Vessel with rotatable pod

a technology of displacement vessel and rotatable pod, which is applied in the direction of waterborne vessels, vessel construction, and propulsive elements, etc., can solve the problems of complicated movements and other problems, and achieve the effect of large draught and effective and efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

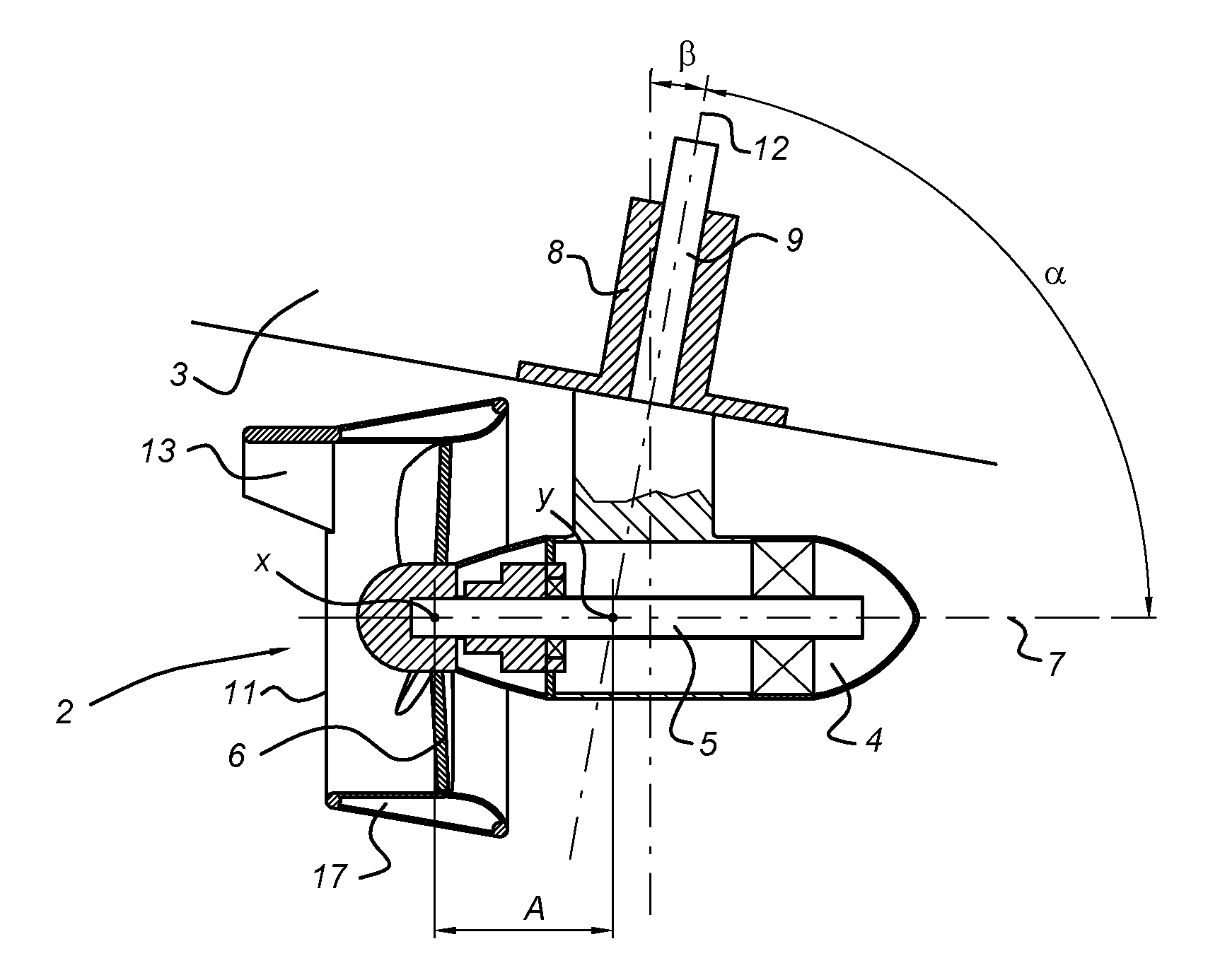

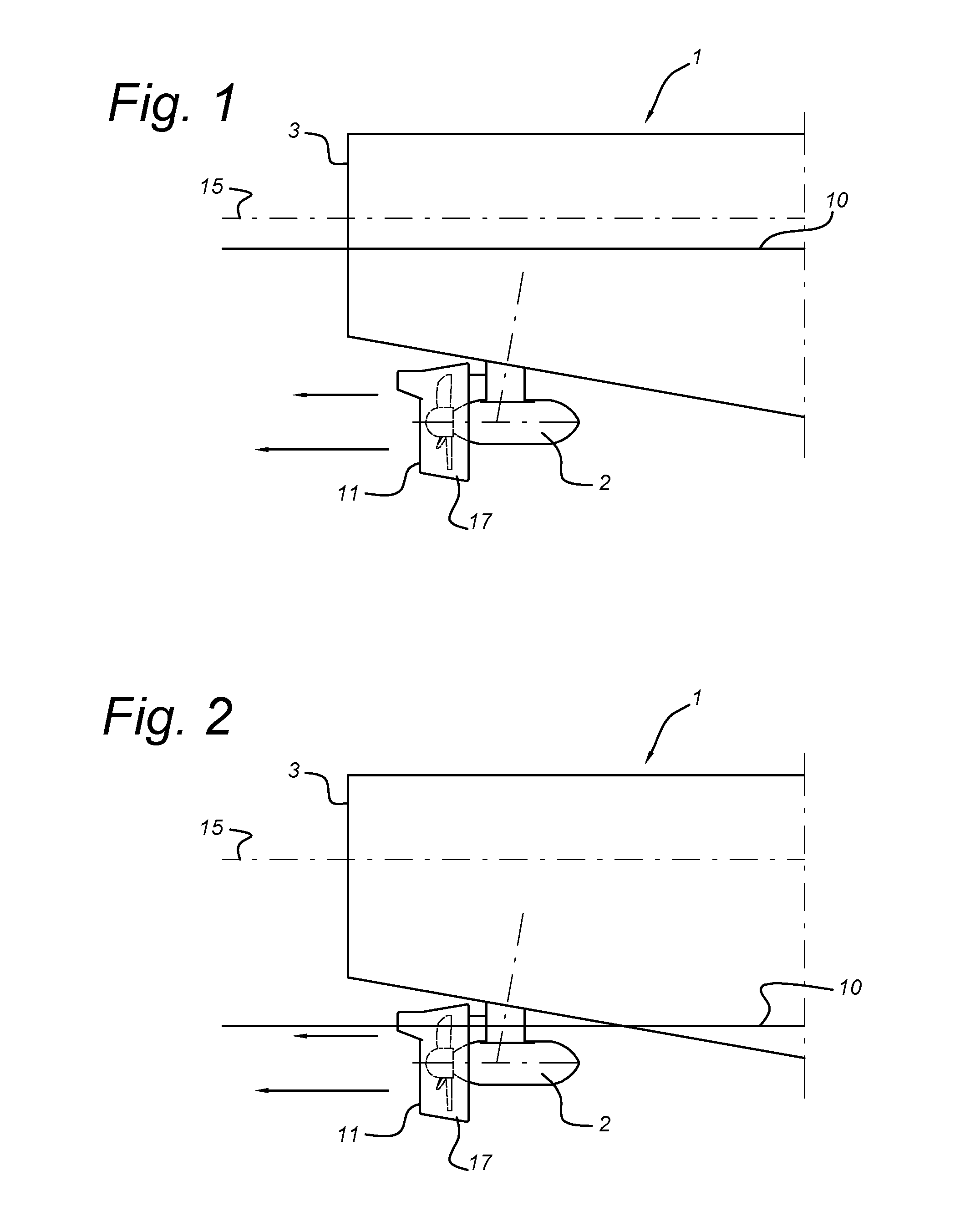

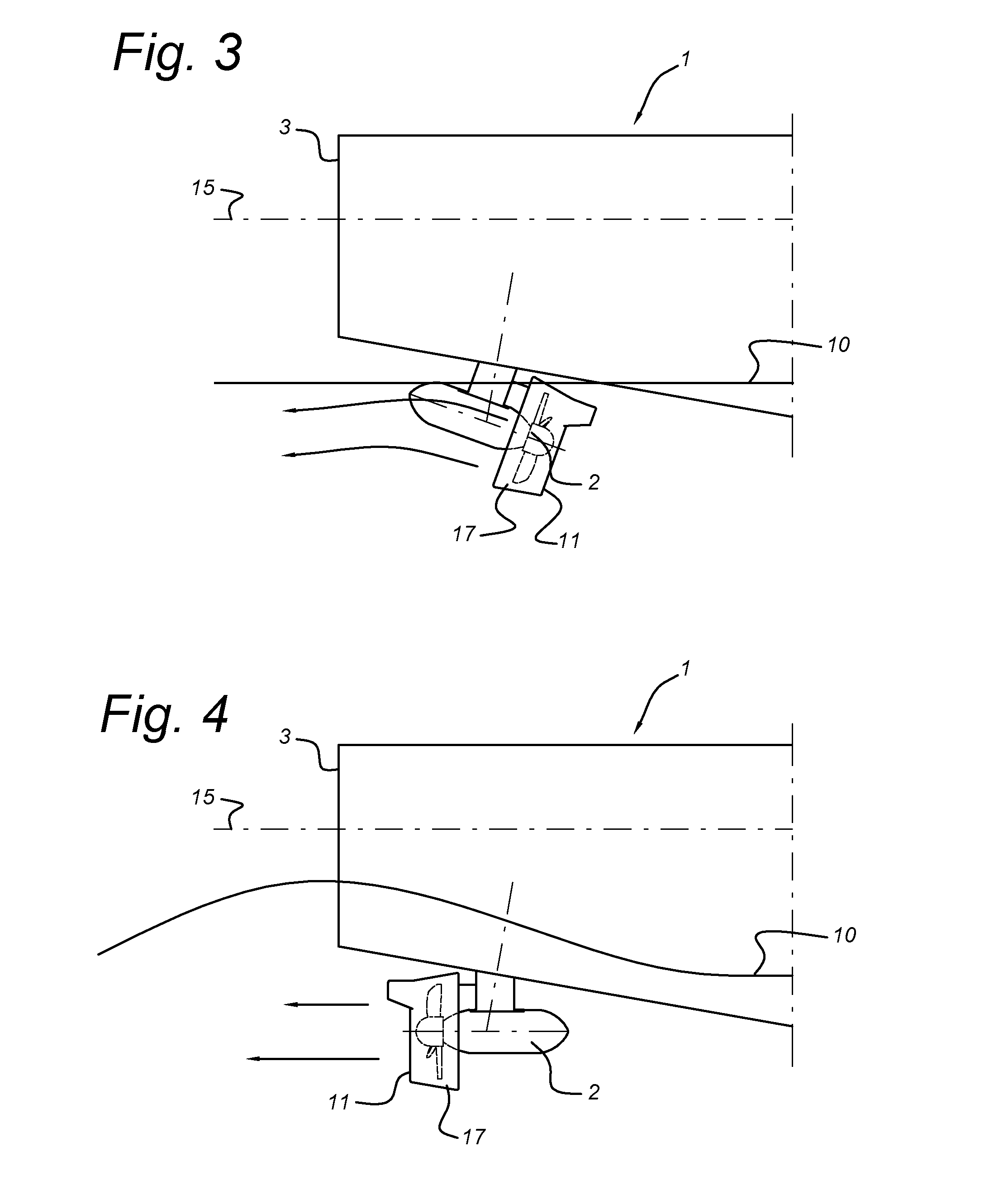

[0042]In FIG. 1, a vessel is designated overall by 1. According to the present invention, this is a relatively large vessel, such as an inland vessel, coaster or larger vessel. The length of the vessel is preferably greater than 20 or 40 metres. The driving power used for such vessels may, for example, be in the range of many kilowatts to several megawatts. The vessel is designated overall by 1 and is provided with a pod 2 at the rear side which is designated by 3. The pod 2 comprises a jet pipe 17 with an inlet delimited by a peripheral edge 11. The waterline in FIG. 1 is indicated by 10 and the longitudinal axis of the hull is indicated by 15. FIG. 1 illustrates the loaded state in which the propeller is entirely under the waterline.

[0043]FIG. 2 illustrates the same vessel 1 in an unladen state, in which the pod is attached in the manner customary in the prior art. It can be seen that the pod, and in particular its propeller, and the inlet of the jet pipe 17 are above the waterlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com