Materials handling and treatment

a technology of material handling and treatment, applied in the direction of filtration separation, moving filter element filter, separation process, etc., can solve the problems of difficult ensuring, messy process, uneven sludge spread across the bel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

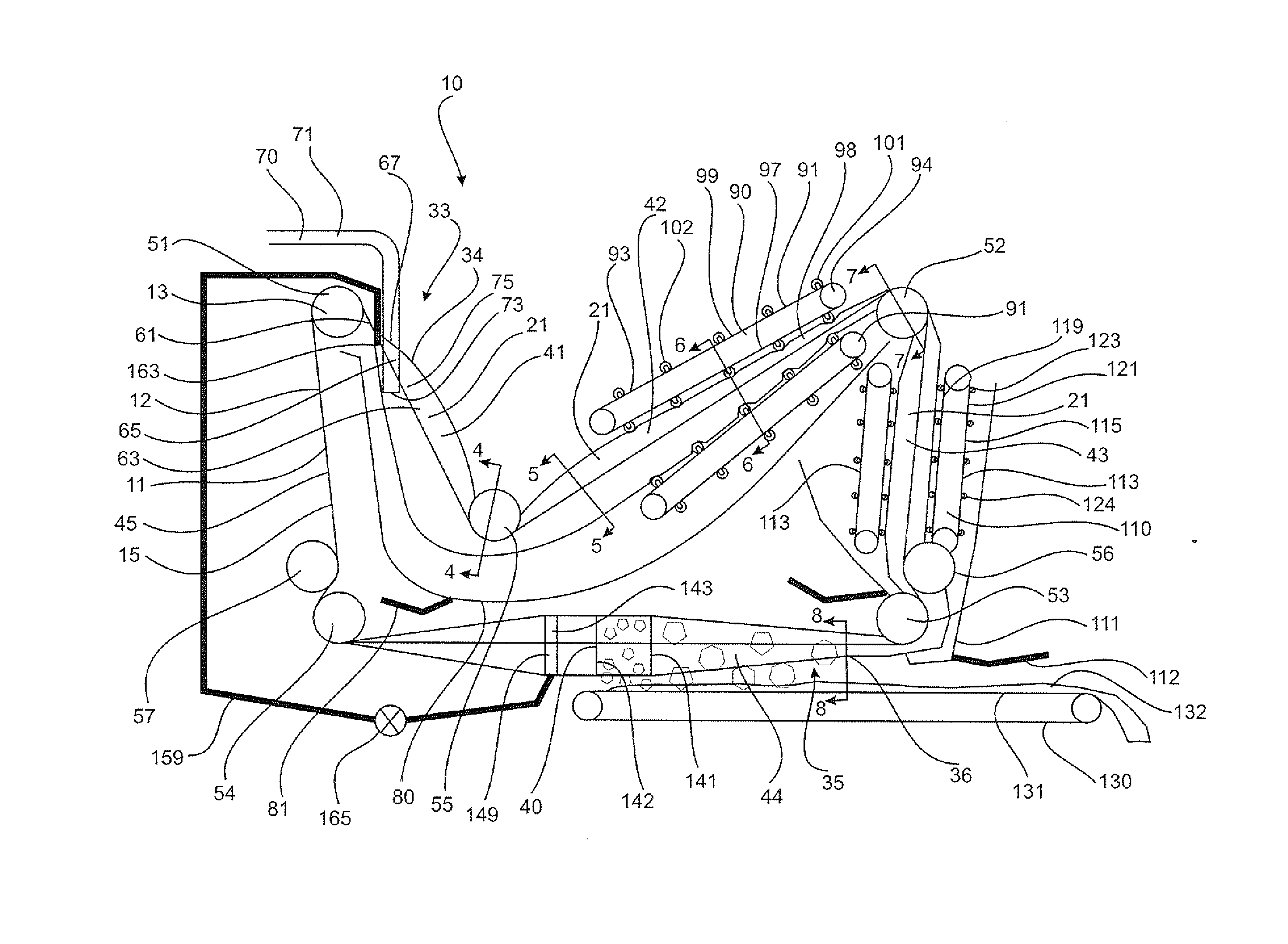

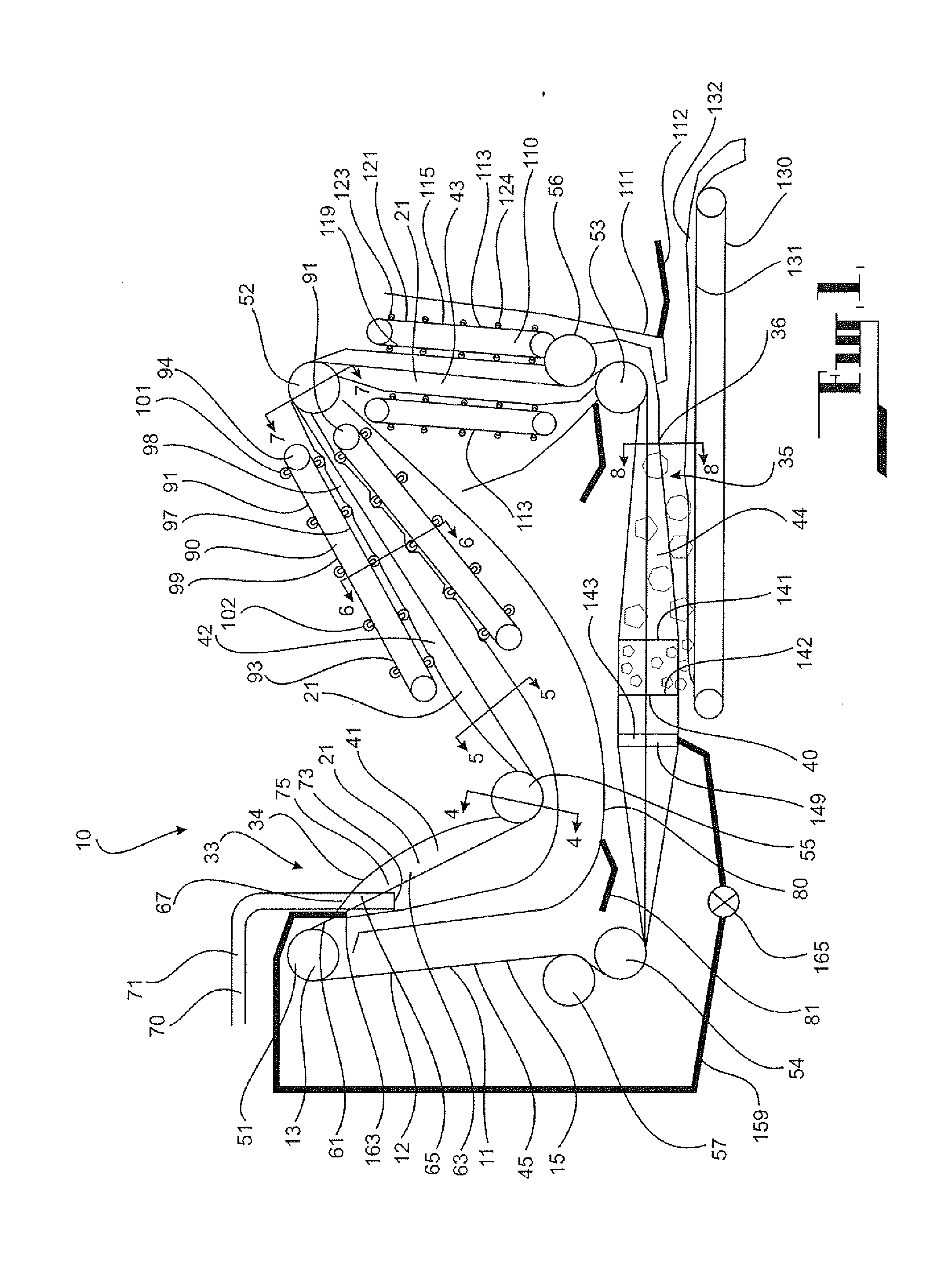

[0081]The first embodiment, which is shown in FIGS. 1 to 11 of the drawings, is directed to a belt filter apparatus 10 for treating material to separate solid and liquid components thereof. The apparatus 10 according to this embodiment has been devised particularly for treating sludge material such as sewage for the purposes of dewatering the sludge material to facilitate recovery of the solid matter for subsequent treatment. There may, of course, be various other applications for the belt filter apparatus 10.

[0082]The apparatus 10 comprises an endless belt structure 11 adapted to circulate around a path 12 incorporating guide roller structures 13 around which the belt structure passes.

