Prefabricated structure for use in constructing outdoor fireplaces and the like and method of making same

a technology for outdoor fireplaces and prefabricated structures, which is applied in the direction of metal-working equipment, domestic stoves or ranges, lighting and heating equipment, etc., can solve the problems of lack of structural integrity of units, cost of on-site construction, and structural failure, and achieve efficient low-cost production and quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

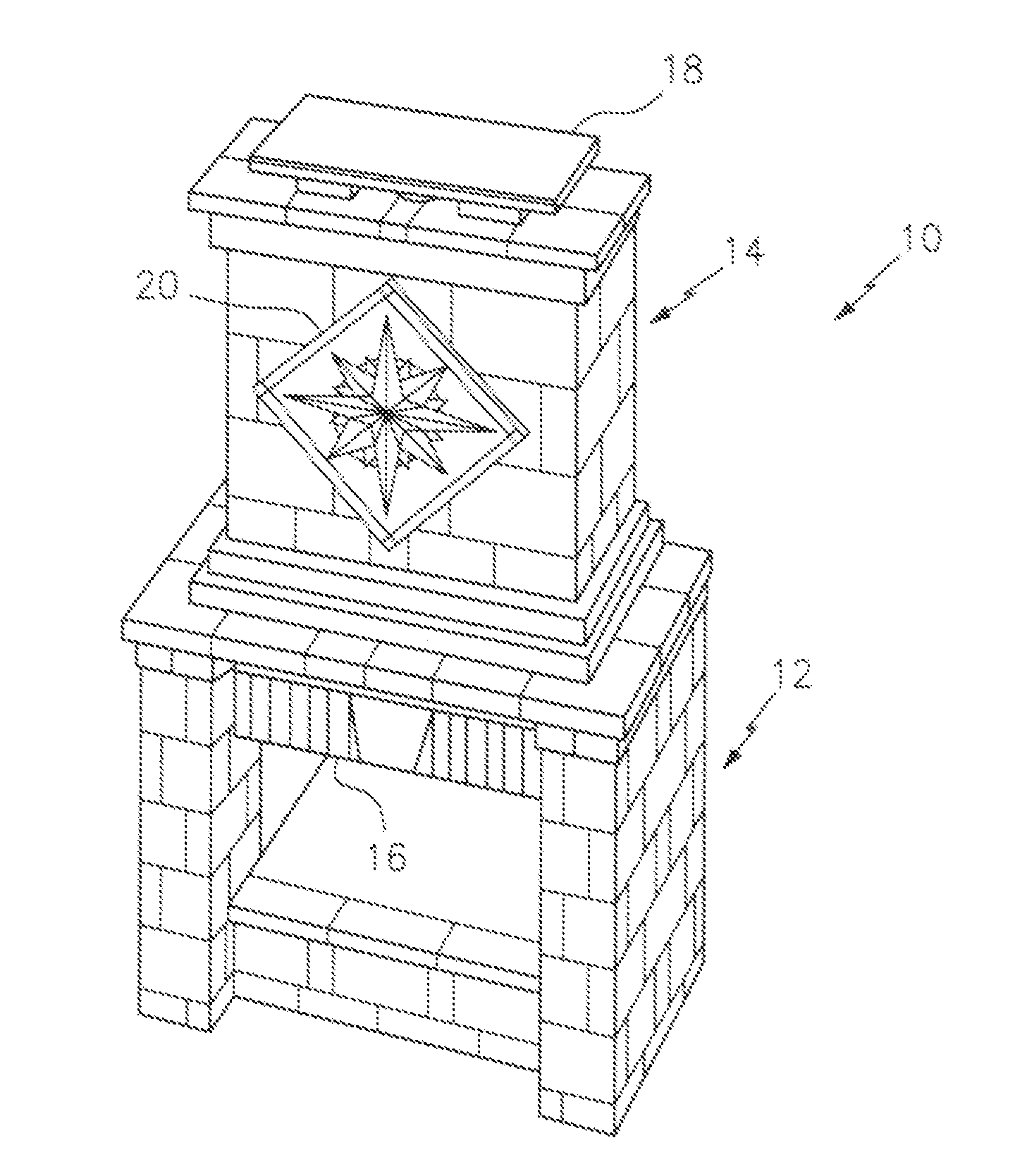

