Control panel cooling device for machine tool

a technology of cooling device and control panel, which is applied in the direction of manufacturing tools, lighting and heating apparatus, and electric apparatus casings/cabinets/drawers, etc., can solve the problems of increasing the number of components of the cooling device, increasing the failure rate of electric components in the path of air blowing from the cooling device, and increasing the temperature inside the control panel. , to achieve the effect of low parts coun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

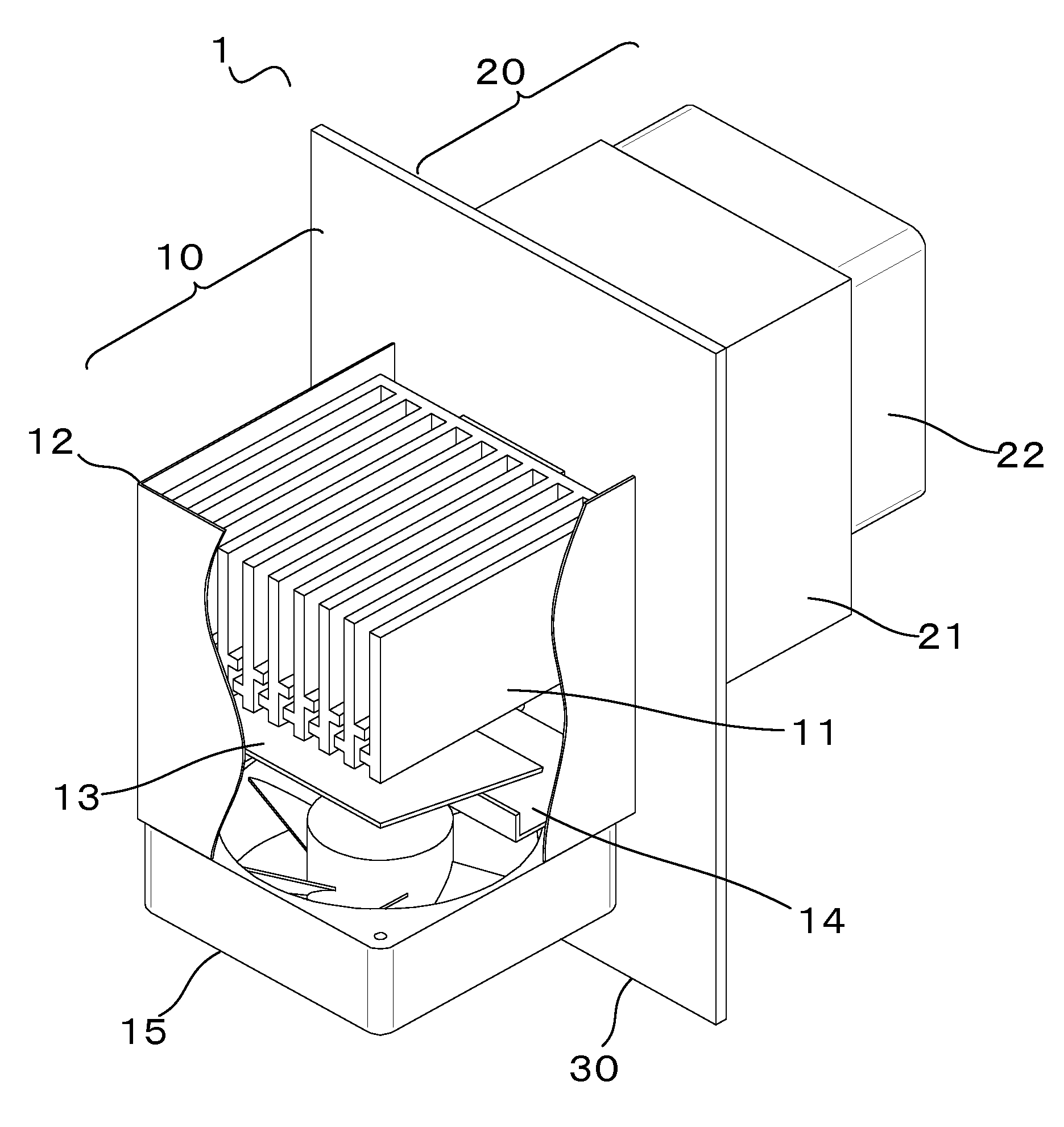

