Turbine blade and associated method for producing a turbine blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

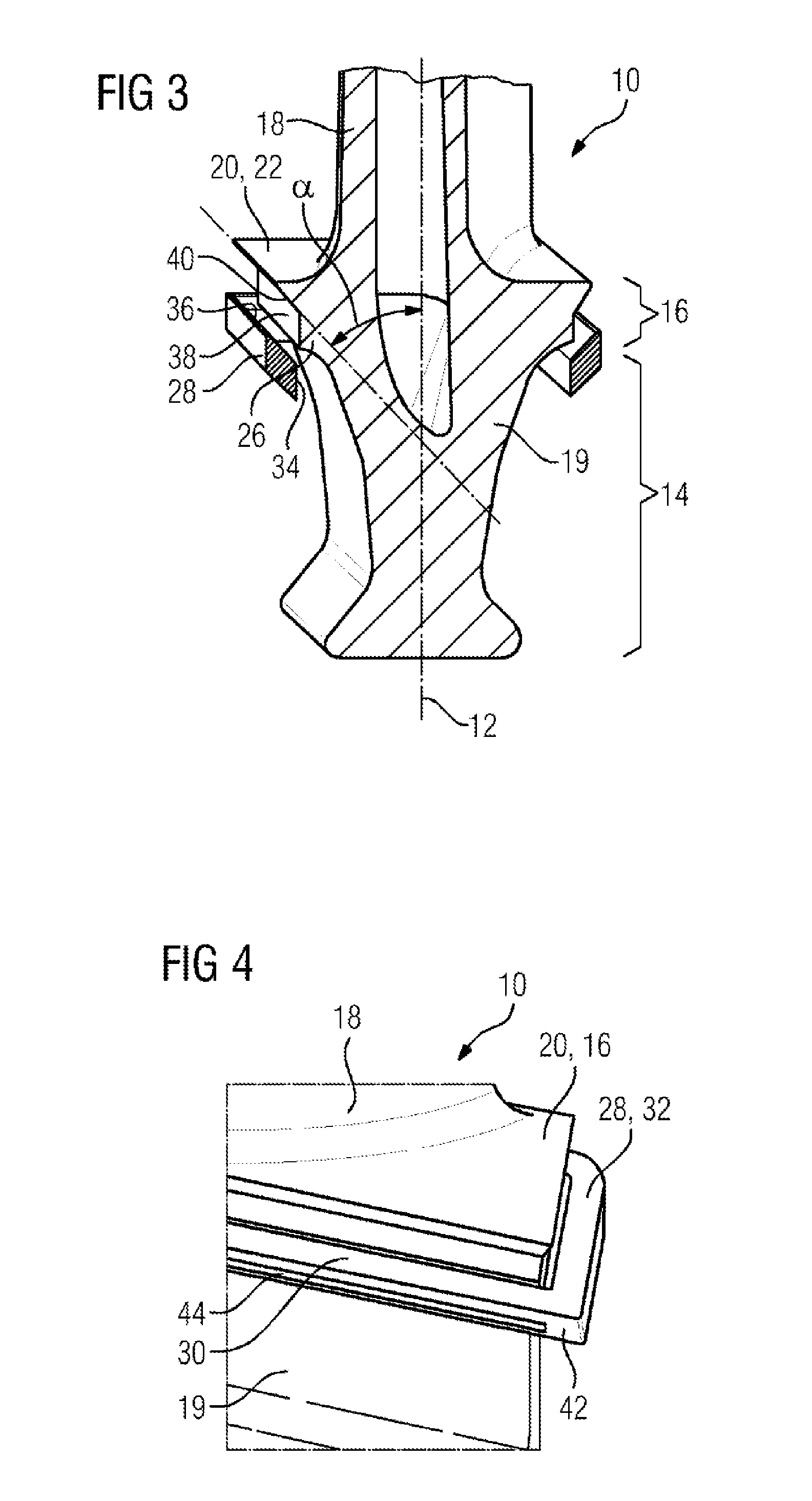

[0032]Identical features are given identical reference numerals in all the figures.

