Lift Arm and Coupler Control System

a control system and coupler technology, applied in mechanical machines/dredgers, analogue processes for specific applications, instruments, etc., can solve problems such as limited adaptability to changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

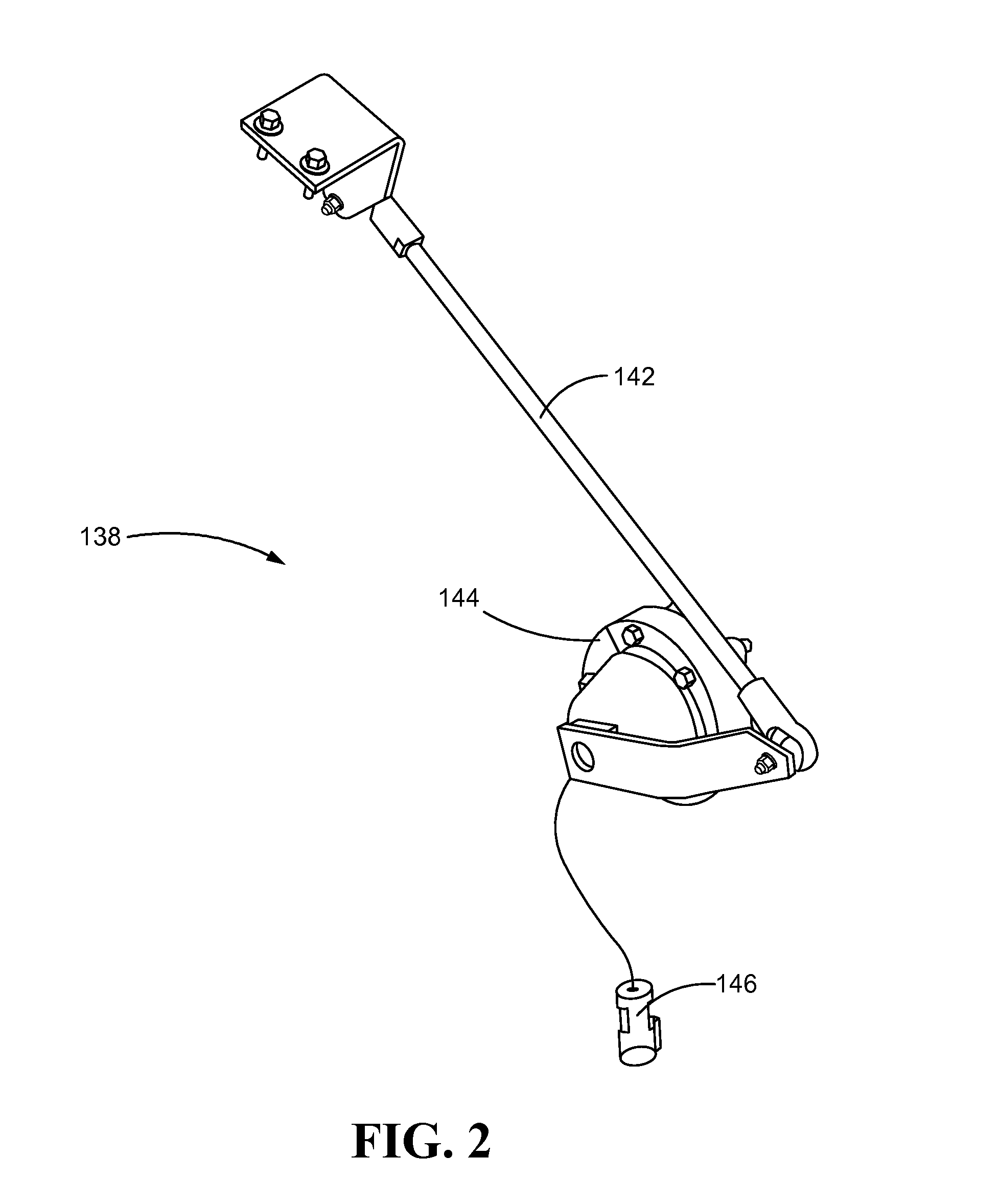

[0017]Reference will now be made in detail to specific embodiments or features, examples of which are illustrated in the accompanying drawings. Generally, corresponding reference numbers will be used throughout the drawings to refer to the same or corresponding parts.

