Shackle assembly with locking pin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

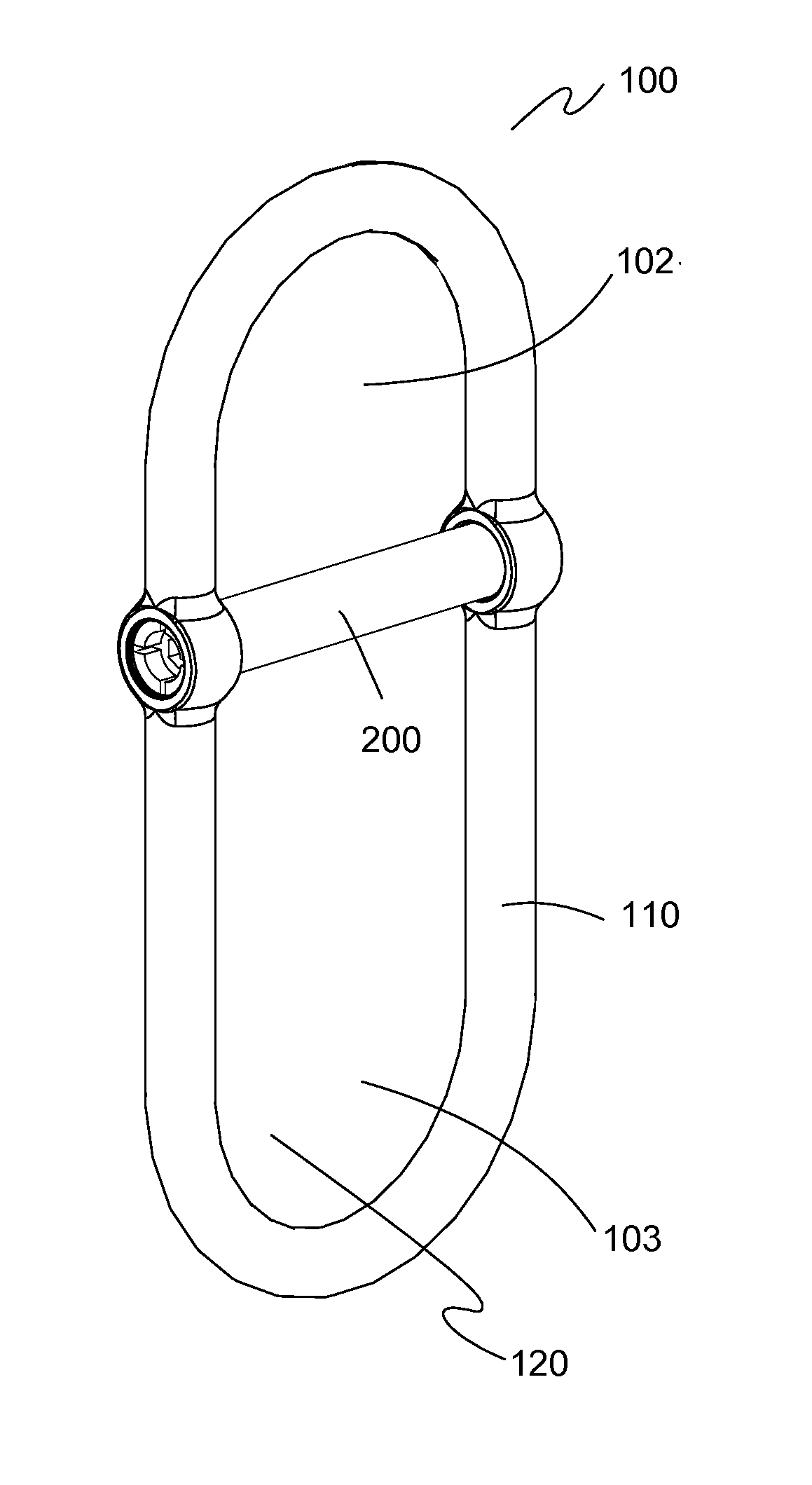

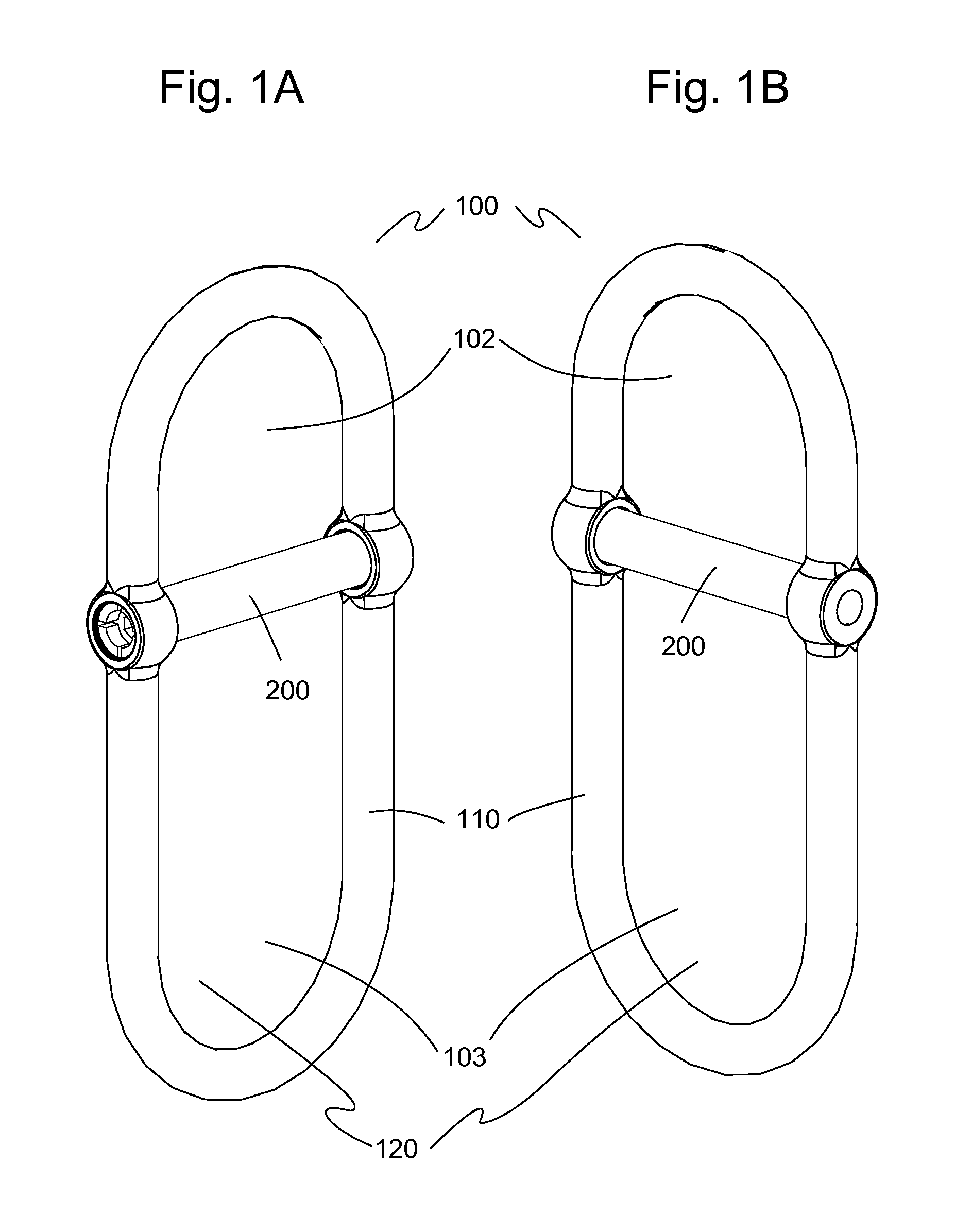

[0078]The preferred embodiments of a shackle assembly 100 of the present invention are illustrated in FIGS. 1-20. FIGS. 1A and 1B illustrate front and rear perspective views, respectively, of one embodiment of a shackle assembly 100 having a body 110 and a pin 200. Body 100 in this embodiment defines a closed oval shape. Pin 110 passes transversely through body 110, dividing a primary opening 120 into two smaller openings 102, 103.

