Heat transfer engine

a heat transfer engine and heat transfer technology, applied in the direction of steam engine plants, machines/engines, lighting and heating apparatus, etc., can solve the problems of limited heat load and distance, general limitation of passive methods, etc., and achieve the effect of reducing the overhead of external power and yielding flexibility in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

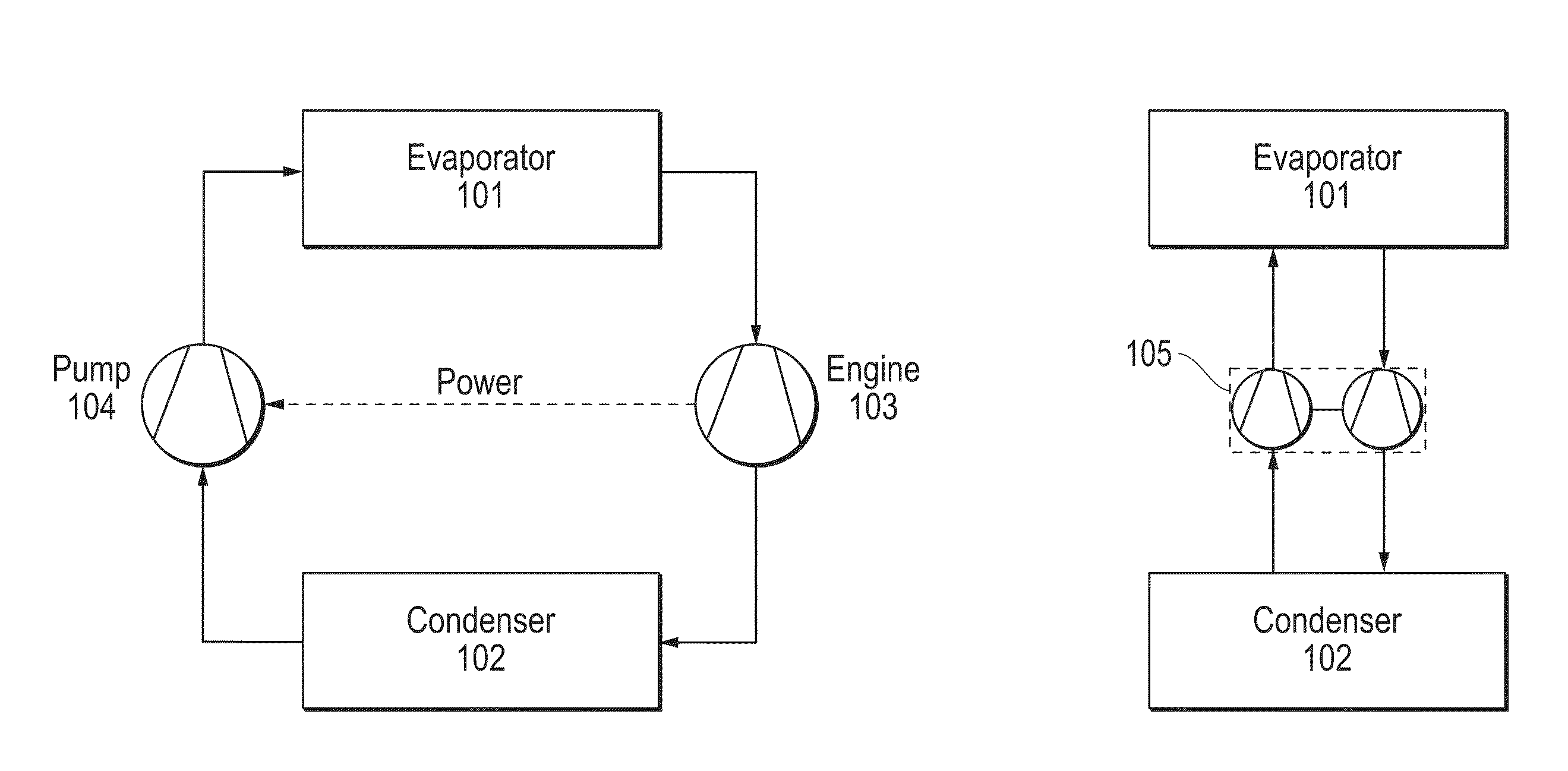

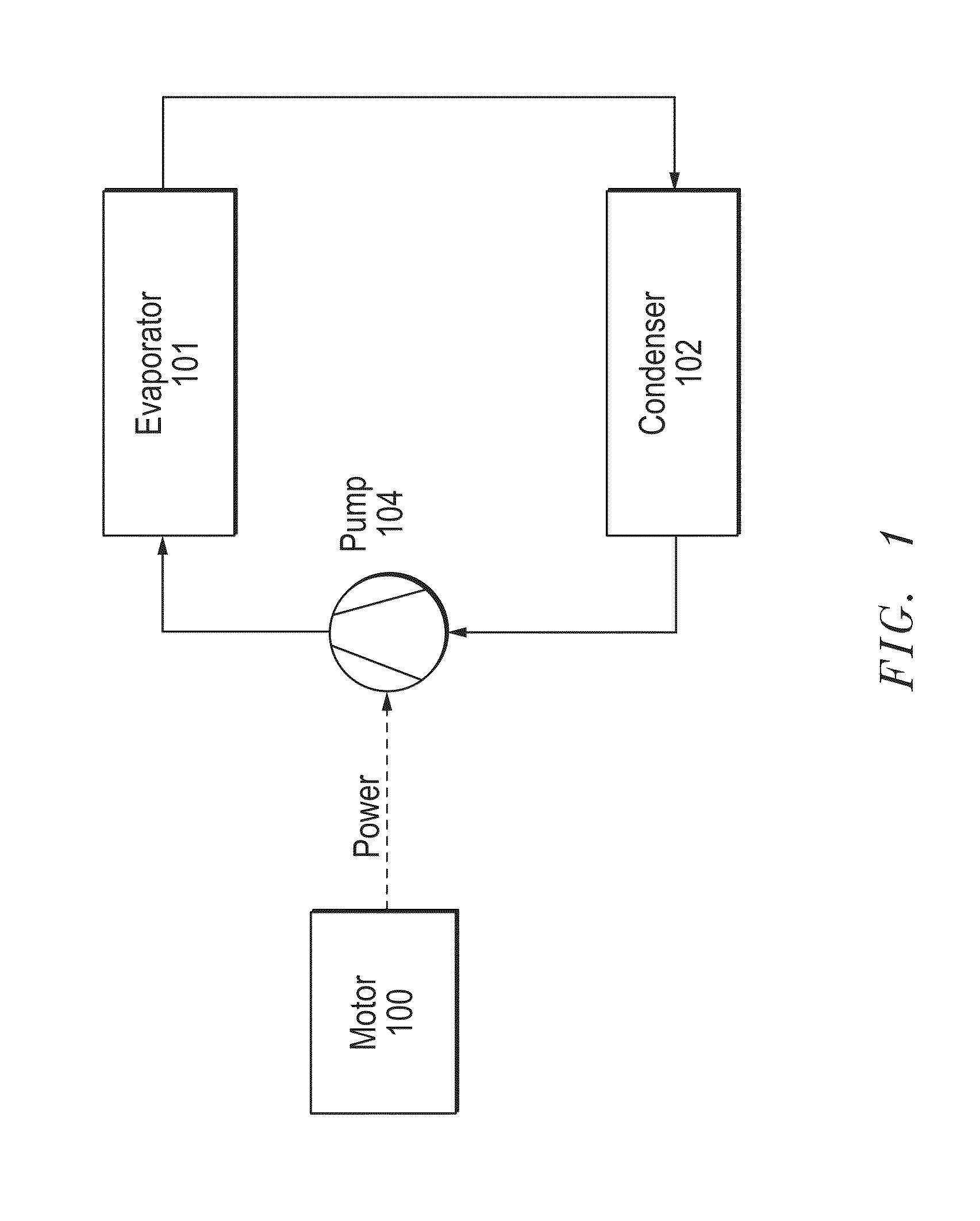

[0022]A typical pumped two-phase closed loop heat transfer system is presented in FIG. 1. This system consists of a motor 100, a pump 104, an evaporator 101, and a condenser 102. The pump 104 which is driven by the motor 100, receives it's liquid from the condenser 102, and delivers the liquid to the evaporator 101. There are three energy exchanges into or out of this system. Electrical energy is input into the motor 100, which is converted into mechanical energy. Thermal energy is input into the evaporator 101, which vaporizes the liquid. Thermal energy is removed from the condenser 102, which condenses the vapor back to liquid.

