Multi-layer safety helmet assembly

a safety helmet and multi-layer technology, applied in helmets, helmet covers, protective garments, etc., can solve the problems of batters being hit by pitches, injuries may become more apparent, and injuries may continue to occur, so as to reduce bulk, reduce bulk, and improve visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The above description is given by way of example, and not limitation. Given the above disclosure, one skilled in the art could devise variations that are within the scope and spirit of the invention disclosed herein, including various ways of forming an outer shell / inner shell of the helmet assembly, and different constructions of the vibration dampeners and / or the use of different types of resilient materials or components. Further, the various features of the embodiments disclosed herein can be used alone, or in varying combinations with each other and are not intended to be limited to the specific combination described herein. Thus, the scope of the claims is not to be limited by the illustrated embodiments.

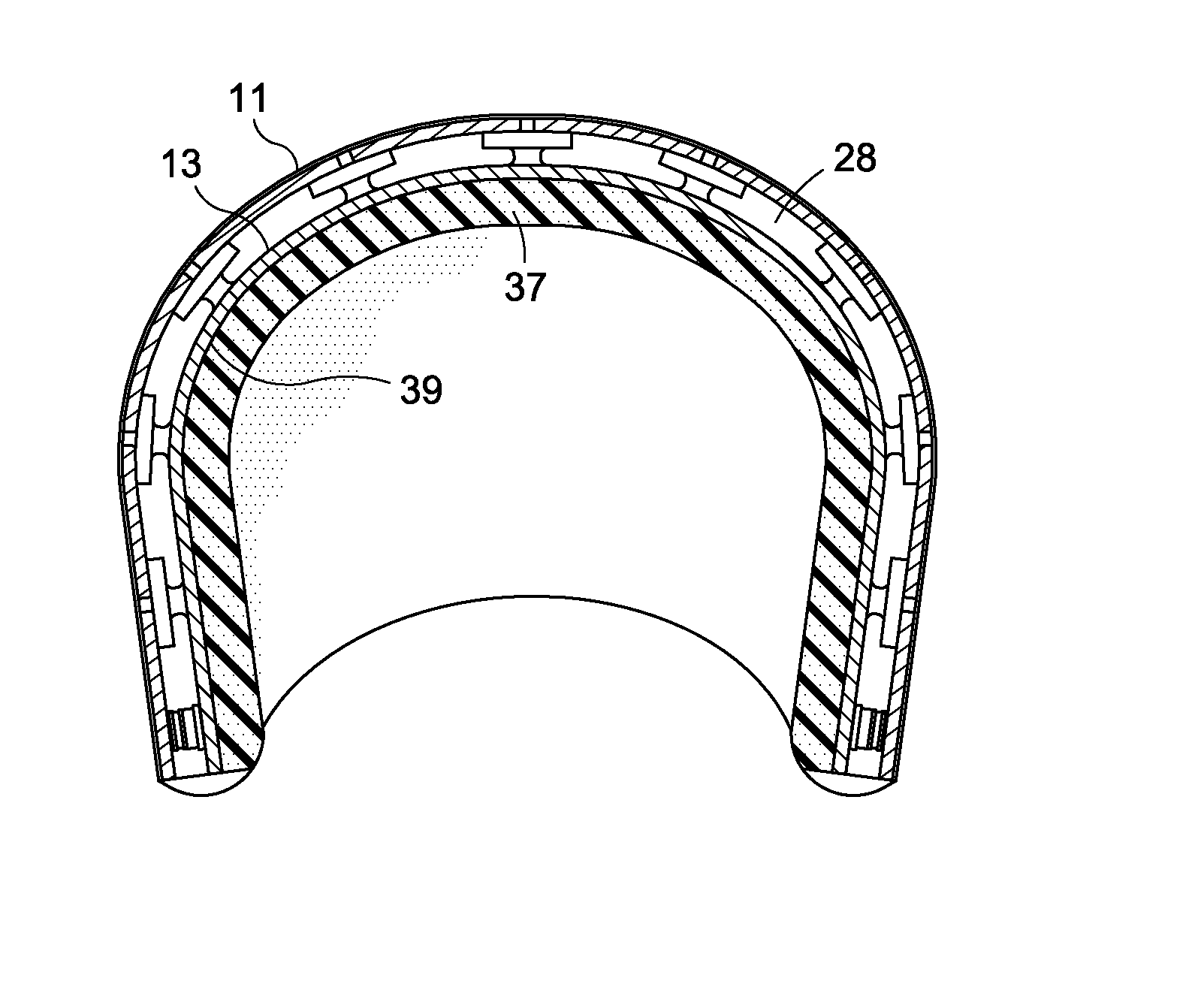

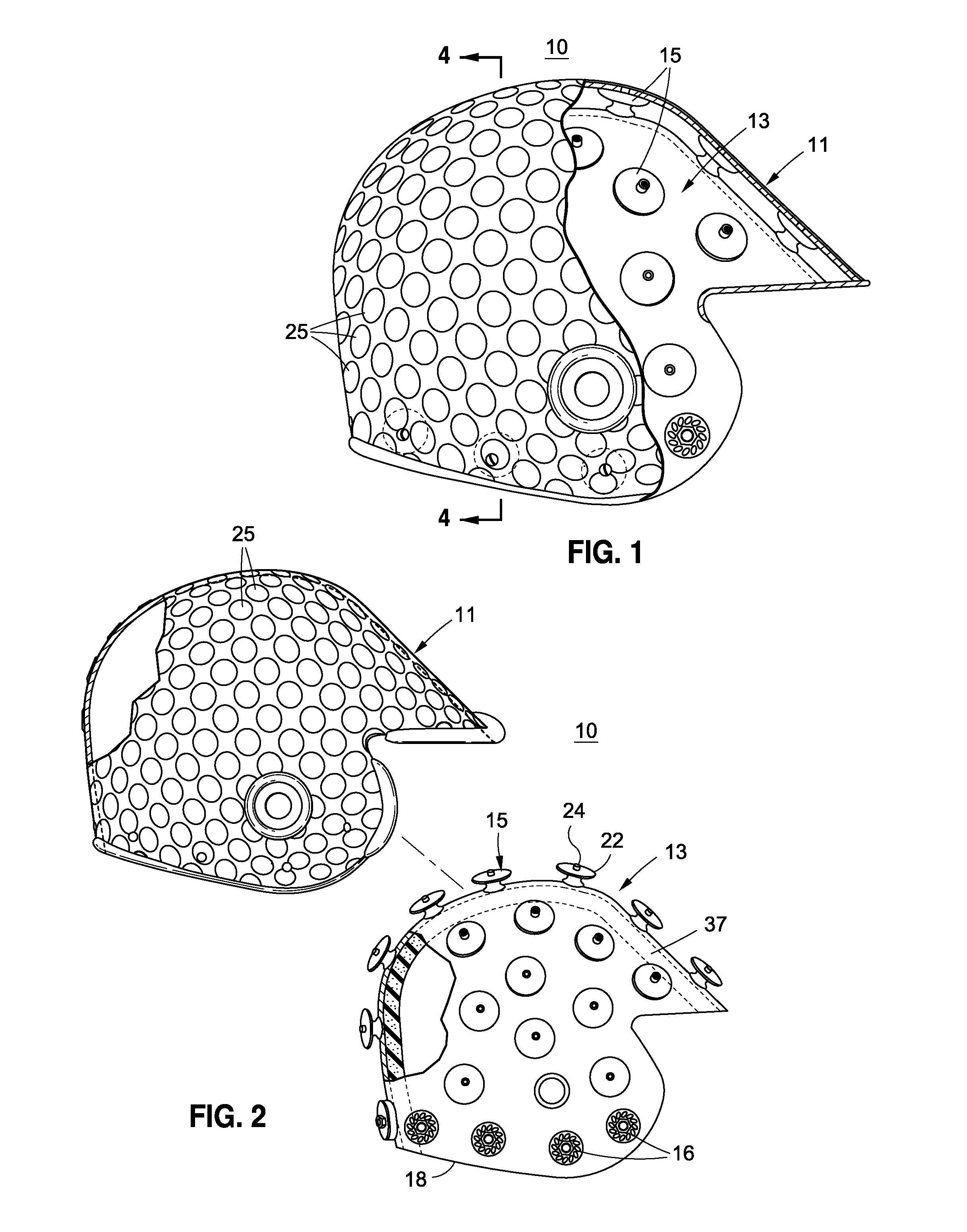

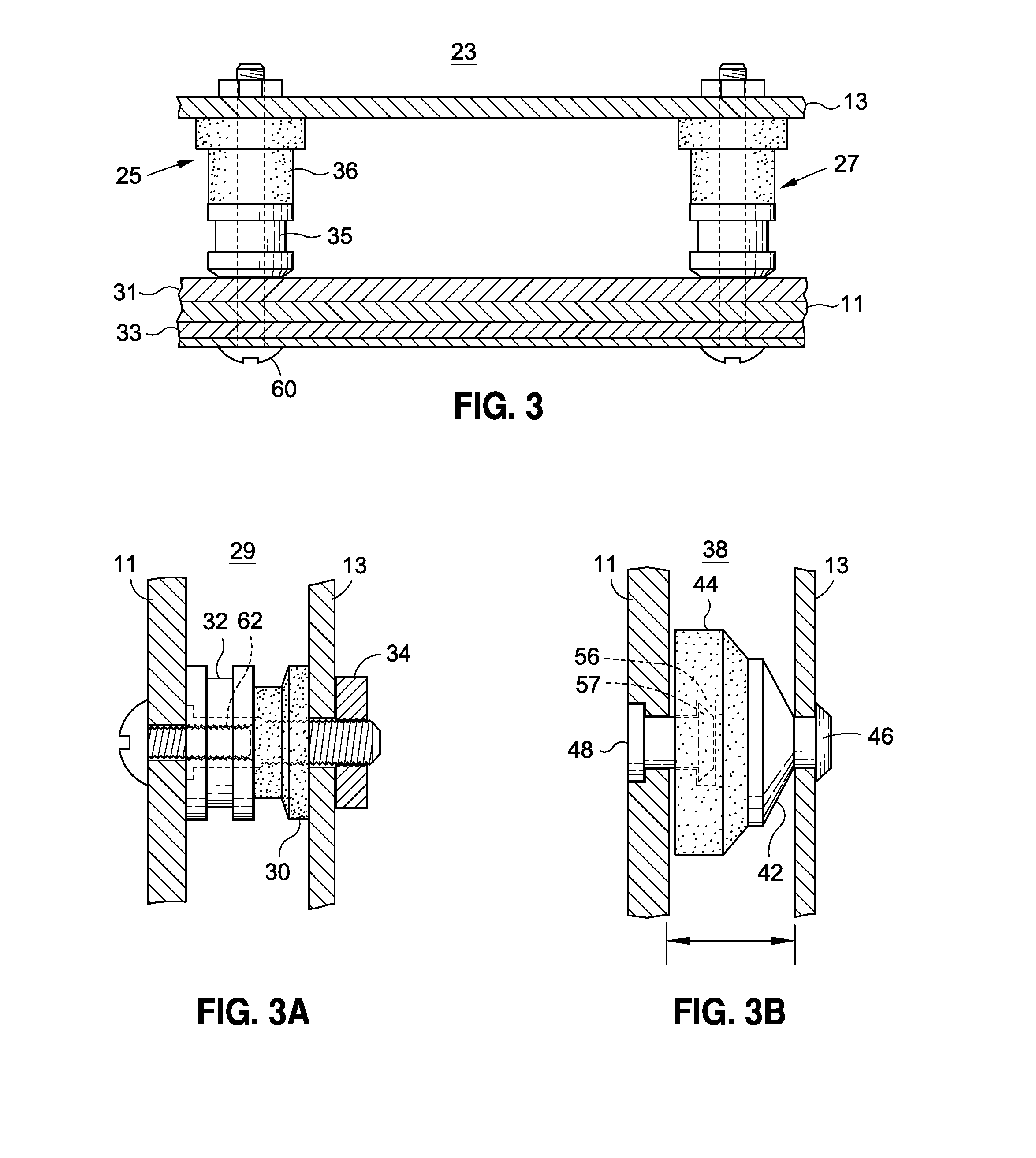

[0035]Referring to the drawings, FIGS. 1 and 2 illustrates an exemplary embodiment of a multilayer safety helmet assembly 10. As shown therein, the helmet assembly 10 includes a helmet outer shell 11, a helmet inner shell 13 and an array of vibration dampeners 15 dispose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com