Heat radiation sheet and method of manufacturing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

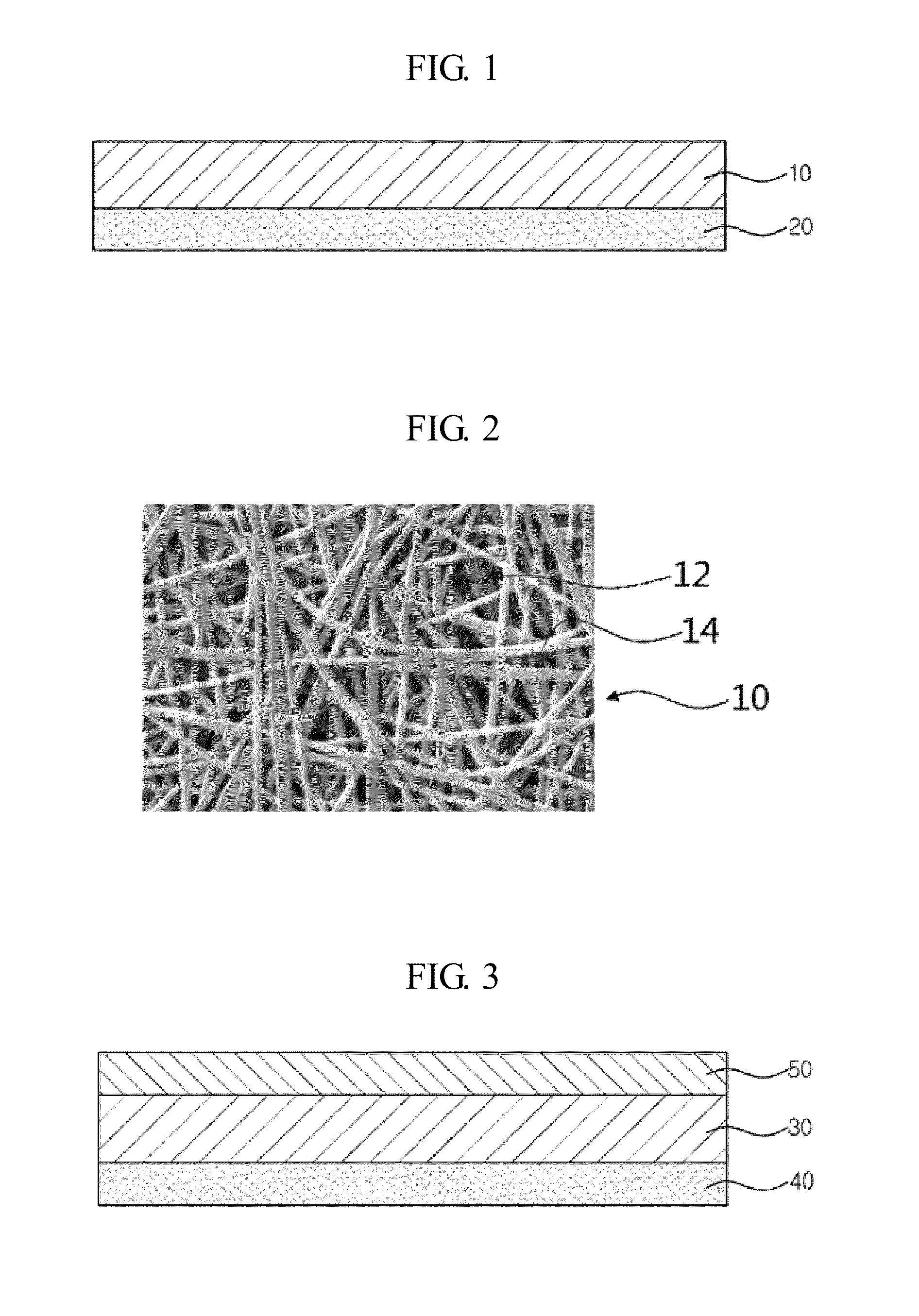

[0022]Referring to FIGS. 1 and 2, the heat radiation sheet includes: a heat radiation layer 10 that is formed in a nano-web by an electrospinning method in which a heat conductive material is contained in the heat radiation layer 10, to thus have thermal conductivity; and an adhesive layer 20 that is laminated on one surface or both surfaces of the heat radiation layer 10.

[0023]The heat radiation layer 10 is formed by the following steps of: mixing a polymer material that can be electrospun and a solvent, or the polymer material, a heat conductive material, and the solvent at a constant mixture rate, to thus produce a spinning solution; electrospinning the spinning solution to thus form nanofibers 14; and accumulating the nanofibers 14 to thus form a nano-web having a plurality of pores 12. Here, the term “nano-web” can be called the ‘web’ shortly.