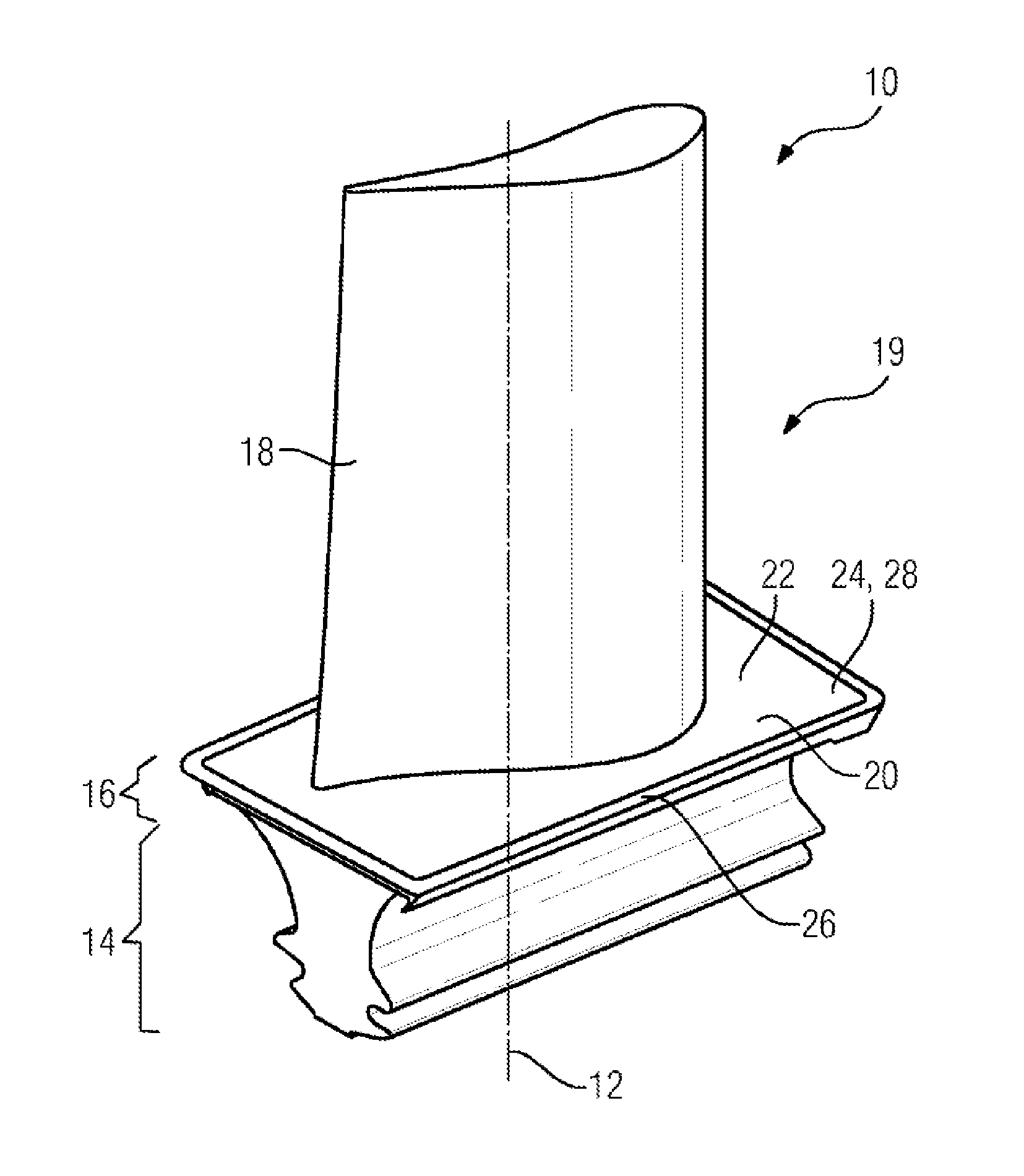

[0033]FIG. 1 shows a perspective illustration of a turbine blade 10. The turbine blade 10 is designed as a moving blade. However, it may also be designed as a guide blade. The turbine blade 10 comprises, succeeding one another directly along its longitudinal axis 12, a fastening portion 14, a platform 16 and a blade airfoil 18. The fastening portion 14 is contoured in a manner of a pine tree profile in a way typical of a moving blade. Guide blades for turbines mostly have, instead of the pine tree-shaped fastening portion 14, a plurality of hooks which are pushed into a guide blade carrier, not illustrated in any more detail, of the turbomachine.