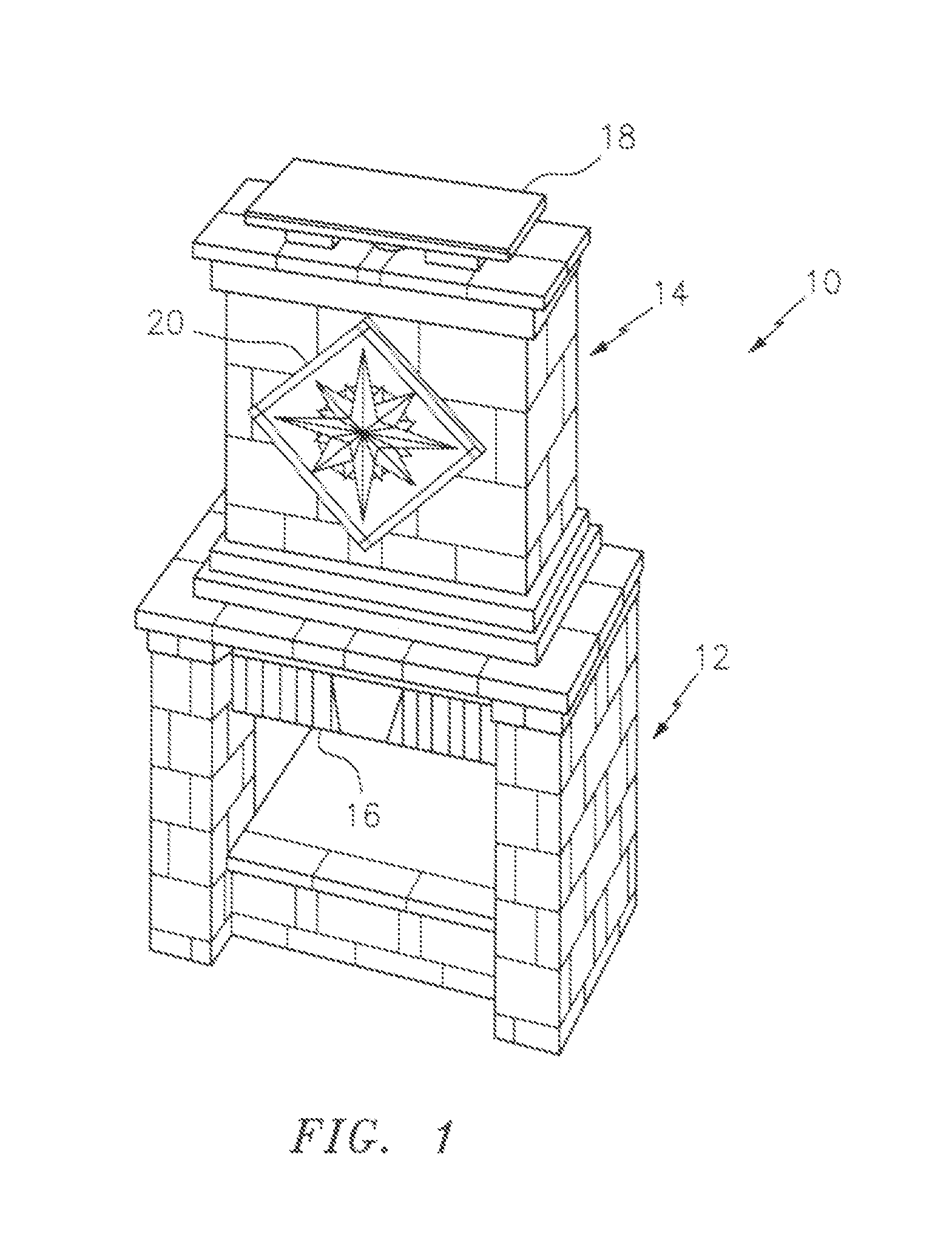

[0023]Referring particularly to FIG. 1 of the drawings, an outdoor fireplace is indicated generally at 10 with a lower unit 12 and an upper unit 14, the lower unit 12 having a conventional front opening 16 and the upper unit 14 having a cap 18 and a vertical through opening internally and serving as a chimney for the lower unit which is open at the top. The fireplace is constructed of concrete blocks with exposed aesthetic surfaces and a decorative emblem 20 may be included on the face of the upper chimney unit 14.