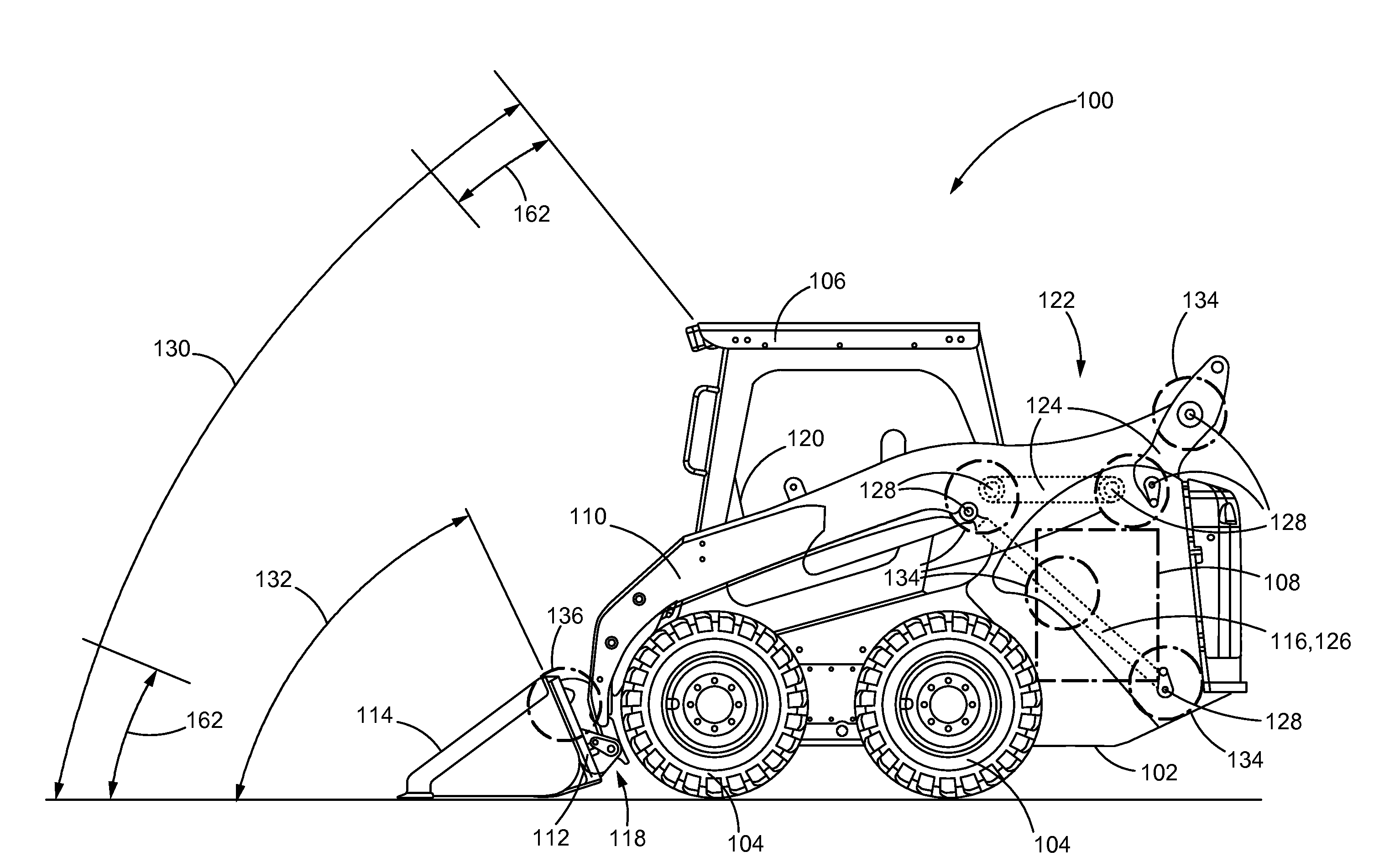

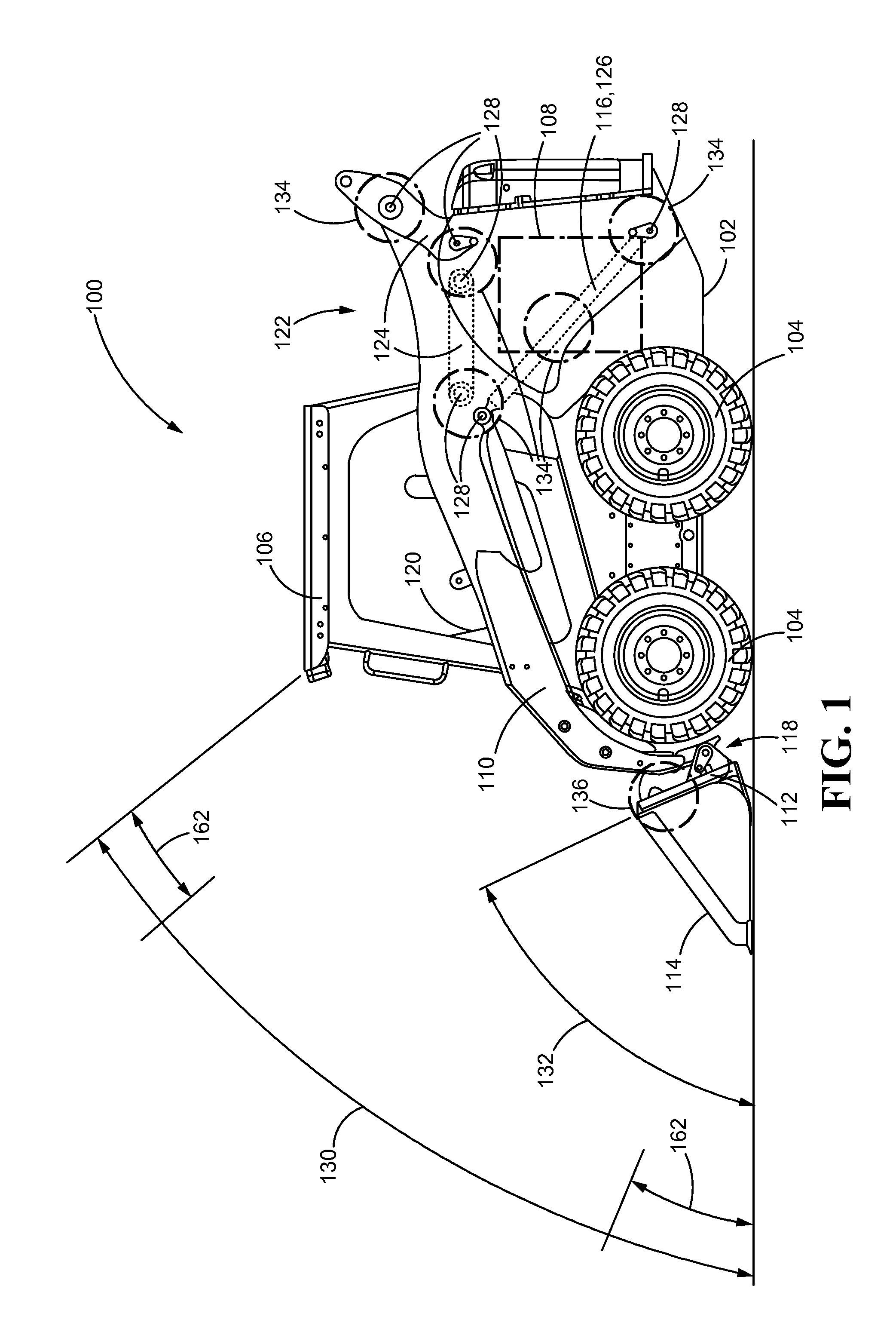

[0018]Referring now to FIG. 1, one exemplary machine or loader 100 is provided. As shown, the loader 100 may generally include a frame 102 which supports traction devices 104, a cab 106, and a power source 108, such as a hydrostatic drive or an engine, and the like. The loader 100 may further include one or more lift arms 110 that are movably coupled to the frame 102 and a coupler 112 that is pivotally coupled or mounted to the working end of the lift arms 110 to which a suitable implement 114, such as a bucket, or the like, may be attached. In particular, the coupler 112 may employ pins, latches, hooks, fasteners, or any other suitable mechanism for interchangeably or non-interchangeably coupling an implement 114 to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com