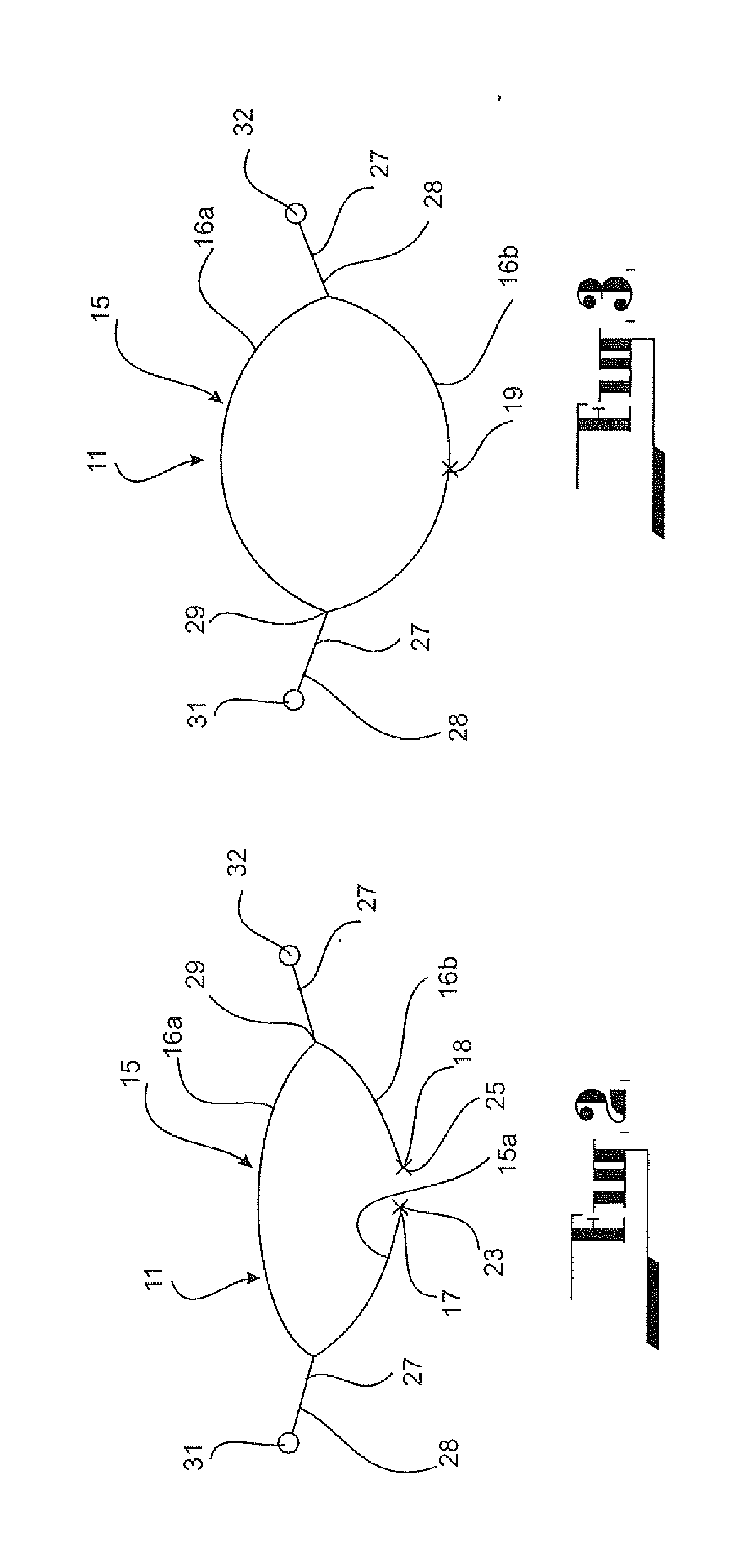

[0083]The endless belt structure 11 comprises an elongate belt portion 15 formed of sheet material; specifically, water permeable sheet material, such as for example a flexible filter pad material such as woven polypropylene. The belt portion 15 comprises two opposed longitudinal edges 17, 18. The bel...

second embodiment

[0130]Referring now to FIGS. 12 and 13, there is shown a belt filter apparatus 200 according to a This embodiment is similar in some respects to the previous embodiment and similar reference numerals are used to denote corresponding parts.

[0131]In this embodiment, the tubular structure 21 turns about two turn rollers 201 in moving between the first run 41 and the second run 42. The two rollers 201 are spaced apart and a section 203 of the tubular portion 21 draped therebetween.

[0132]The belt filter apparatus 200 includes two pressing stations 90, 110 as was the case with the previous embodiment. However, in this embodiment, the second pressing station 110 is arranged along a horizontal run 205 of the belt structure 11 rather than a vertical run. Further, at the pressing station 110, the cams 123 on opposed sides of the tubular structure 21 locate between each other to subject the tubular structure 21 to a peristaltic pressing action, as best seen in FIG. 13. The pressing station 11...

fourth embodiment

[0140]Referring now to FIGS. 16 to 21, there is shown a belt filter apparatus 300 for treating material to separate solid and liquid phases thereof. The apparatus 300 has been devised particularly for treating sewage for the purposes of dewatering the sewage to facilitate recovery of the solid matter for subsequent treatment. There may, of course, be various other applications for the belt filter apparatus.

[0141]The apparatus 300 comprises an endless belt structure 311 passing around guide rollers 313.

[0142]The endless belt structure 311 comprises an elongate belt portion 315 formed of water permeable material such as for example a flexible filter pad material. The belt portion 315 has two opposed longitudinal edges 317, 318. The endless belt 311 further comprises a connection means 319 for releasably connecting the two longitudinal edges 317, 318 together so as to form a tubular structure 321 having a flexible side wall 322. The connection means 319 comprises a slider connector me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| axial tension | aaaaa | aaaaa |

| gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com