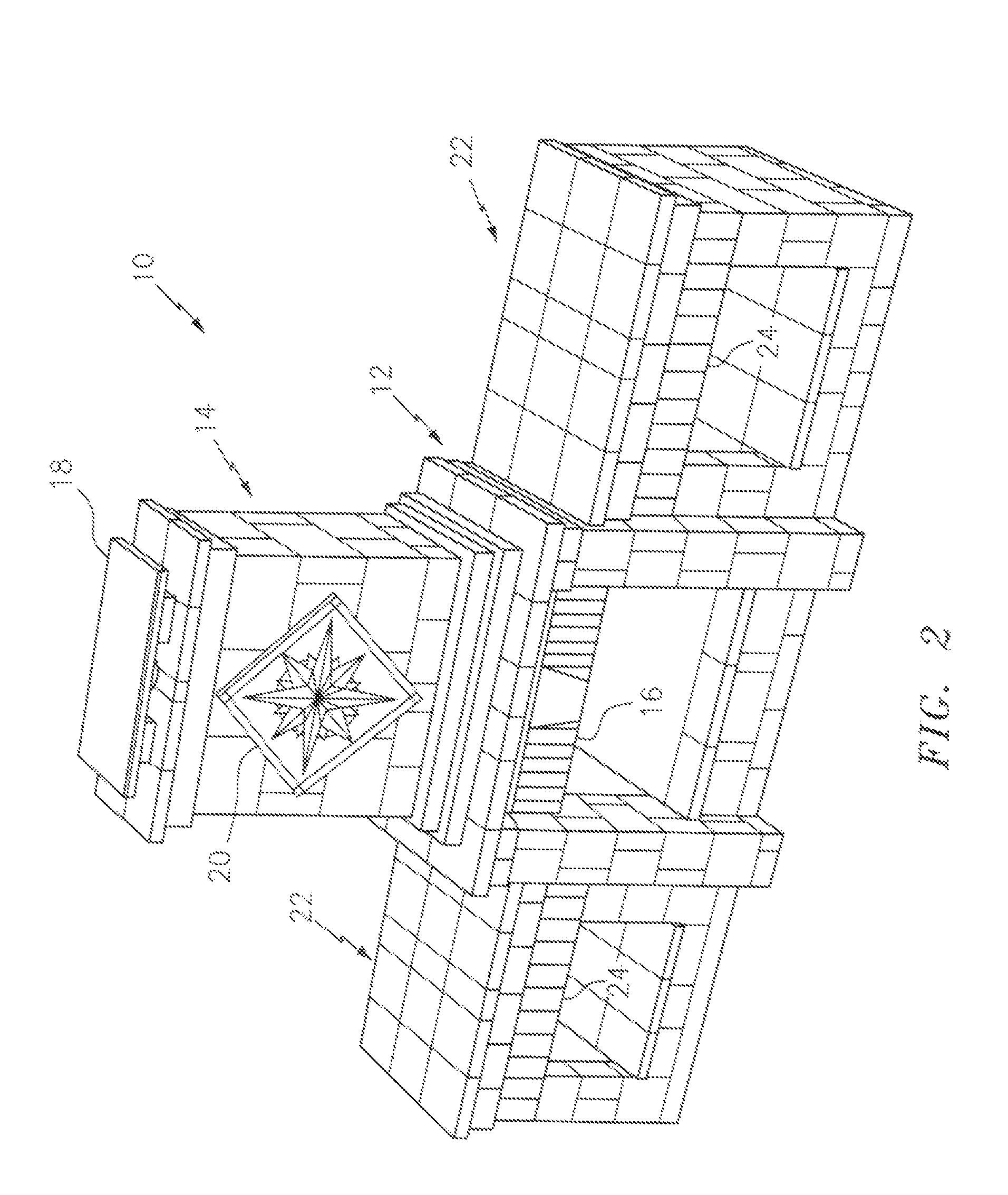

[0024]In FIG. 2 the FIG. 1 fireplace is shown in association with left and right hand wood storage units 22, 22. The wood storage units 22, 22 are of similar construction with aesthetically pleasing concrete blocks and each is provided with a front opening 24 readily accessible for the storage of wood to be used in the fireplace.

[0025]FIG. 3 illustrates a somewhat larger unit 26 which may comprise similar units 28, 28 in side-by-side adjacent relationship with a unitary to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com