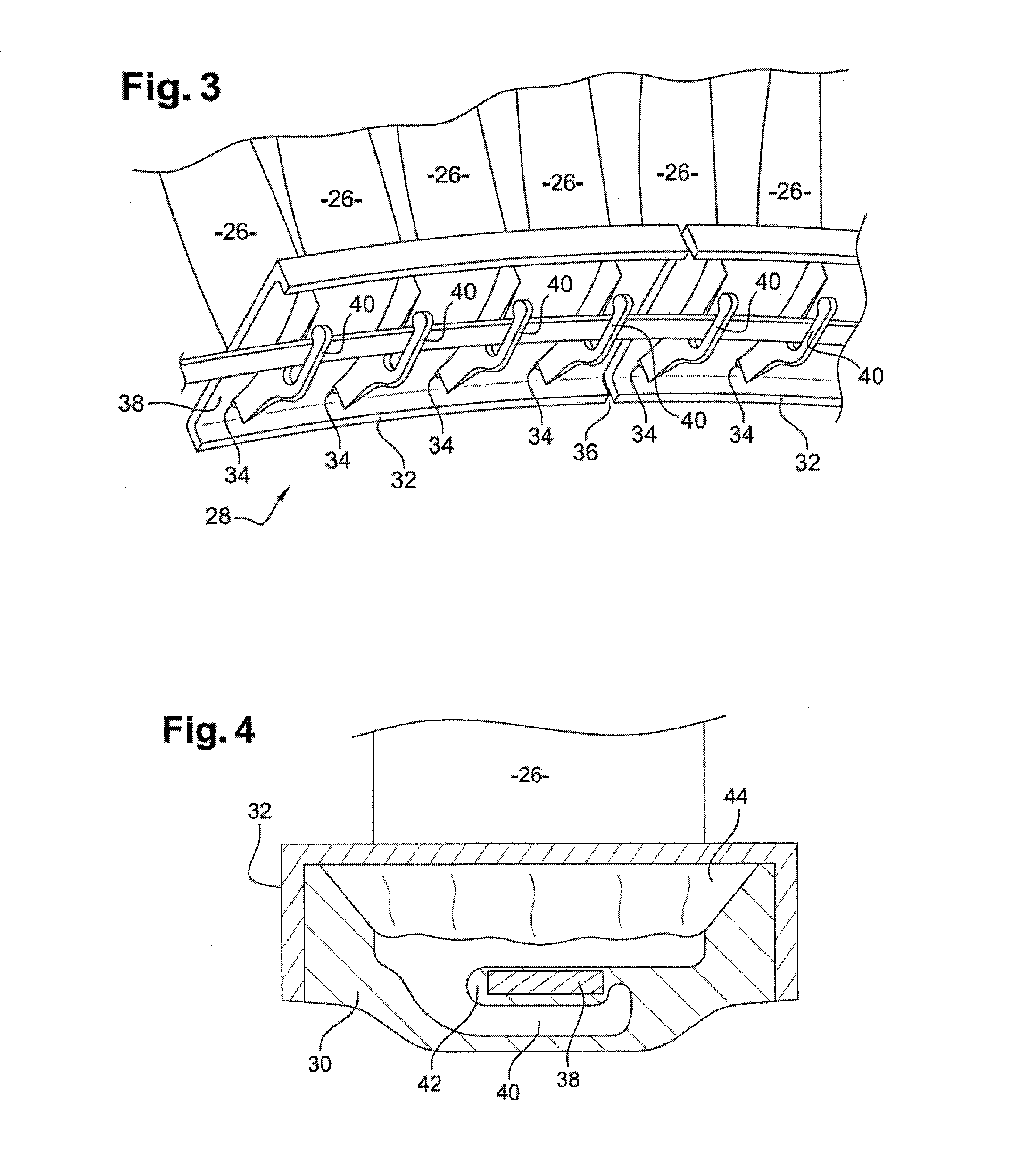

[0015]The present application aims to solve at least one of the problems present in the prior art. More particularly, the present application aims to improve the vibrational behaviour of a stator with a segmented inner shell. The present application also aims to improve the construction of stators, particularly in terms of the connections between the blades and the inner shell.