[0024]Here, the spinning method that is applied to the present invention can employ any one selected from general electrospinning, air-e...

second embodiment

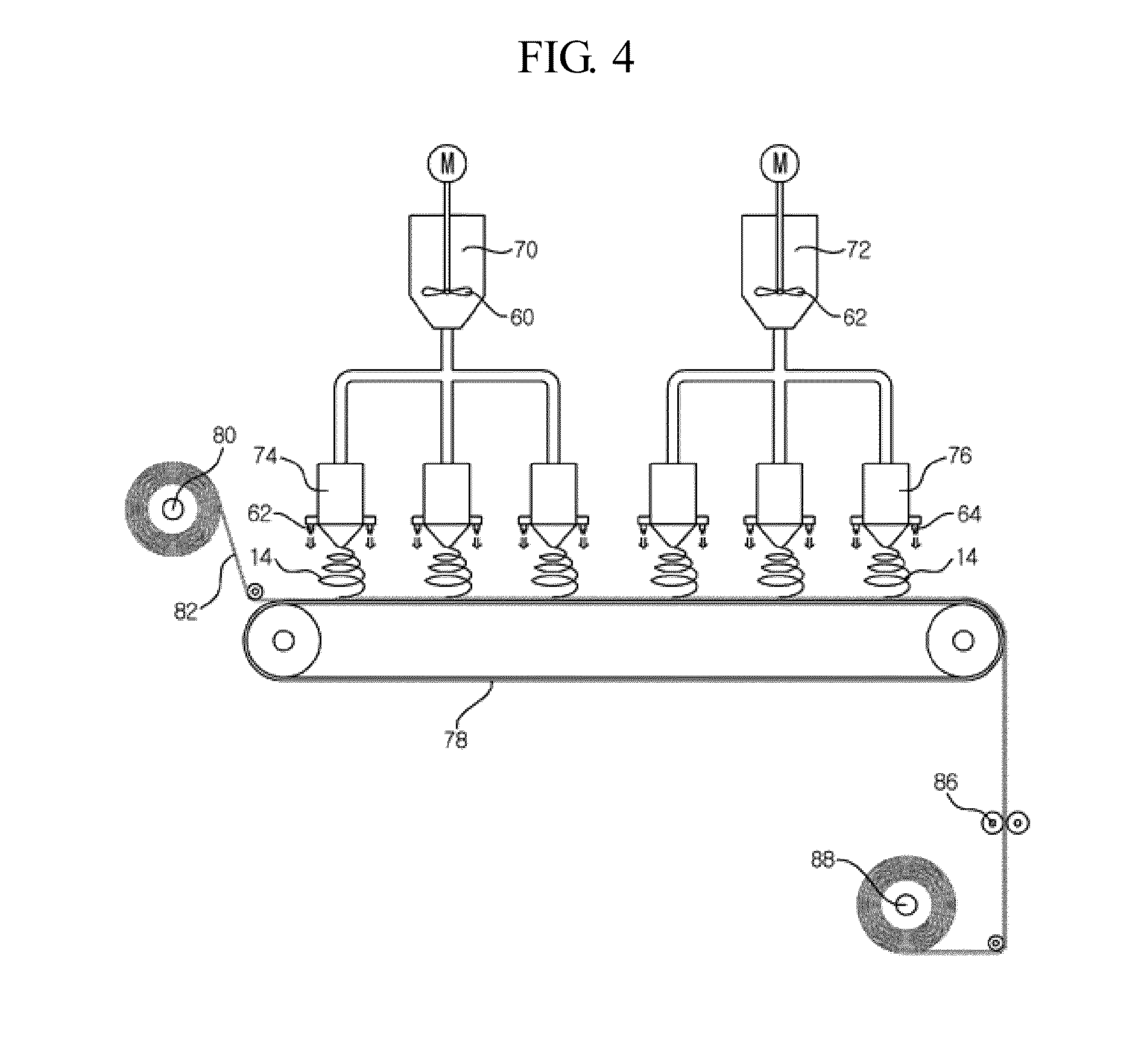

[0041]FIG. 3 is a cross-sectional view of a heat radiation sheet according to the present invention.

[0042]Referring to FIG. 3, the heat radiation sheet according to the second embodiment includes a substrate 30 that is formed in a nano-web shape by the electrospinning method, an adhesive layer 40 that is laminated on one surface of the substrate 30, and a metal layer 50 that is coated on the other surface of the substrate 30 and having thermal conductivity.

[0043]The substrate 30 is formed by the following steps of: mixing a polymer material and a solvent at a constant rate to thus produce a spinning solution having a viscosity so as to be electrospun; electrospinning the spinning solution to thus form nanofibers; and accumulating the nanofibers to thereby form the substrate 30 having a number of pores in a nano-web form.

[0044]Further, the substrate 30 may be formed in the same structure as the heat radiation layer 10 according to the first embodiment. That is, the substrate 30 may b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductor | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com