Dental device comprising surgical template and false teeth set and related methods

a dental device and template technology, applied in the field of dental surgery, can solve the problems of imperfect bores, temporary or permanent paresthesia, difficult and accurate placement of implants within the jawbone, etc., and achieve the effect of shortening the surgery time for implantation and greater precision in placemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088]Reference will now be made in detail to various exemplary embodiments of the invention. It is to be understood that the following discussion of exemplary embodiments is not intended as a limitation on the invention. Rather, the following discussion is provided to give the reader a more detailed understanding of certain aspects and features of the invention.

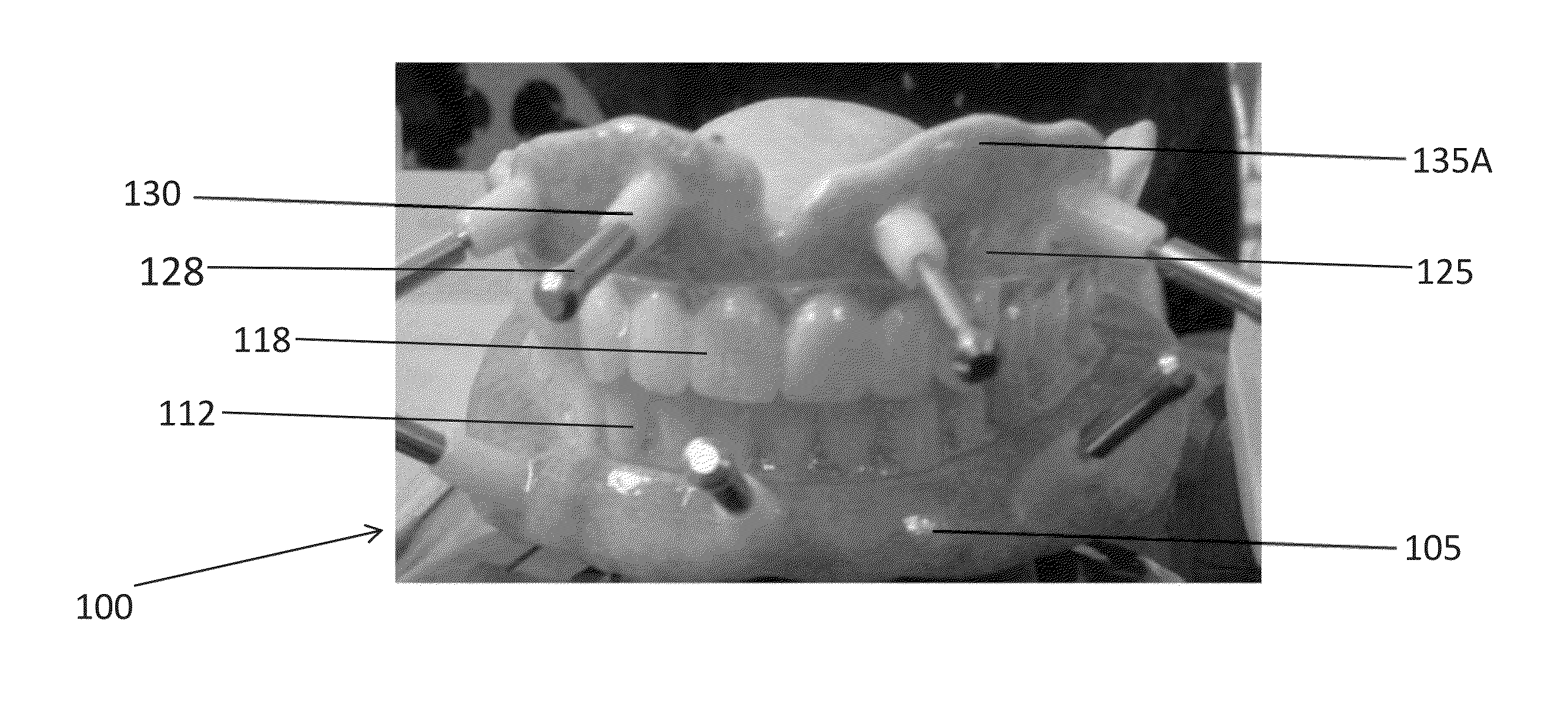

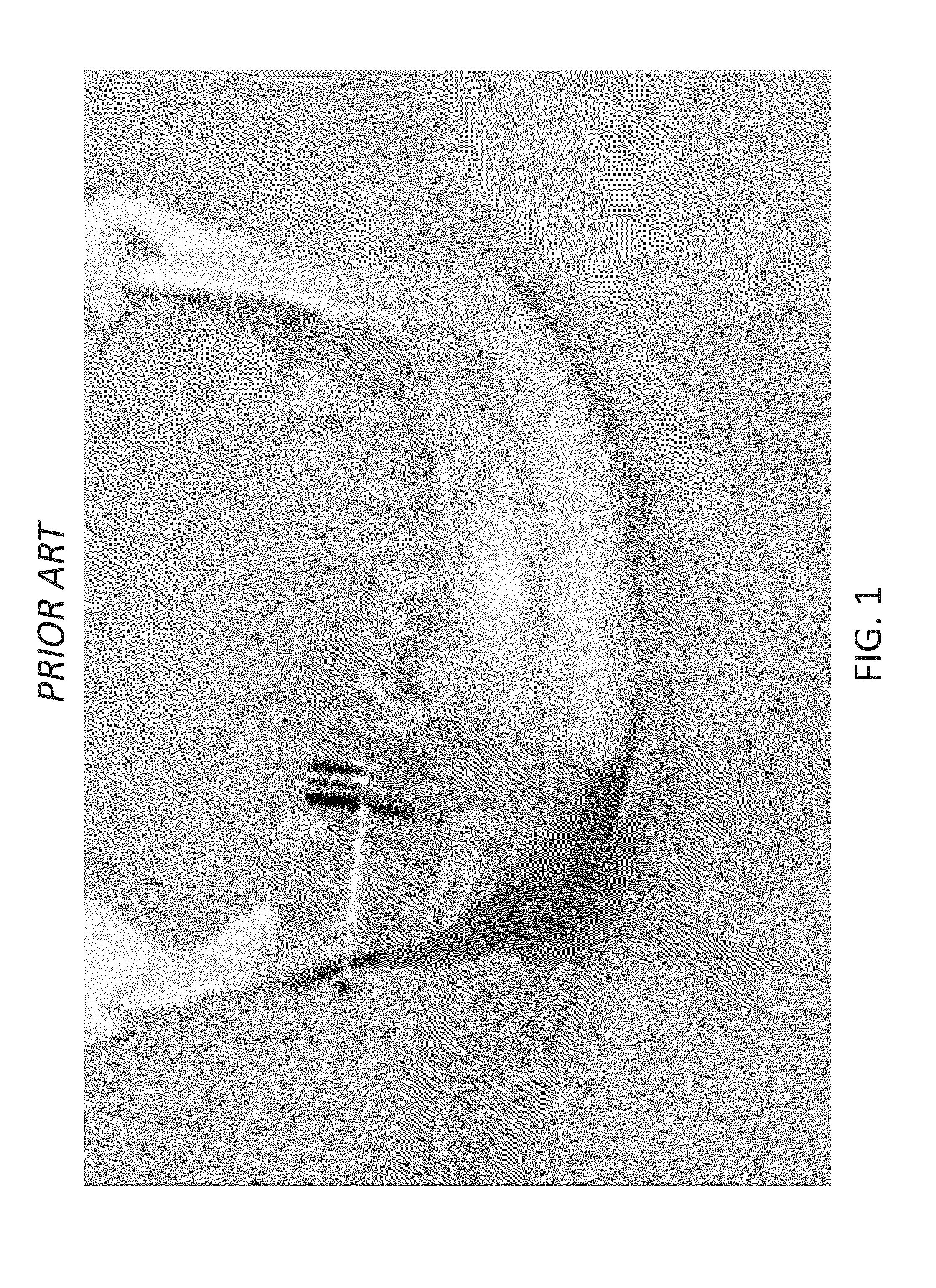

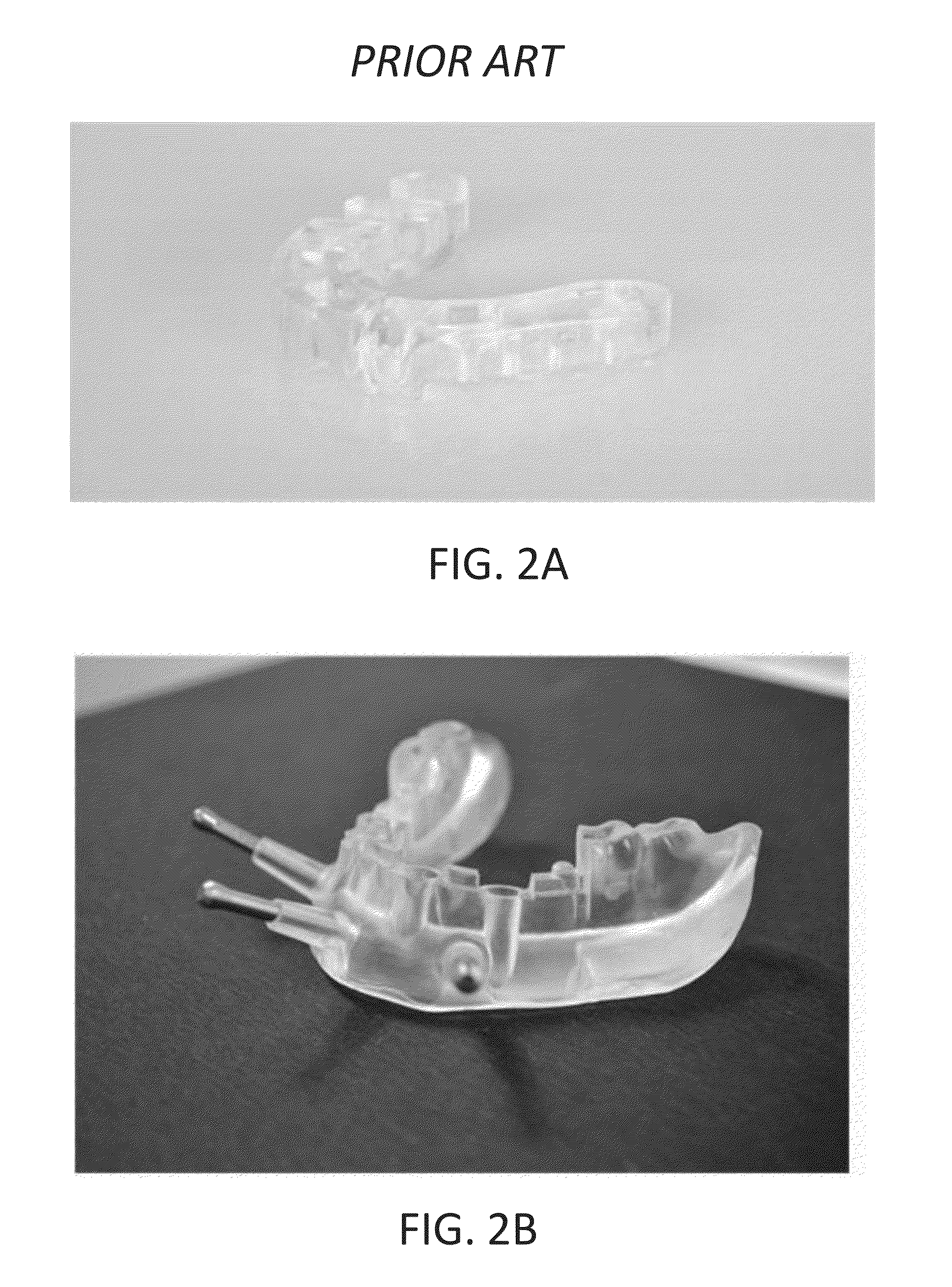

[0089]In one embodiment, the present invention is a two-part denture prosthesis or device comprising a surgical template or guide and removable false teeth set for both the mandibular and maxillary jaw. The surgical template and false teeth set may be configured to fit together in an interlocking configuration. The surgical guide may exist as two components that are each configured to fit the top (maxilla) or bottom (mandible) portion of a patient's jaw when placed inside the mouth. The surgical guide may have one or more holes that may serve as drilling sites. The holes may be positioned so that osteotomies may be drilled d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com