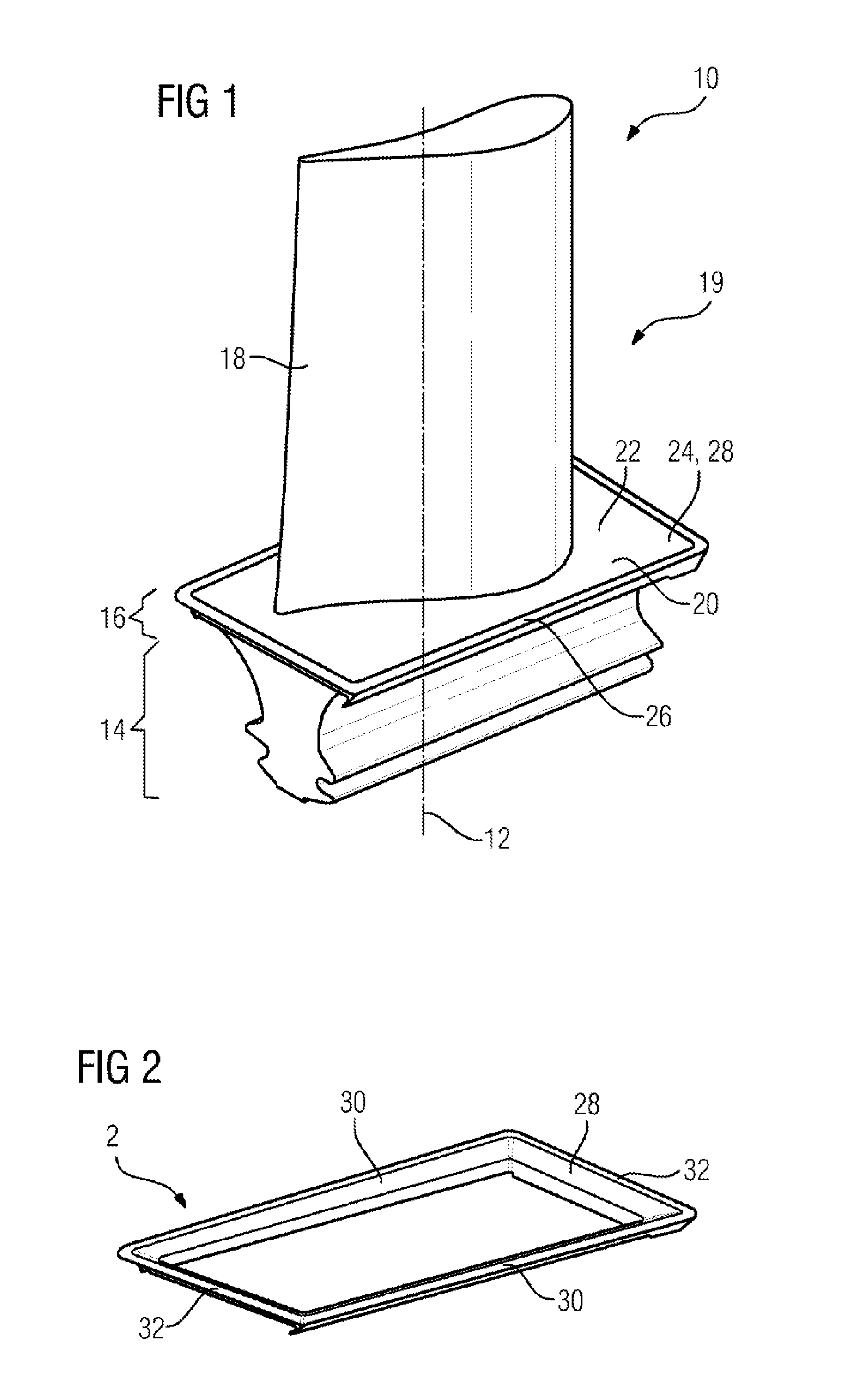

[0034]The fastening portion 14 merges into the platform 16. According to the illustration chosen in FIG. 1, the platform 16 has an upwardly pointing platform surface 20 on which the blade airfoil 18 is seated. In the exemplary embodiment illustrated, the platf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com