High Altitude Balloon

a high-altitude balloon and balloon body technology, which is applied in the field of manned and unmanned balloons, can solve the problems of high error margin, high cost, and high complexity of the assembly of gored high-altitude balloons, and achieve the effects of mass production, low cost and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

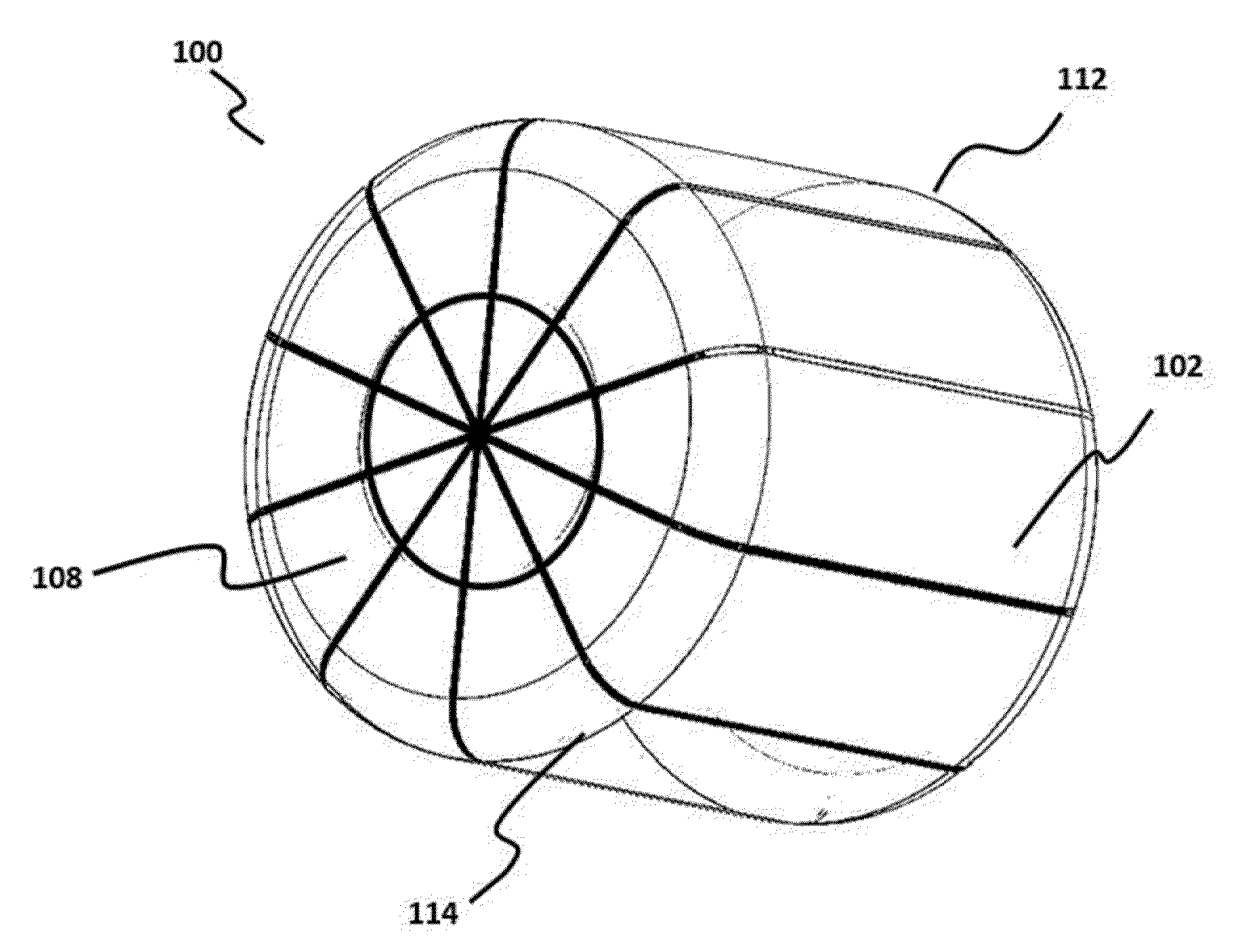

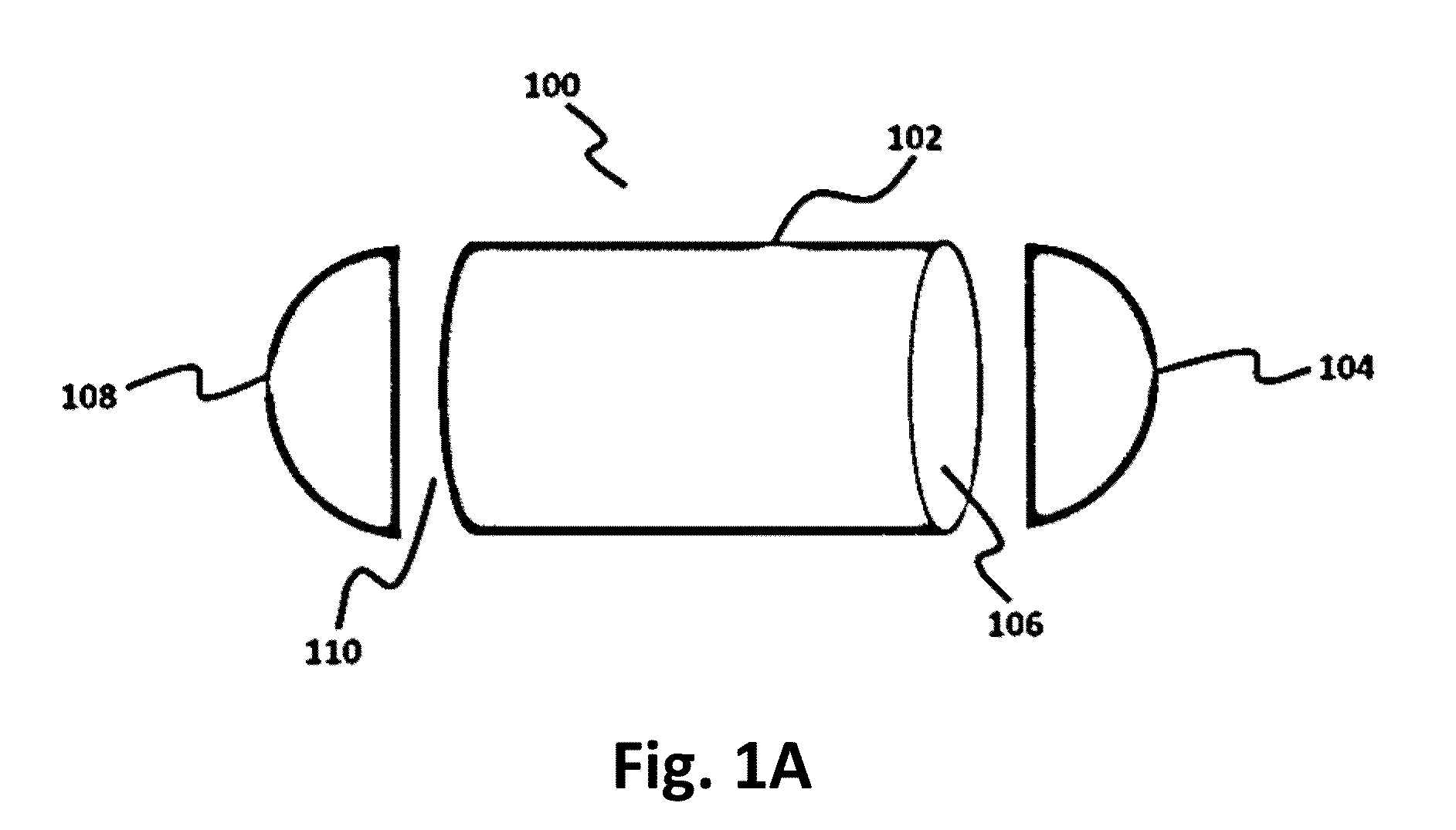

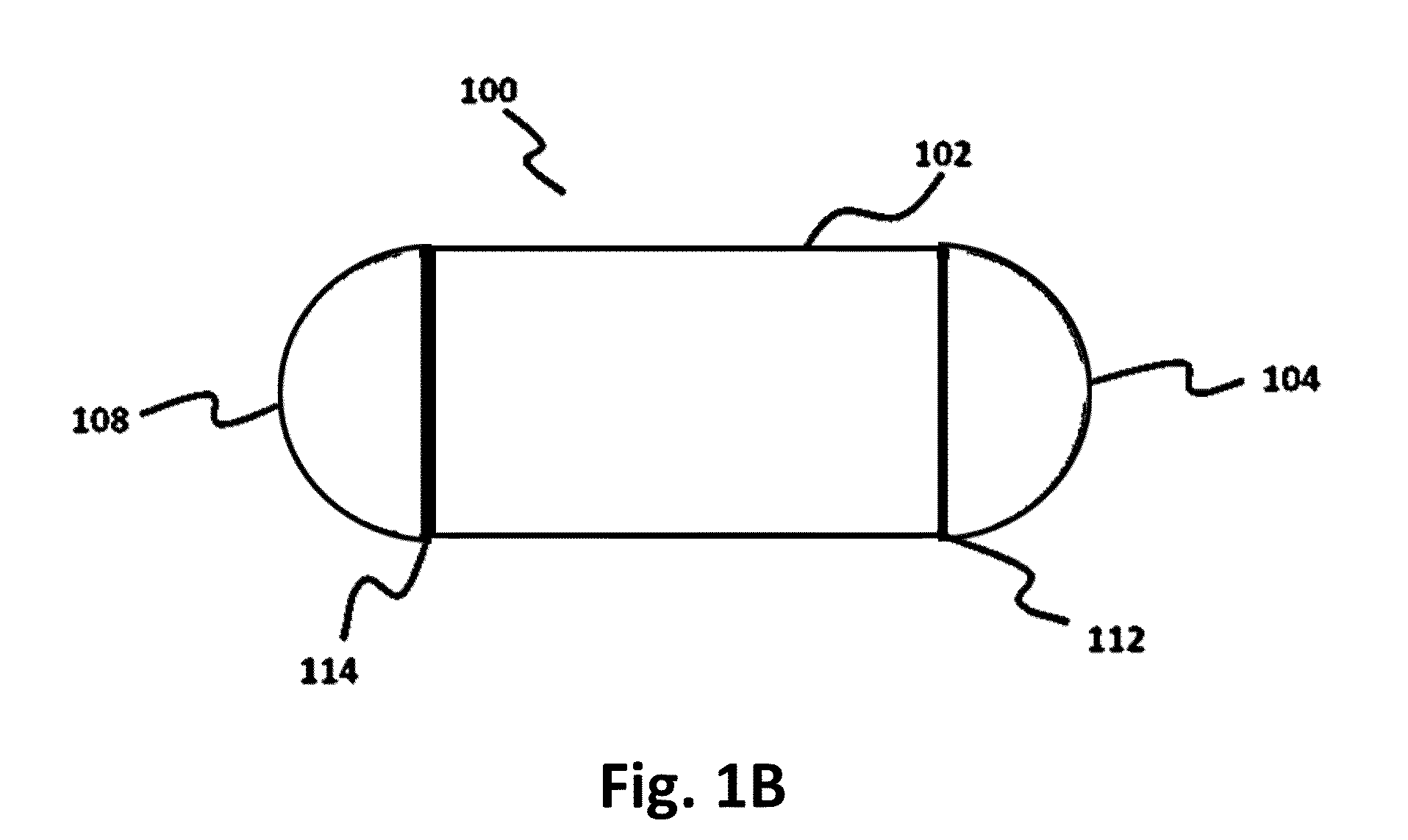

[0042]Embodiments are directed to a high altitude balloon comprised of three parts: a body and two end caps. An embodiment of the high altitude balloon includes a substantially cylindrical body formed with a single rectangular sheet of thin membrane material. The end caps can be made of the same thin membrane material, or they may be made from a different material. The end caps may have a substantially hemispherical (dished) shape or flat (disc) shape, though the end caps may have different shapes. Load restraints may be used on the inside or outside of the balloon body to form a plurality of lobes on the balloon body.

[0043]Embodiments of the high altitude balloons described herein consist of three pieces: a cylindrical body, a first end cap, and a second end cap. This is in contrast to prior high altitude balloons comprised of a body having a plurality of gores attached to each other. As noted above, the term “gore” refers to a tapering sector of a curved surface, such as the taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com