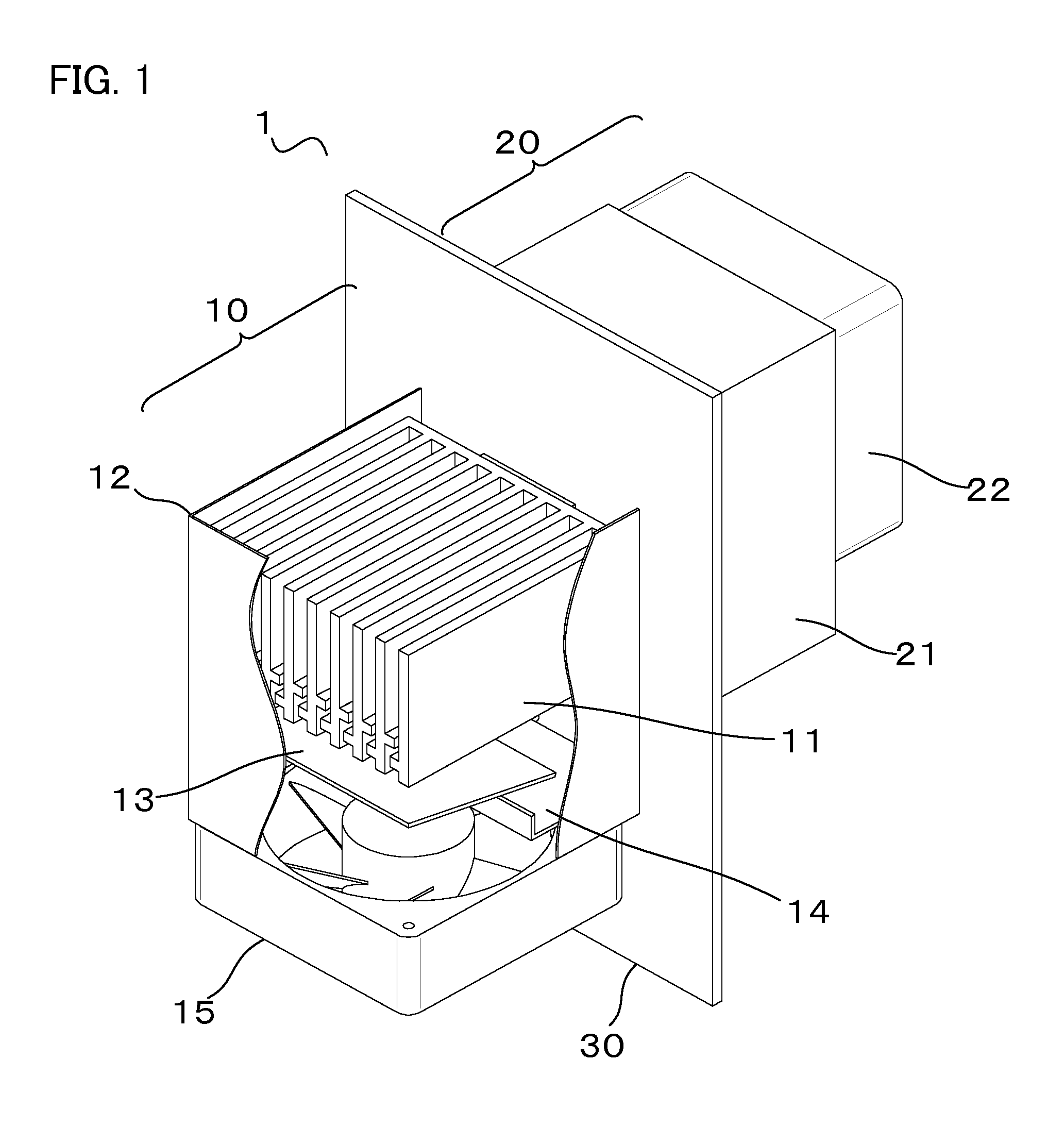

[0021]FIG. 1 is a general view showing a cooling device 1 according to one embodiment of the present invention. The cooling device 1 comprises a cooling unit 10 having a cutting fluid mist collection function and a cooling function and a heat exhaust unit 20 having a heat exhaust function. As shown in FIG. 1, the cooling unit 10 and the heat exhaust unit 20 are mounted on a bracket 30, which is used for attachment to a control panel housing of a machine tool, inside and outside the housing, respectively. The heat exhaust unit 20 will be described in detail later.