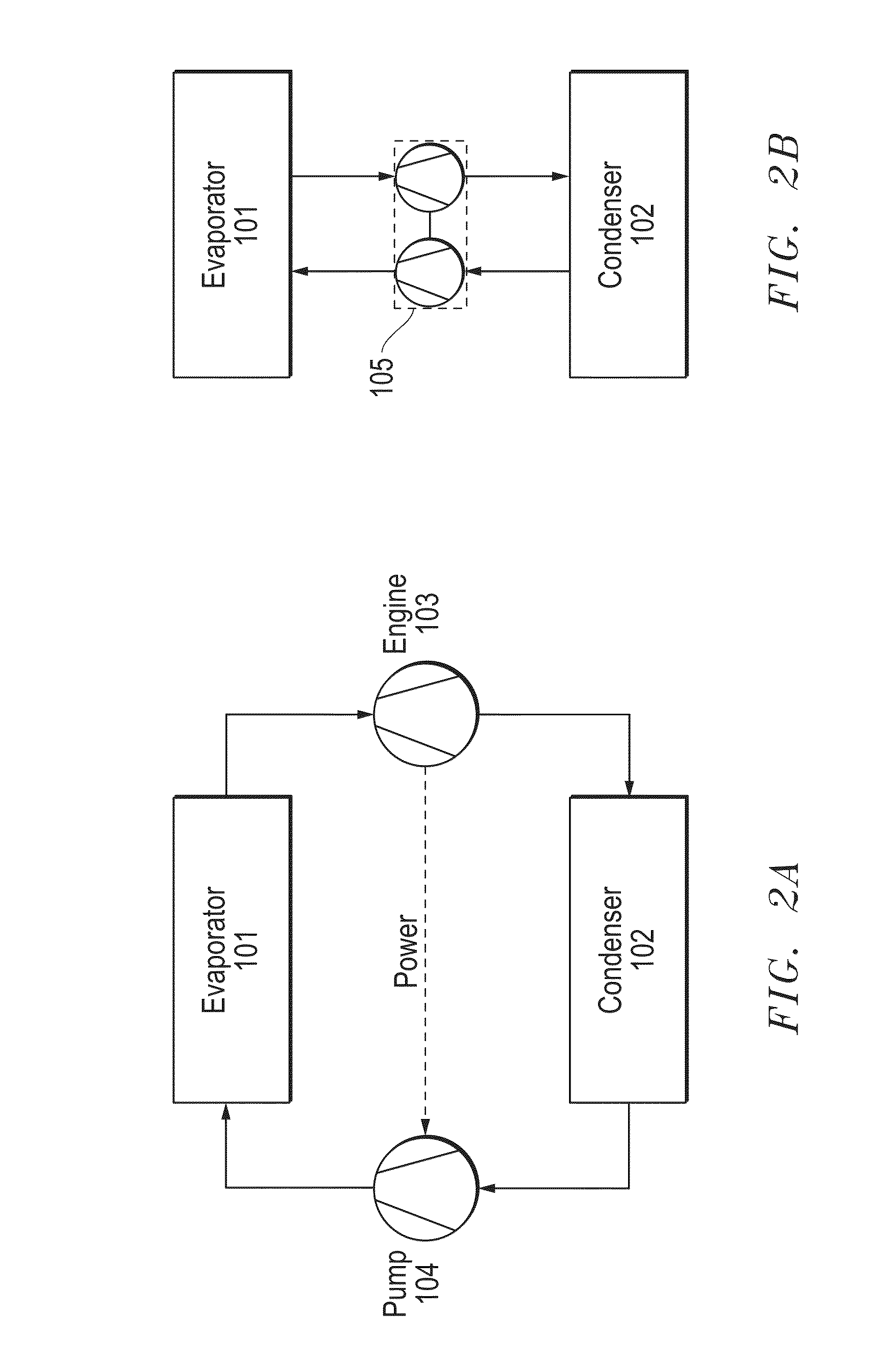

[0023]One embodiment of the present invention is represented in a basic schematic in FIG. 2A, and includes an evaporator 101, a condenser 102, an engine 103 and a pump 104. The engine and pump are both positive displacement devices, and all power generated by the engine 103 drives the pump 104. While the engine 103 is a positive displacement type, it should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com