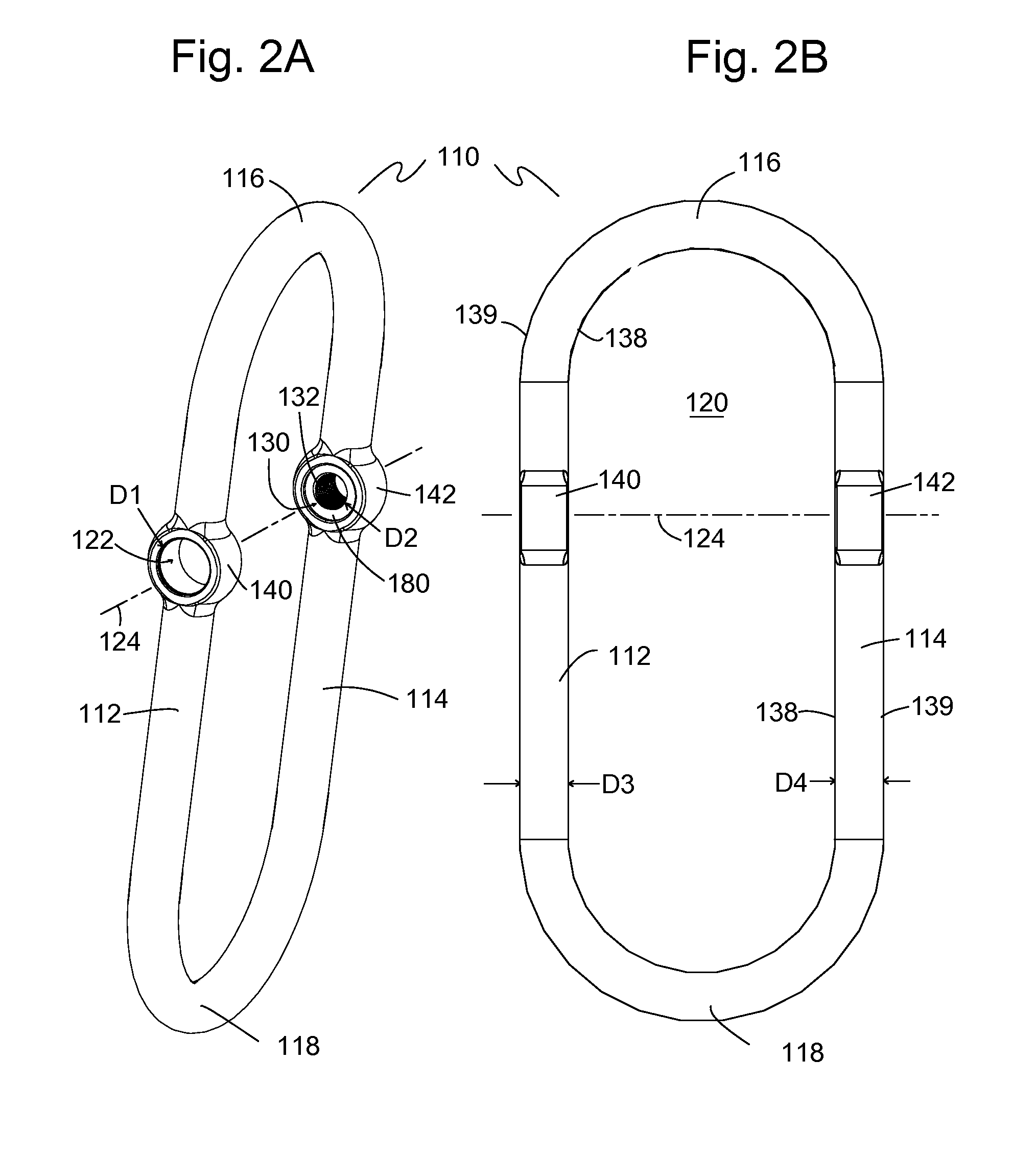

[0079]Referring now to FIGS. 2A and 2B, perspective and front views, respectively, illustrate the embodiment of body 110 as shown in FIG. 1. In one embodiment, body 110 has a longitudinal first side portion 112, a longitudinal second side portion 114 spaced apart from and extending substantially parallel to first side portion 112, a first end portion 116, and a second end portion 118 opposite first end portion 116. Body 110 has an inside body surface 138 and an outside body surface 139. First and second end portions 116, 118 each connect between longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com