Seat-belt lock assembly

a belt buckle and assembly technology, applied in the direction of vehicle components, signalling/lighting devices, optical signalling, etc., can solve the problems of insufficiently meeting the requirements of previous belt buckle assemblies, not or only with great effort, and not allowing the subsequent opening and exchange of lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

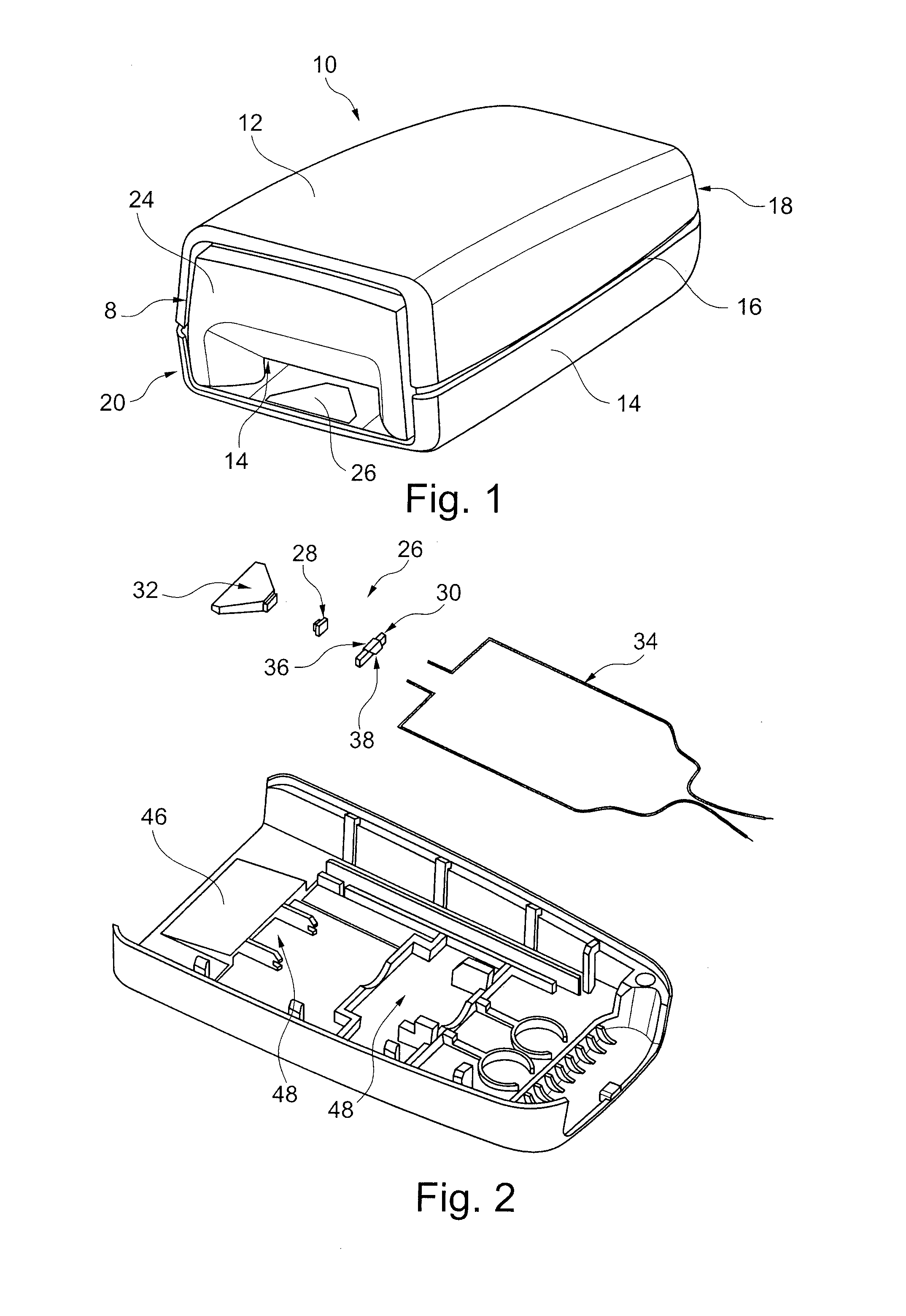

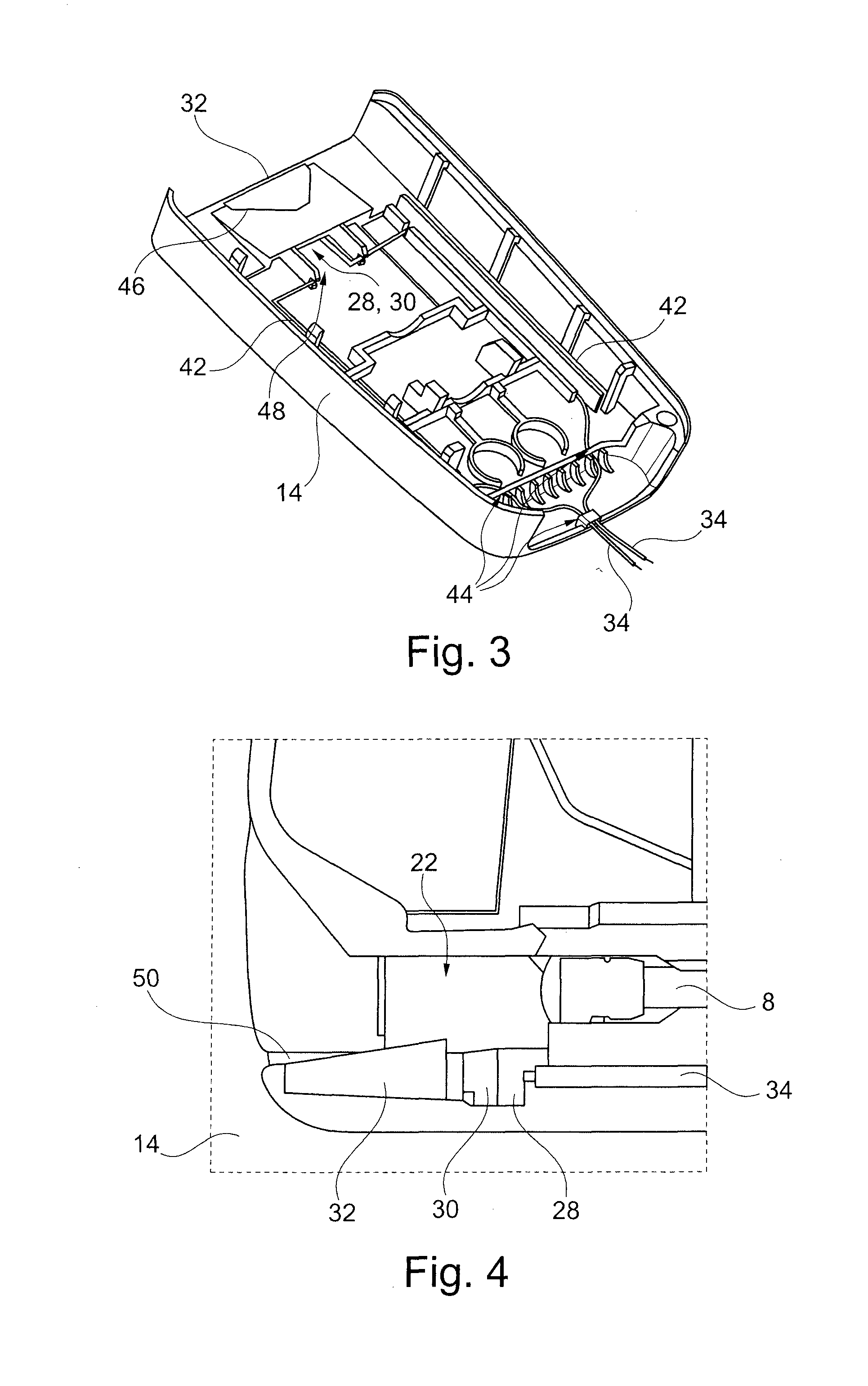

[0018]In FIG. 1 a belt buckle assembly 8 comprising a belt buckle casing 10 is shown having an upper belt buckle shell 12 and a lower belt buckle shell 14. The belt buckle casing 10 substantially corresponds to a conventional belt buckle casing the belt buckle shells 12, 14 are interconnected by adhesive closure along a weld 16, for instance by ultrasonic welding.

[0019]At a rear end 18 the belt buckle casing 10 is fastened on the vehicle side via fittings. At the opposite front end 20 an insertion aperture 22 for a plug-in tongue not represented here as well as an operating key 24 for releasing the plug-in tongue are shown.

[0020]Moreover, a lighting device 26 the structure of which will be explained hereinafter is provided at the insertion aperture 22.

[0021]The lighting device 26 substantially consists, as is evident from FIG. 2, of a lamp 28, in this case an LED, a carrier member 30 for the lamp 28, a light conductor 32 as well as two cables 34 for establishing a contact between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com