Expandable Bolt With Thrust Element

a technology of thrust element and expandable bolt, which is applied in the field of expandable bolt with thrust element, can solve the problem of reducing the effective length of the bor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

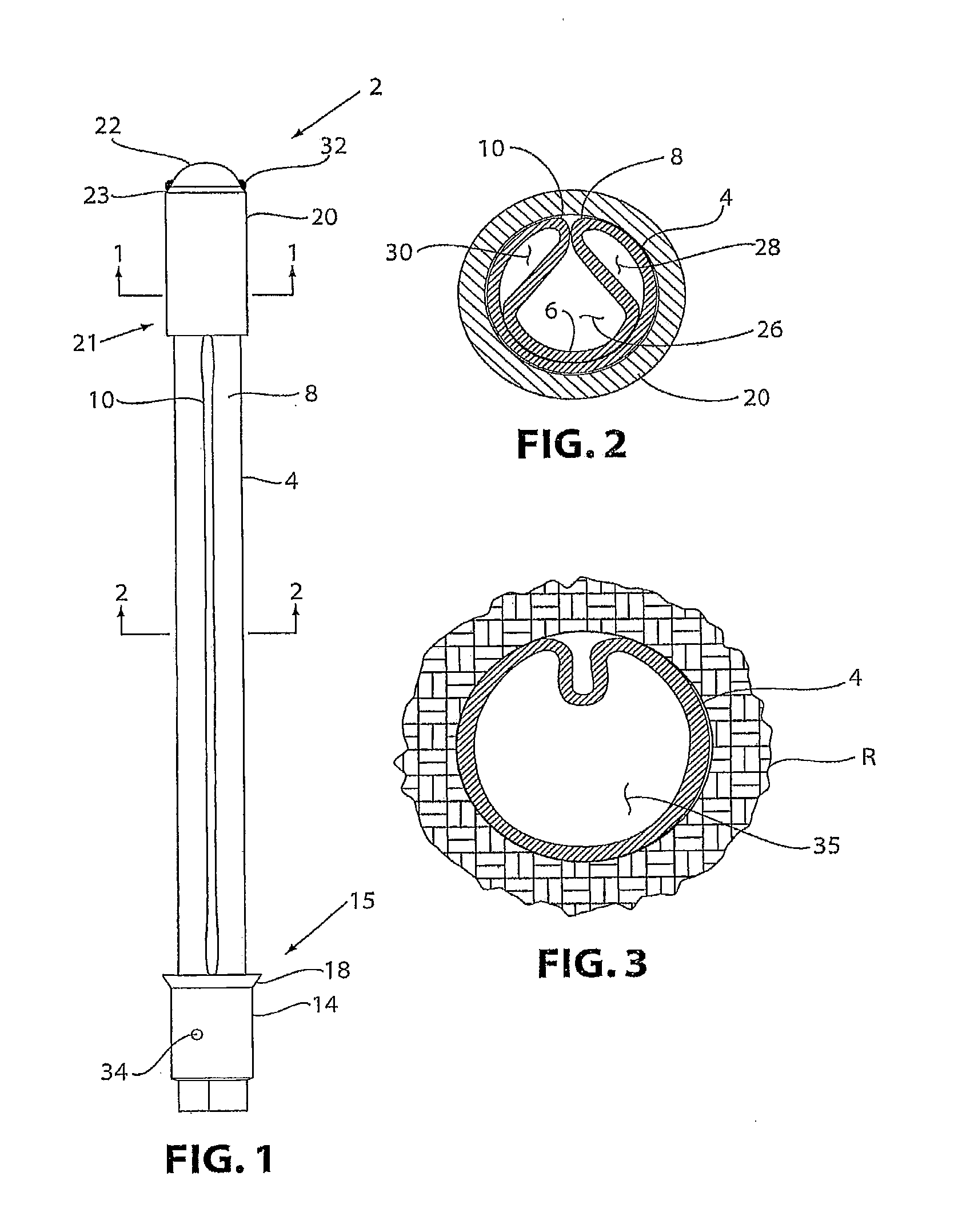

[0035]Referring now to the drawing figures in which like reference numbers refer to like elements, FIG. 1 shows a rock bolt 2 which includes an expandable tube 4 having an initial cross-sectional profile as shown in FIG. 2. The tube 4 is partially collapsed upon itself (such as by rolling or drawing) so as to provide a depressed region 6 between two curved outer portions 8, 10 extending longitudinally along the tube 4. The tube 4 is produced from a steel alloy or the like having sufficient strength to function in rock support, even after deformation from internal hydraulic pressure as described below. A first stiffening tube 14, having a sidewall and two open ends, is attached to and surrounds a proximal end 15 of the tube 4. A lip 18 may extend from stiffening tube 14 for engaging with a rock surface when the rock bolt 2 is inserted in the borehole.

[0036]A second stiffening tube 20, having a sidewall and two open ends, is attached to and surrounds a distal end 21 of tube 4 leaving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com