Combustor liner for a can-annular gas turbine engine and a method for constructing such a liner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

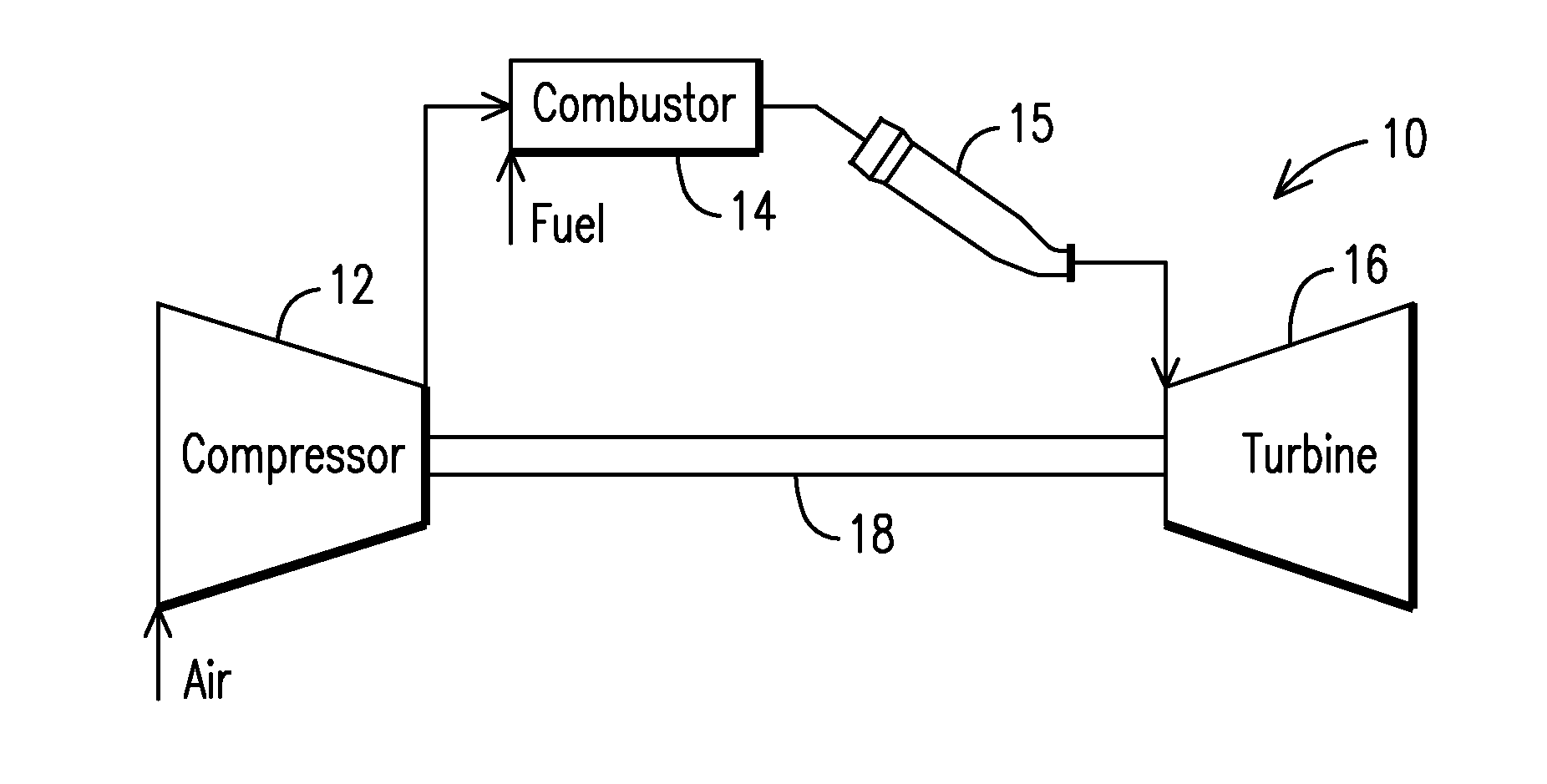

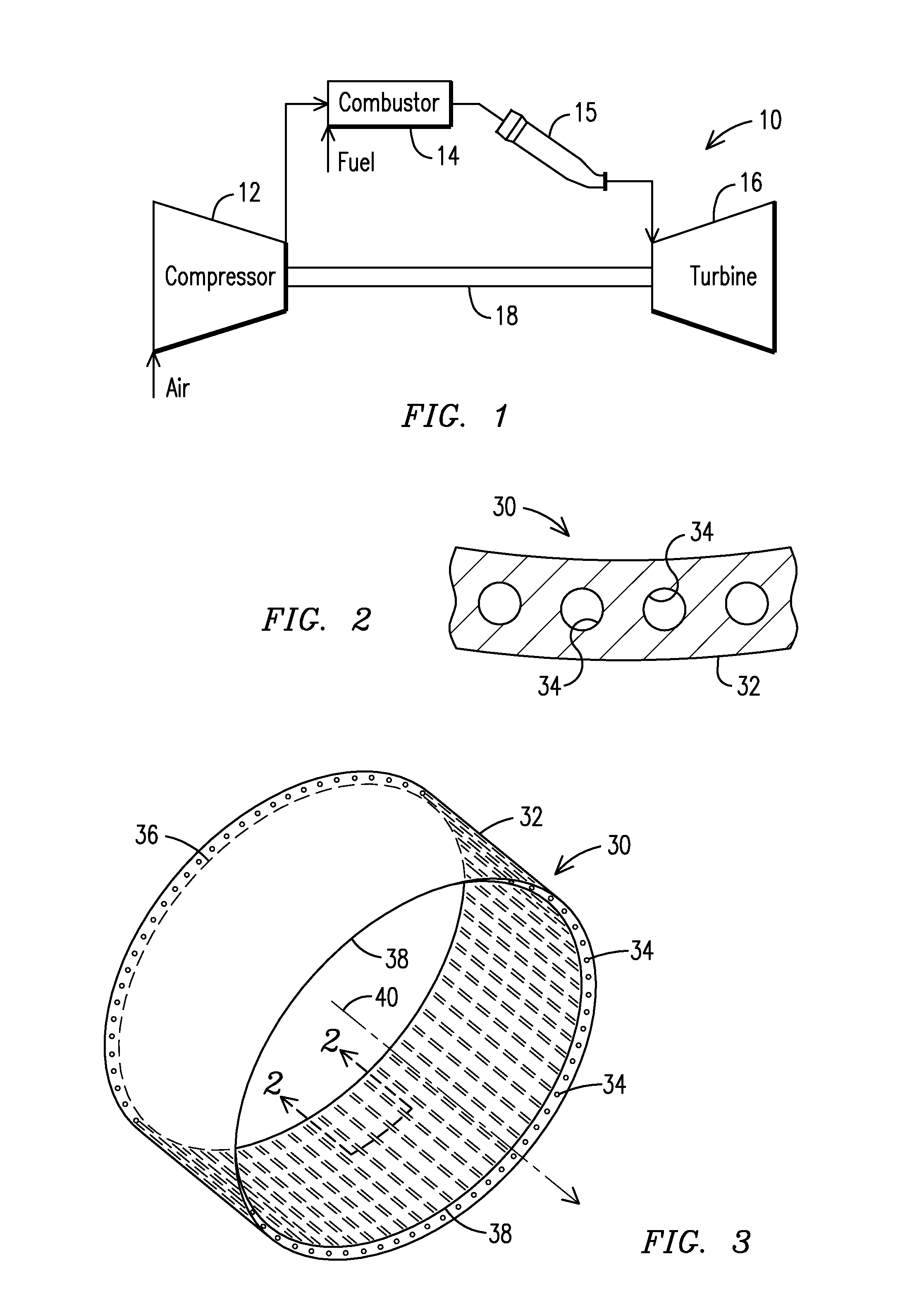

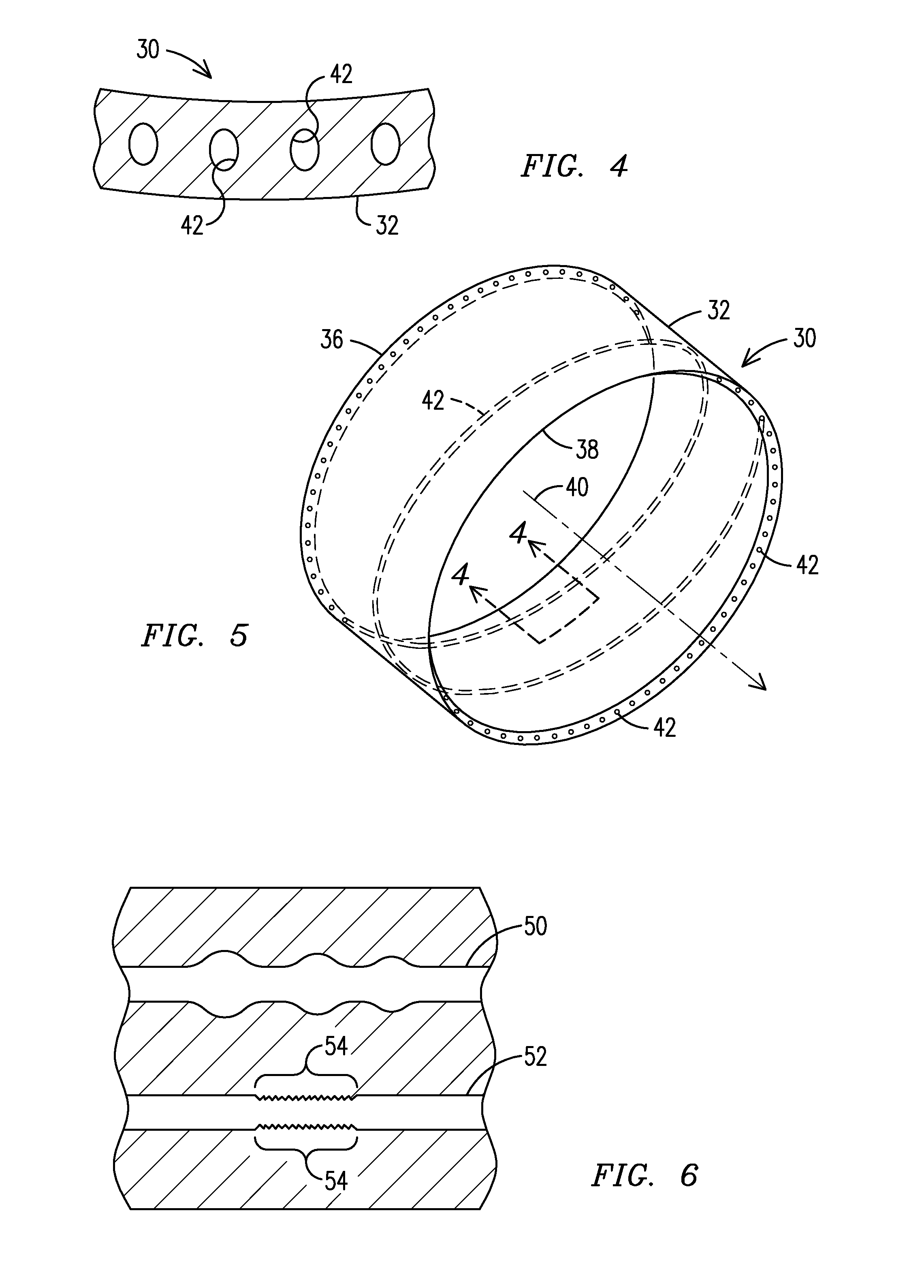

[0014]The present inventors have innovatively recognized certain limitations in connection with known combustor liners for can-annular gas turbine engines. For example, structural limitations of known combustor liners may impede the ability to vary one or more properties of the cooling channel along a length of the cooling channel This ability would allow tailoring the cooling channel to more efficiently meet expected thermal transfer demands along the combustor liner In view of such recognition, the present inventors propose an innovative combustor liner for a can-annular gas turbine engine, and a method for constructing such a liner, where a cooling channel may be formed through the combustor liner using a process for forming a structure, such as may involve complex geometries and / or tightly-controlled tolerances In one non-limiting embodiment, the forming process may be based on subtraction of material, such as an electro-chemical machining (ECM) process In another non-limiting e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com