Sinter paste with coated silver oxide on noble and non-noble surfaces that are difficult to sinter

a technology of silver oxide and noble and non-noble surfaces, which is applied in the direction of synthetic resin layered products, natural mineral layered products, solid-state devices, etc., can solve the problems of difficult contact between components, difficulty in connecting components such as leds or very thin silicon chips, and disadvantageous adhesive technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

Production of the Mixtures

[0147]Initially, the mixtures according to the present invention were produced by, mixing the ingredients at the quantitative ratios given in Table 1.

[0148]The coating of the coated silver oxide particles accounted for 0.8% by weight of the total weight of the coated silver oxide particles.

[0149]A mixture of stearic acid and lauric acid at a mass ratio of 75 to 25 (stearic acid lauric acid) was used as the coating.

[0150]Silver oxide particles having a primary particle size of 1 μm, as determined by means of scanning electron microscopy, were used as metal oxide particles. α-Terpineol was used as a dispersing agent.

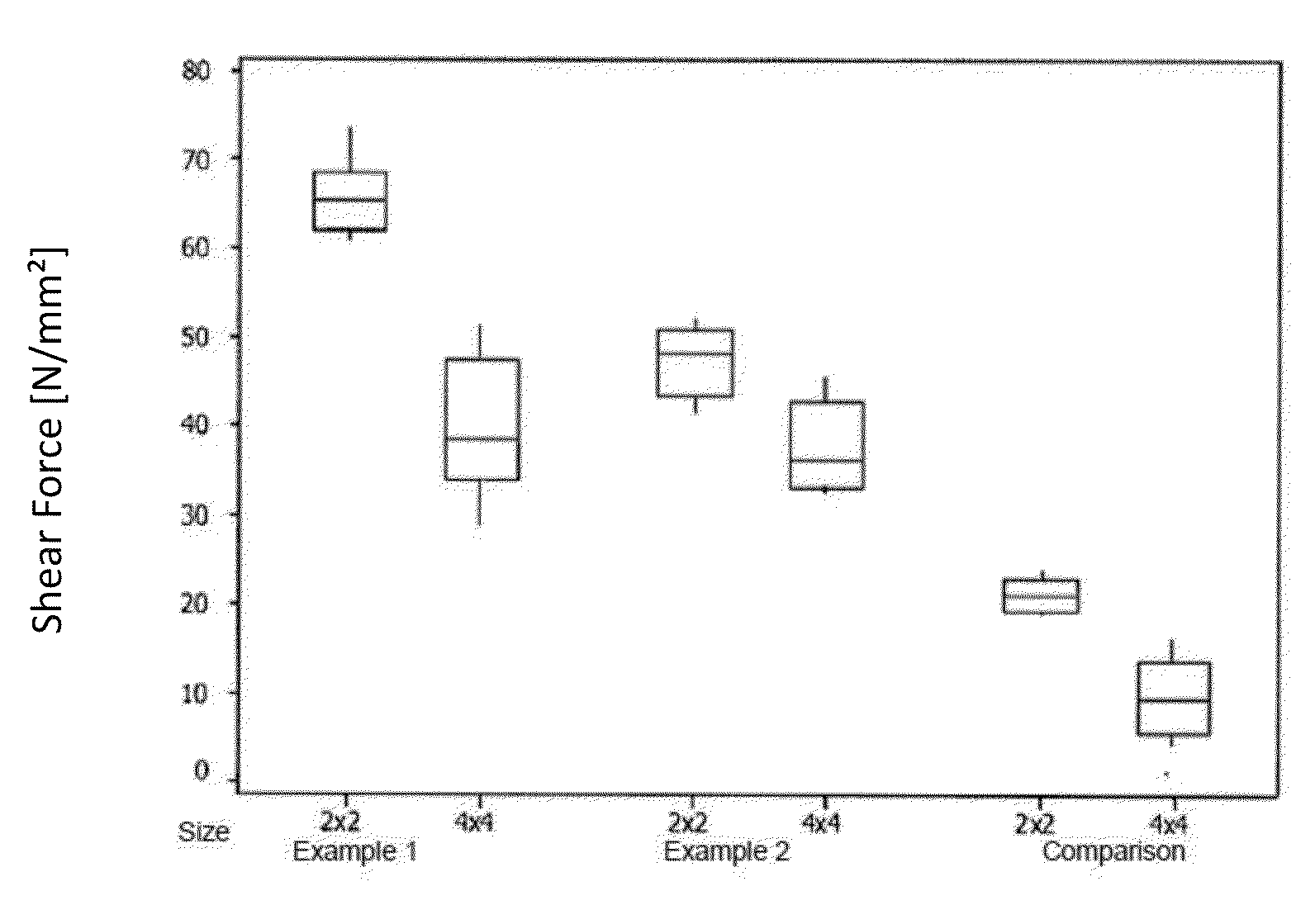

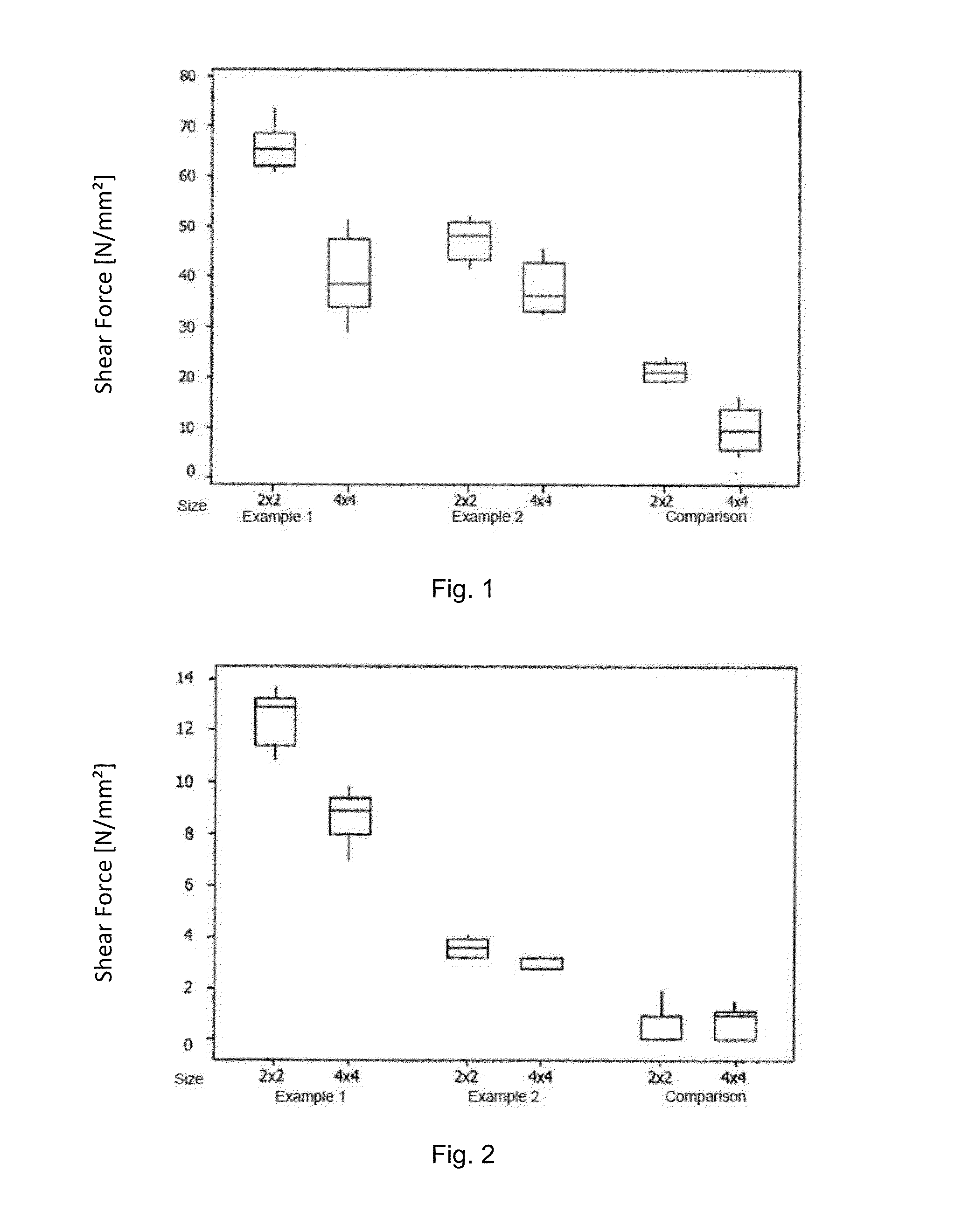

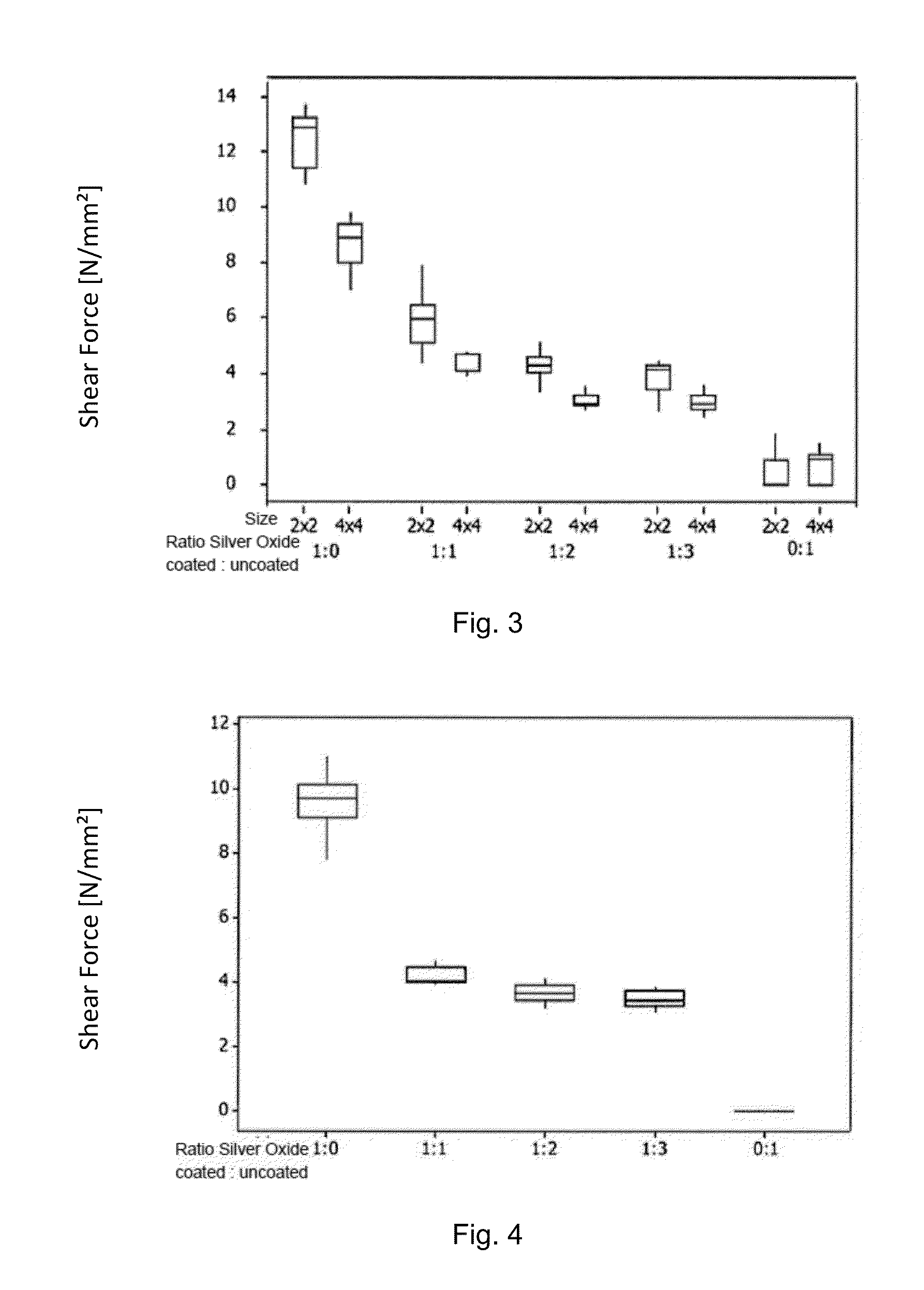

TABLE 1Example 1Example 2Reference Exampleα-Terpineol15.7220.46617.447Ethylcellulose N1000.560.7760.516Silver oxide-coated183.72——Silver oxide-coated2—78.758—Not silver oxide-——82.037coated3Total1001001001The coating was done by jet milling. The agglomerates of the coated silver oxide particles had an average size of 3 μm as determined by means of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap