Warp knitting elastic fabric and method of fabricating therefore

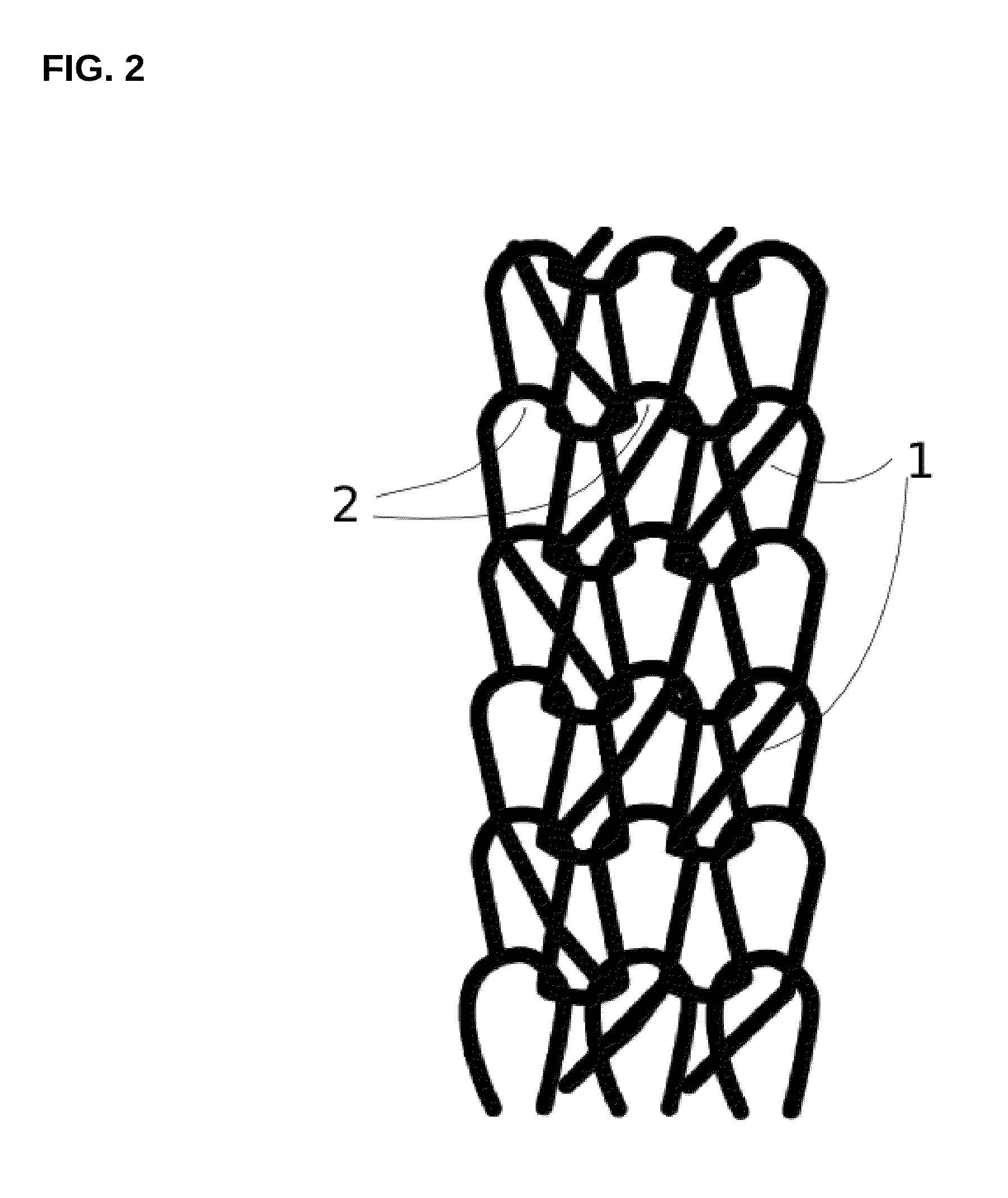

a technology of elastic fabric and yarn, applied in the field of knitted fabric, can solve the problems of poor color fastness, insufficient elasticity, and exposure of spandex yarn to the surface, and achieve the effects of wide density range, good resistance to snagging, and sufficient elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Warping of the Yarns

(1) Warping of Chemical Filament Yarns;

[0011]Warping machine: Karl Mayer DS 21 / 30 NC-2, passive feeding mode.

[0012]Warping temperature: 23° C.; Warping humidity: 65%.

[0013]The process parameters should be set according to the above temperature and humidity conditions.

(2) Warping of Spandex Yarns:

[0014]Warping machine: Karl Mayer DSE-H21 / 30 NC-2, with positive feeding mode.

[0015]Warping temperature: 24° C.; Warping humidity: 78%.

[0016]The process parameters should be set according to the above temperature and humidity conditions.

The Knitting Process

[0017]Knitting machine: KarlMayer HKS2-3, HKS2-3E, HKS3-1, HKS4-1, RSE4-1 or any other single needle bar warp knitting machine.

[0018]Machine type region: E28-E50

[0019]Threading mode: full-threading.

[0020]Two types of yarns are used in this fabric: chemical filament and polyurethane fiber.

[0021]The warp knitting process as well as the characterizes of the fabric produced is mainly defined by the lapping moments of the gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com