Bolt Buffer and Firearm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

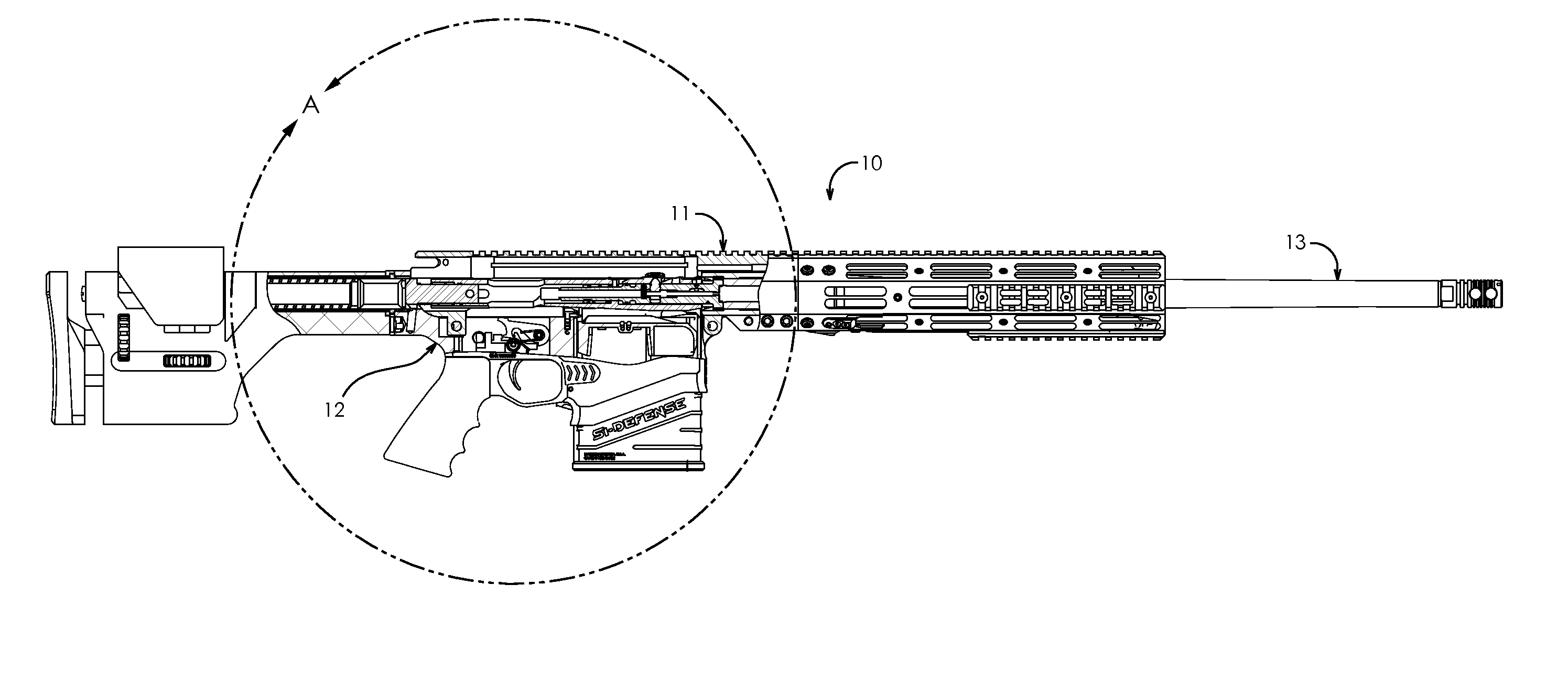

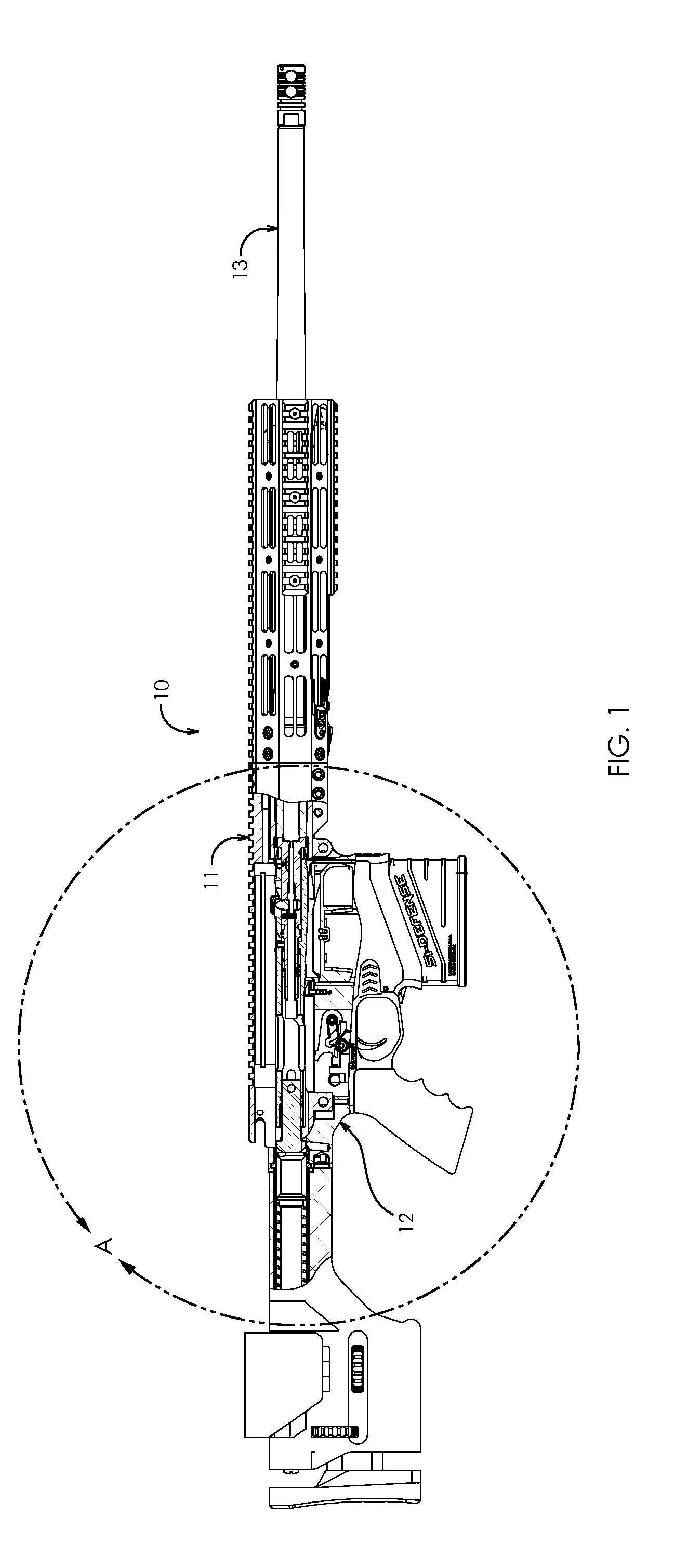

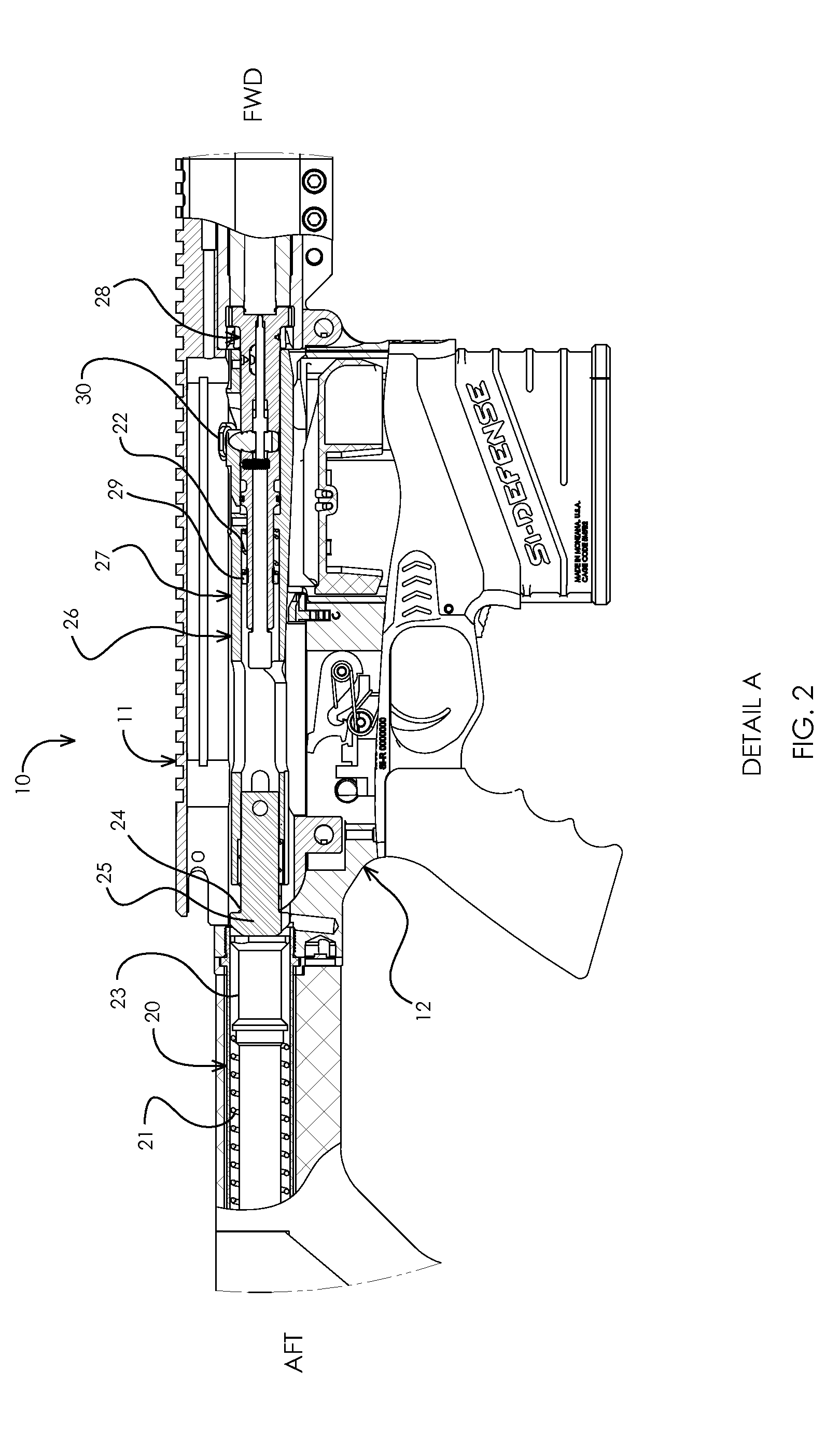

[0006]This invention provides, among other things, firearms and buffer systems, for example, for absorbing the recoil energy of the weapon. Various embodiments provide firearms with an additional buffer spring, for example, aft of the bolt assembly or between the bolt assembly and the carrier assembly. Further, certain embodiments include a buffer adjusting nut, for example, that adjusts preload of at least one buffer spring. Various embodiments provide, for example, as an object or benefit, that they partially or fully address or satisfy one or more of the needs, potential areas for benefit, or opportunities for improvement described herein, or known in the art, as examples.

[0007]In a number of embodiments, more of the recoil energy is absorbed by the firearm rather than by the operator in comparison with certain prior art alternatives. Further, a number of embodiments are more comfortable to operate, particularly when fired repeatedly. Even further, certain embodiments are smoothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com