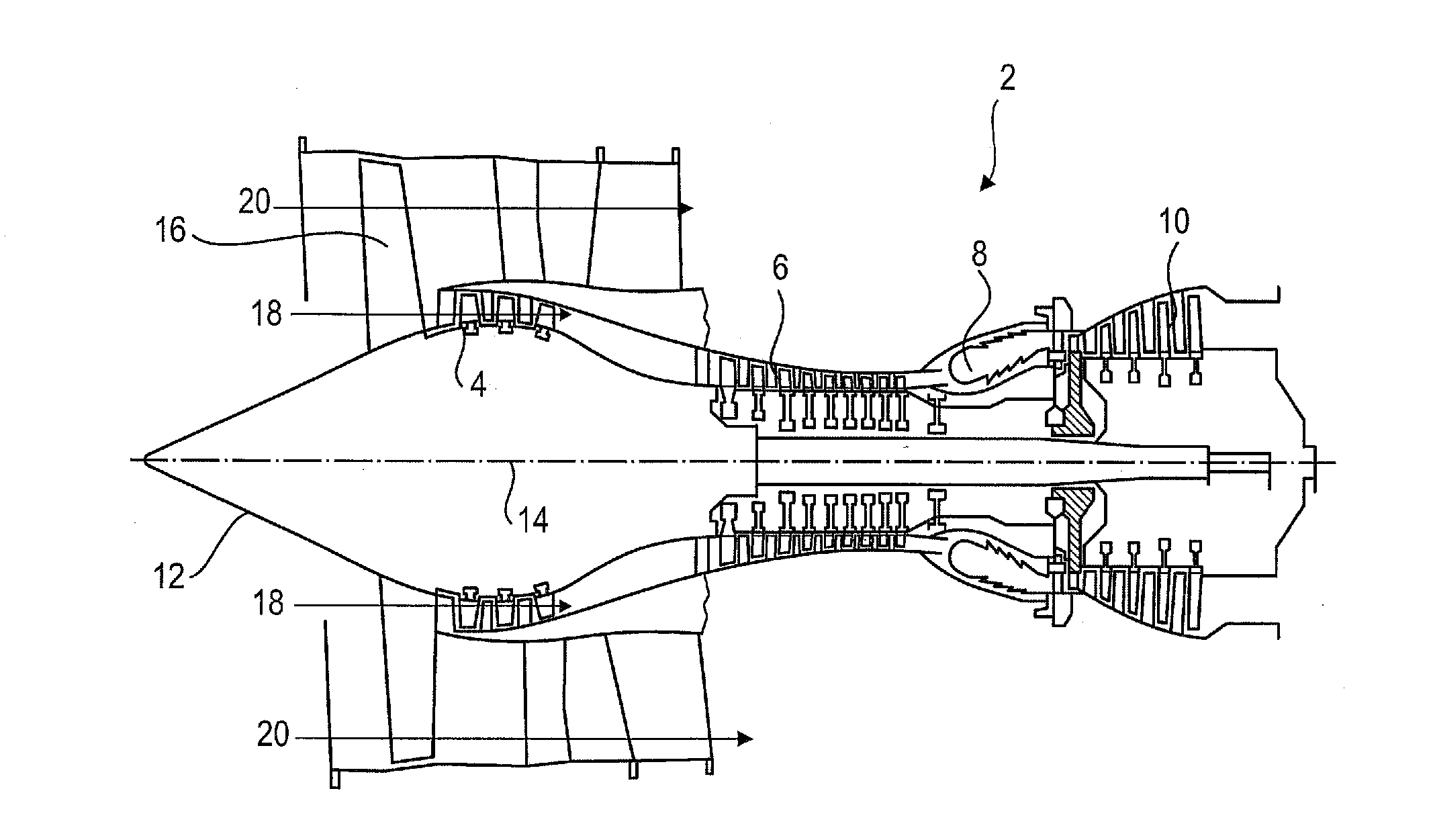

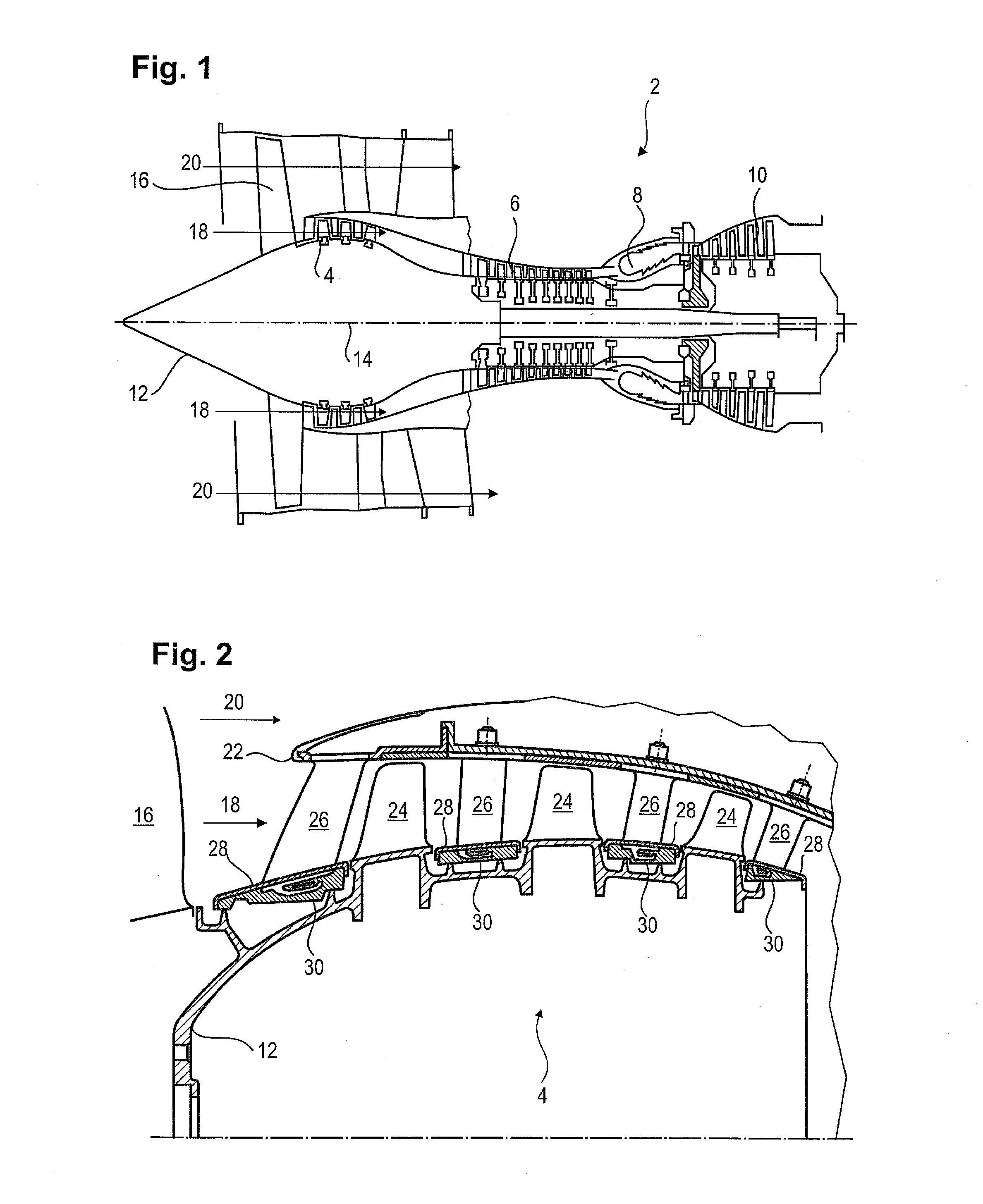

[0016]The present application relates to a stator of an axial turbomachine compressor comprising an annular row of blades extending radially, an inner shell through which the inner tips of the blades pass, the said annular shell being formed of segments arranged end to end, wherein it further comprises at least one strip extending circumferentially along the inner surface of the shell and mating with an engaging member on the inner tips of the blades for their retention, the said strip(s) extending continuously along at least two adjacent annular segments.

[0017]According to an advantageous embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com