[0022]The cooling unit 10 comprises a heat sink 11, cover 12, a droplet guide 13, a tray 14, and a blowing unit 15. As shown in FIG. 1, the heat sink 11, the droplet guide 13, and the tray 14 are mounted so as to be accommodated in the cover 12. Further, the cover 12 is open at its upper end and the blowing unit 15 is attached to its lower end.

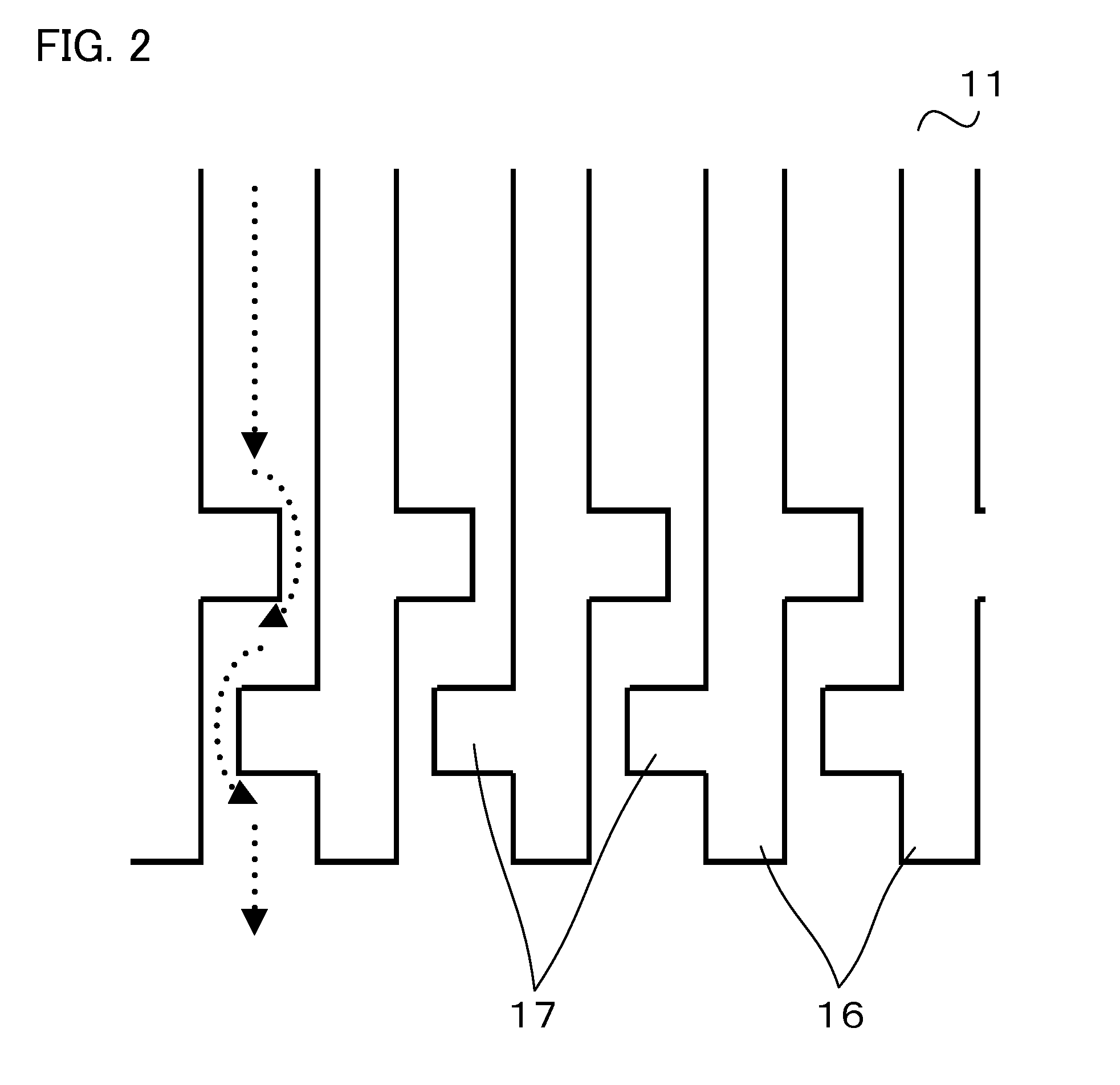

[0023]The heat sink 11 has a function of cooling an ambient atmosphere introduced....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com